High-temperature-resistant and strong-emulsification microorganism strain and application of microorganism strain in paraffin removing and preventing

A technology for removing wax and bacterial strains, which is applied in the field of petroleum microorganisms and can solve problems such as poor high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] Screening and Identification of Strains with Preservation Number CCTCCNo: M2015695

[0092] 210 oil and water samples were collected in the oil field, and 18 strains of Qingfangwax were obtained through enrichment culture, and then through directional domestication and compatibility optimization of crude oil, eight strains were finally selected, namely 98-32, 98-11, XG- 2. NG-23, SG-3, G104-5-1, G104-5-2 and G104-5-3.

[0093] Streak the selected strains on the nutrient agar plate, culture at 37°C for 48 hours, place at room temperature for 24 hours to observe and describe the characteristics of the colony and take pictures, select a typical single colony to make hanging drops, and observe its motility; at the same time, use Gram staining, Observe the shape of the cells and measure their size. Electron microscope observation thalline cell flagella situation and taking pictures, the results are shown in Table 1, wherein the photos of the bacterial classification of the ...

Embodiment 2

[0099] The production method of the anti-wax bacteria agent with the preservation number CCTCCNo: M2015695

[0100] A production method for preparing a wax-clearing and anti-wax liquid microbial agent with a preservation number of CCTCCNo: M2015695, the steps are as follows:

[0101] 1) Slant culture: inoculate the strain with deposit number CCTCCNo: M2015695 in the slant medium, and culture at 25-28°C for 3 days.

[0102] The slant medium formula is: 0.5% beef extract, 1.0% peptone, 0.5% NaCl, 1.5%-1.8% agar powder, the balance is water, pH7.2-7.4.

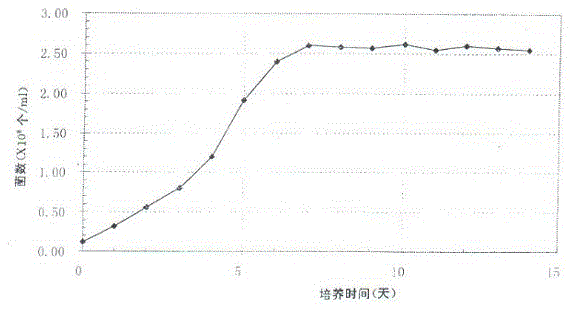

[0103] 2) Shake flask culture: inoculate the cultured strains on the inclined plane into the liquid medium, the inoculum amount is 5-10%, the rotation speed is 140r / min, cultivate at 37°C for 24 hours, pH6.5-7.5, and the bacterial concentration is 2-7× 10 8 pieces / ml.

[0104] The formula of the liquid medium is: liquid paraffin 2.0%, NH 4 Cl0.4%, Na 2 HPO 4 0.4%, KH 2 PO 4 0.4%, MgSO 40.1%, yeast powder 0.001%, the bala...

Embodiment 3

[0113] Performance evaluation of the strain agent with deposit number CCTCCNo: M2015695

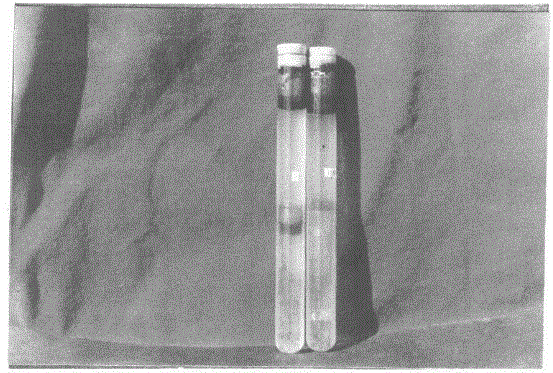

[0114] 1. High temperature resistance

[0115] Inject the bacterial solution into the test tube aseptically, seal it, and treat it at 90°C for 10 days.

[0116] Calculate the number of viable bacteria before and after treatment to obtain the survival rate (%). In the absence of fresh nutrient supply, more than 70% still survive after static treatment at 90°C for 10 days. During the screening process, strains whose survival rate was lower than 70% were eliminated.

[0117] 2. Emulsifying effect on crude oil

[0118] Add 100ml of formation water, a small amount of inorganic salt and 5g of crude oil to a 250ml Erlenmeyer flask, inoculate 10ml of bacterial solution, seal it with a leather stopper, place it in a constant temperature water bath at 65°C for 7 days, and compare it with the blank control to observe the emulsification and dispersion of microorganisms after they act on crude oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com