Hydraulic oil delivery pipe for loader

A technology of hydraulic oil and conveying pipe is applied in the field of hydraulic oil conveying pipe of loader, which can solve the problems of affecting the service life of conveying pipe and the machine wear of conveying pipe, so as to achieve the effect of not easy to wear and easy to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

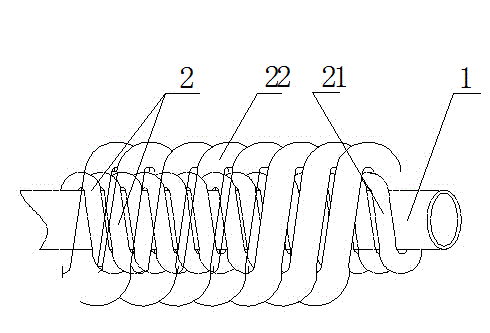

[0011] Such as figure 1 As shown: the loader hydraulic oil delivery pipe, including the pipe body 1, the pipe body 1 is made of rubber, and there is a steel wire mesh in the middle of the pipe body, and the feature is: the pipe body 1 is also wrapped with steel wires 2.

[0012] Further, the steel wires are double-layered, and the coiling directions of the double-layer steel wires are opposite to each other, that is, the inner layer steel wires 21 and the outer layer steel wires 22 .

[0013] Furthermore, the steel wire section is a rectangular structure, and the length of the rectangle is close to the outside of the pipe body.

[0014] During production, the steel wire can also be made into the shape of a spring first, and then the pipe body can be threaded inside. Such a pipe is more wear-resistant and has a longer service life when installed on the loader.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com