Optical lens

An optical lens and lens technology, applied in the field of optical lenses, can solve the problems of low light conversion efficiency, poor spot uniformity, discontinuous light, etc., so as to improve the spot uniformity and light utilization rate, high light conversion efficiency, The effect of a large light angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

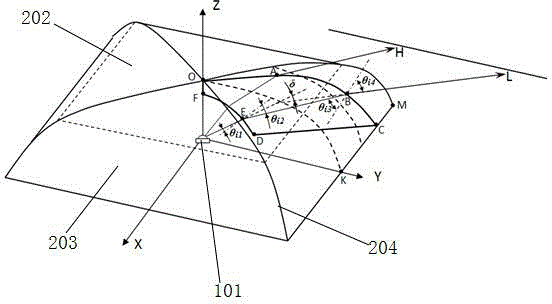

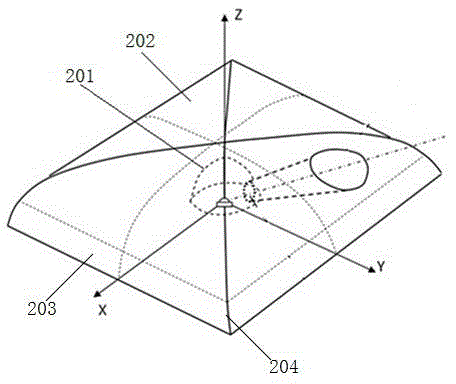

[0038] Such as figure 1 with figure 2As shown, an optical lens includes a convex light incident surface 201, a light exit surface 202, four corner surfaces 204 and four sides 203, and the four sides 203 are arranged in a square on four sides of the light exit surface 202. The four corner surfaces 204 are respectively located at the four corners of the square for refracting or reflecting light, the concave lens is located at the center of the square, the light exit surface 202, the four corner surfaces 204 and The four sides 203 are smoothly connected to form a continuous smooth curved surface in the shape of a cover.

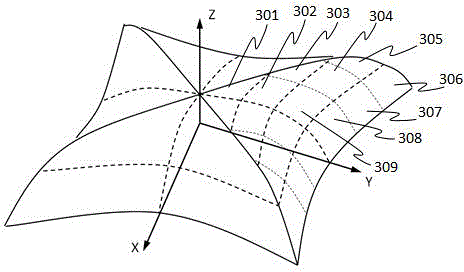

[0039] The hood-shaped continuous smooth curved surface is divided into a first part OA, a second part AB and a third part BC from the center to the outside, and the incident angle k of the light rays entering the air through the first part OA and the second part AB 1 meet k 1 =15°~22°, the incident angle k of incident air through the third part BC 2 meet ...

Embodiment 2

[0053] Such as figure 1 with figure 2 As shown, an optical lens includes a convex light incident surface 201, a light exit surface 202, four corner surfaces 204 and four sides 203, and the four sides 203 are arranged in a square on four sides of the light exit surface 202. The four corner surfaces 204 are respectively located at the four corners of the square for refracting or reflecting light, the concave lens is located at the center of the square, the light exit surface 202, the four corner surfaces 204 and The four sides 203 are smoothly connected to form a continuous smooth curved surface in the shape of a cover.

[0054] The hood-shaped continuous smooth curved surface is divided into a first part OA, a second part AB and a third part BC from the center to the outside, and the incident angle k of the light rays entering the air through the first part OA and the second part AB 1 meet k 1 =15°~22°, the incident angle k of incident air through the third part BC 2 meet...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap