Detection method of generator air-gap static-state eccentric fault orientation and fault degree

A detection method and technology for the degree of failure, applied in the detection field, can solve problems such as difficulty in maintaining and repairing generators, and achieve the effect of facilitating maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

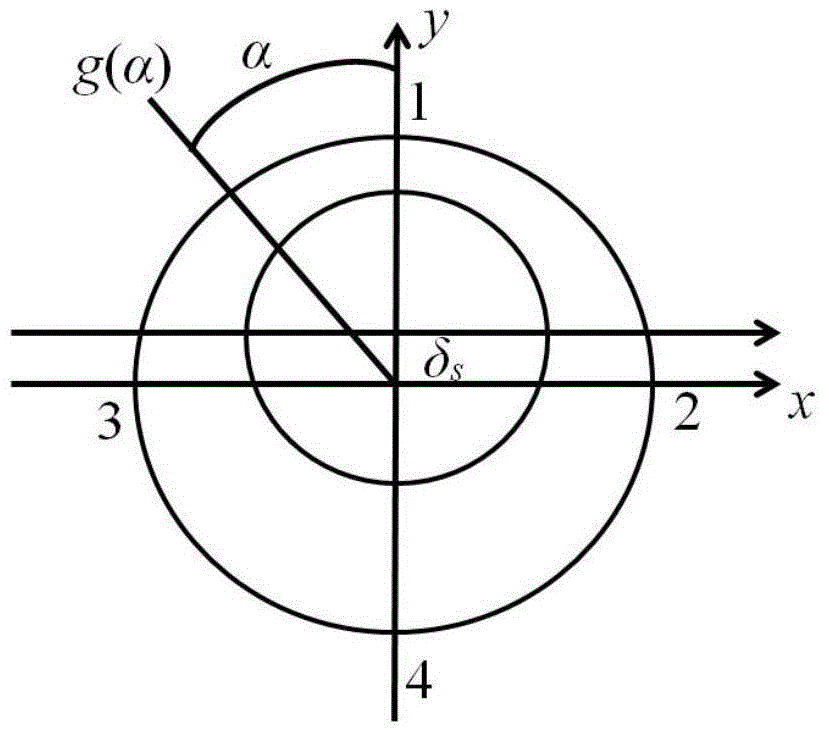

[0028] In order to describe the specific operation process of the detection method of the present invention more accurately and clearly, the applicant explained the principle, implementation process and calculation method of the detection method of the present invention in conjunction with the accompanying drawings. The specific implementation process disclosed below is only illustrative, and does not constitute a particular limitation to the present invention.

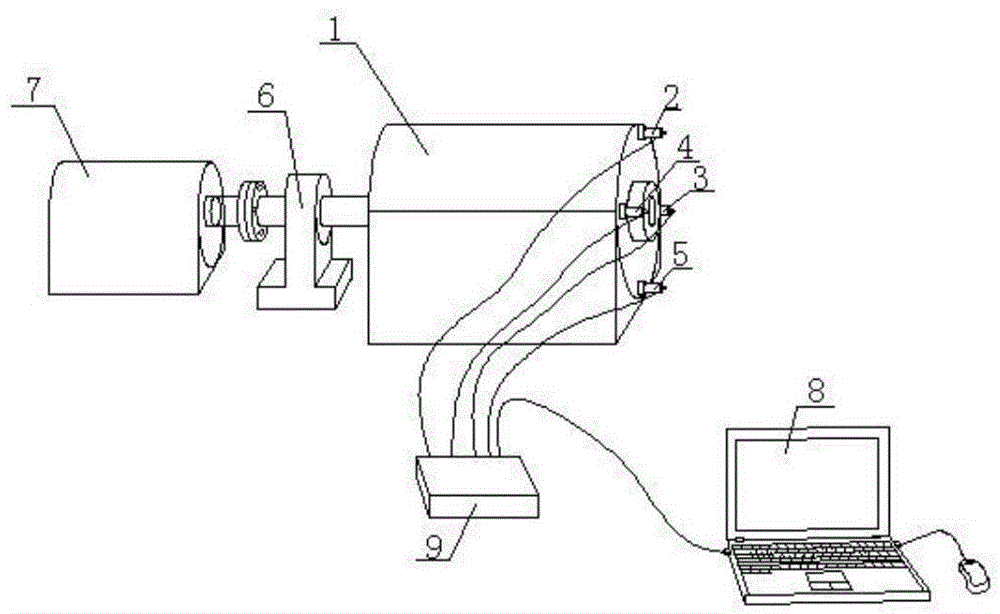

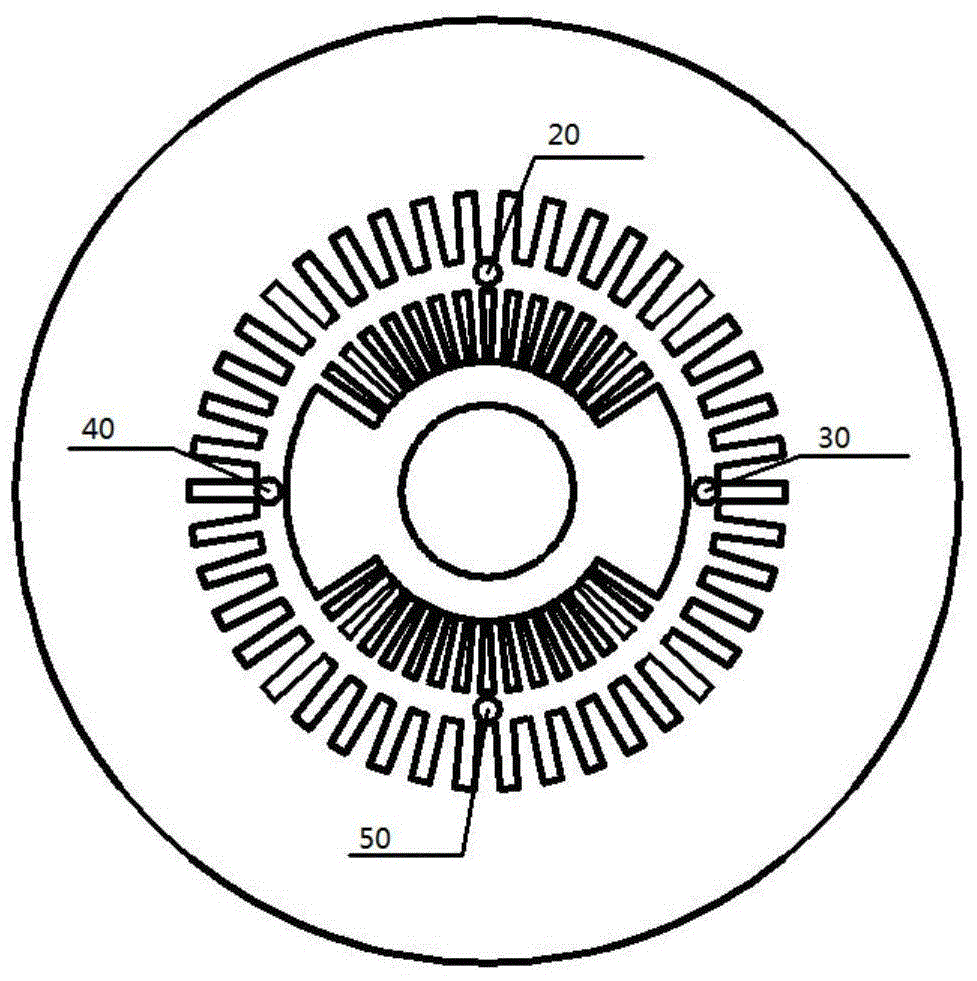

[0029] refer to figure 2 , the detection method of the present invention is in traditional generator set structure (generator 1 on the bearing block 6 obtains DC current from exciter through the exciter 7 coaxial with it), in the stator iron core of generator 1 vertical and horizontal Four Hall voltage sensors 2, 3, 4, 5 connected to the induction coil are installed in the direction, and the collected signal is transmitted to the lower computer 9 through the signal transmission line. The lower computer transmits the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com