On-line production data rapid generation and management method and system

A data processing system and production data technology, applied in the general control system, control/regulation system, comprehensive factory control, etc., can solve the problems of low data accuracy, inconvenient search, not fast enough, etc., to ensure data accuracy , reduce manual recording, and avoid data loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

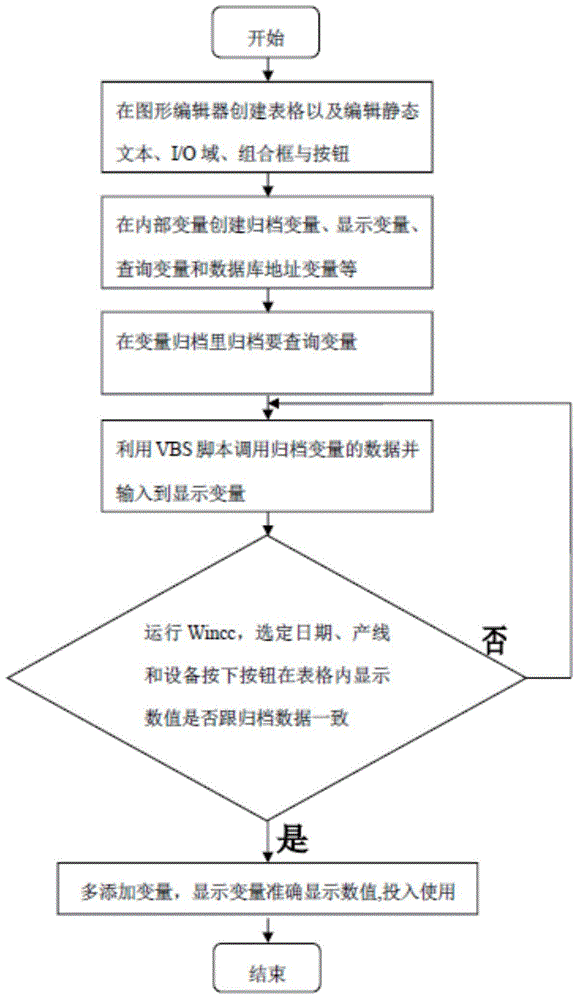

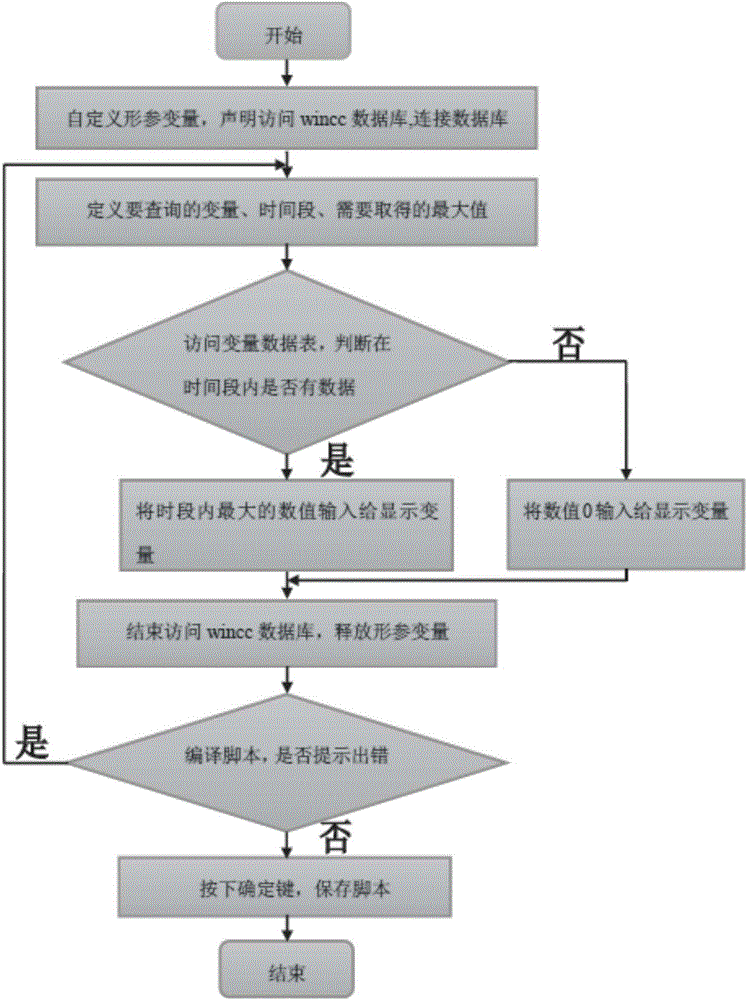

[0043] Example: see figure 1 and figure 2 , the present embodiment provides an online production data rapid generation and management method, which includes the following steps:

[0044](1) Set up an industrial computer, and connect the industrial computer with a first-level PLC controller and a second-level PLC controller connected with the first-level PLC controller, and obtain product production data through the second-level PLC controller;

[0045] (2) Set up a data processing system based on wincc architecture in the industrial computer;

[0046] (3) The data processing system creates a data table through a graphic editor, and edits static text, I / O fields, combo boxes and buttons into the created data table;

[0047] The static text is the description of the combo box and the I / O field, such as "query date", "query production line", "day shift", etc.; the I / O field is configured to display variables, and the I / O fields all display 0 values , the "year, month, day" at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com