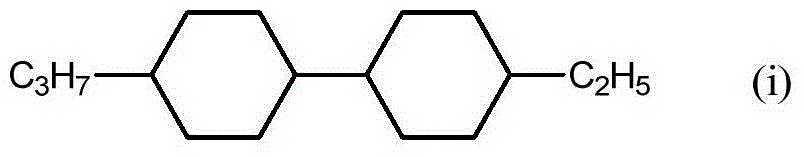

Liquid crystal composition and liquid crystal display element using same

A liquid crystal composition and compound technology, which is applied in liquid crystal materials, chemical instruments and methods, optics, etc., can solve the problems of screen burn-in, difficulty in screen burn-in, and insufficient drop mark effect, etc., and achieve less screen burn-in and high-speed Excellent responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0638] Hereinafter, the present invention will be described in more detail by citing examples, but the present invention is not limited to these examples. In addition, "%" in the composition of a following Example and a comparative example means "mass %".

[0639] The characteristics measured in the examples are as follows.

[0640] T NI : Nematic-isotropic liquid phase transition temperature (°C)

[0641] Δn: Refractive index anisotropy at 20°C

[0642] Δε: Dielectric constant anisotropy at 20°C

[0643] η: Viscosity at 20°C (mPa·s)

[0644] gamma 1 : Rotational viscosity at 20°C (mPa·s)

[0645] VHR: Under the conditions of frequency 60Hz and applied voltage 5V, the voltage retention rate at 50°C (%)

[0646] VHR after heat resistance test: The TEG for VHR measurement (test element group) injected with the liquid crystal composition was kept in a constant temperature chamber at 135° C. for 45 minutes, and then measured under the same conditions as the above-mentioned ...

Embodiment 1

[0695] Compared with the liquid crystal composition of Comparative Example 1, the liquid crystal composition LC-1 of Example 1 has lower viscosity η and rotational viscosity γ1, and is superior in various display panel evaluation performance, process suitability, and solubility at low temperature.

Embodiment 2~4

[0697] Liquid crystal compositions (LC-2 to 4) having the compositions shown below were prepared, and their physical property values were measured. In addition, using a liquid crystal display element, evaluations of burn-in, drop marks, process suitability, and solubility at low temperatures were performed. The results are shown below.

[0698] [Table 2]

[0699]

[0700] Liquid crystal compositions LC-2 to 4 of Examples 2 to 4 were found to have low viscosity η and rotational viscosity γ1, and were excellent in various display panel evaluation performance, process suitability, and solubility at low temperatures.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com