A Method for Optical Axis Fixing of Cylindrical Mirror

A cylindrical mirror and optical technology, used in turning equipment, measuring/indicating equipment, auxiliary devices, etc., can solve the problems of scratching the optical axis reference accuracy of optical components, and achieve the effect of ensuring coincidence accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

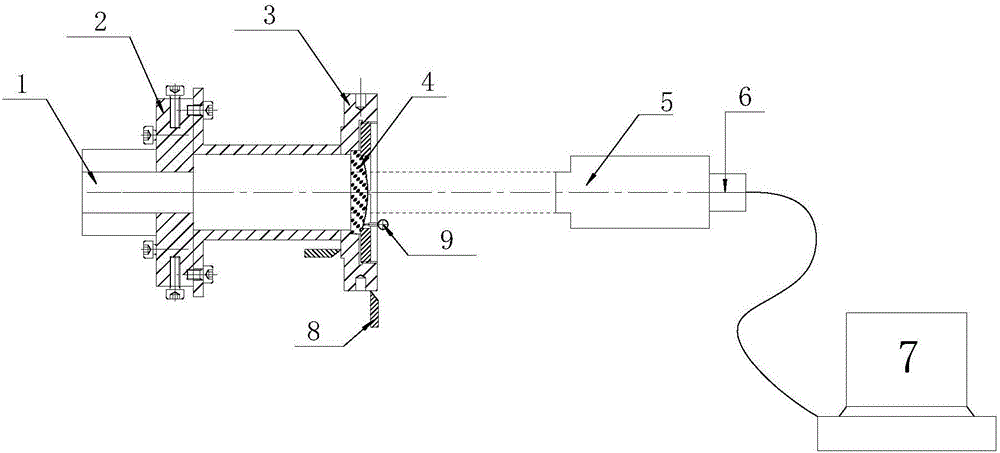

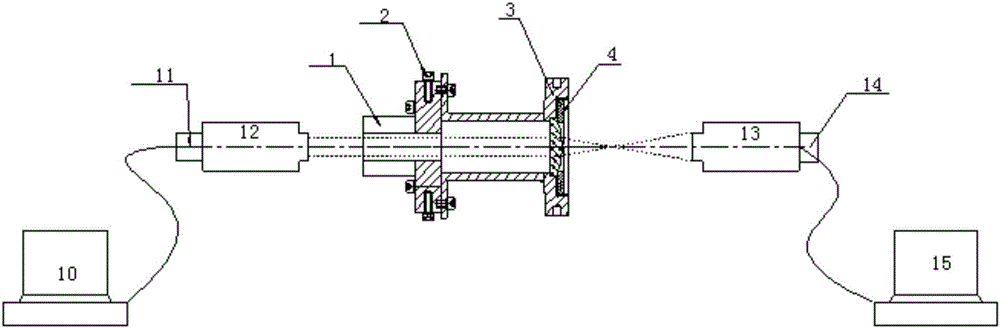

[0026] like figure 1 The cylindrical mirror optical axis fixing system shown includes attitude adjustment tooling 2, mirror frame 3, first optical centering device 12, second optical centering device 13, first CCD camera 11, second CCD camera 14, first PC 10 and the second PC 15;

[0027] The attitude adjustment tool is fixed on the rotation axis 1 of the lathe, the mirror frame is fixed on the attitude adjustment tool, and a cylindrical mirror is fixed inside the mirror frame. The first optical centering device is located at one end of the rotation axis of the lathe and faces the plane of the cylindrical mirror. The centering device is connected to one end of the first CCD camera, and the other end of the first CCD camera is connected to the first PC; the second optical centering device is located directly in front of the exit window of the frame, and the second optical centering device faces the cylindrical surface The cylindrical surface of the mirror, the second optical c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com