Double-impeller type freezing and deburring machine

A technology of sharpening machine and double impeller, applied in the direction of impeller, rotor blade, abrasive jet machine tool, etc., can solve the problems of limited launch angle, poor effect of removing sharpening, rough edge of workpiece, burr that cannot be removed, etc., and achieves a wide angle. , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

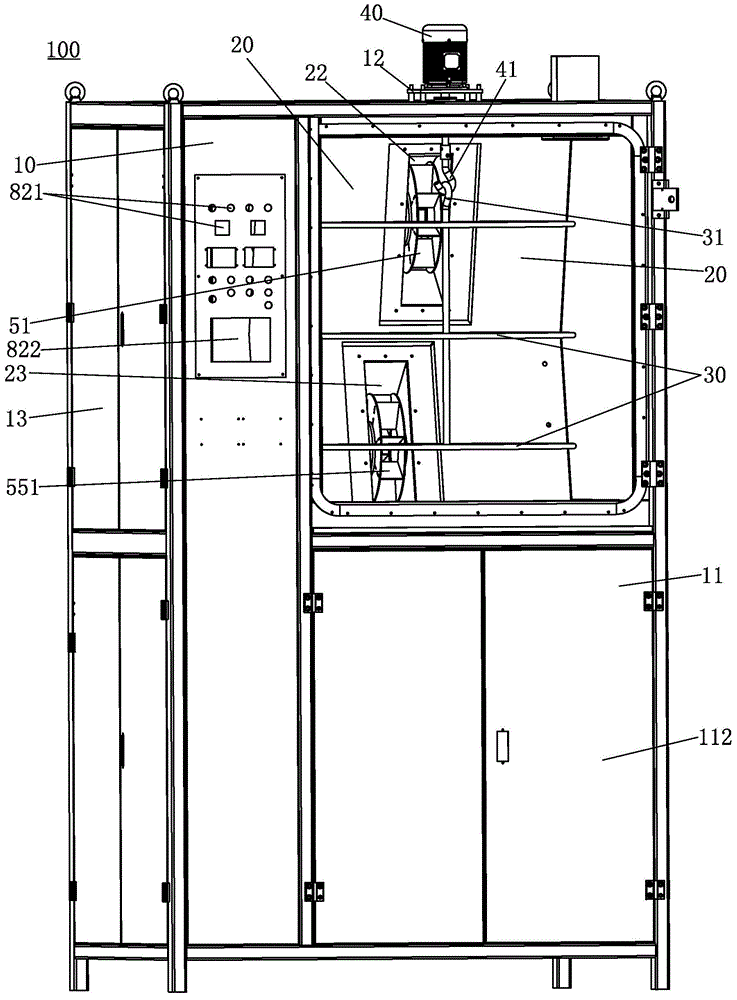

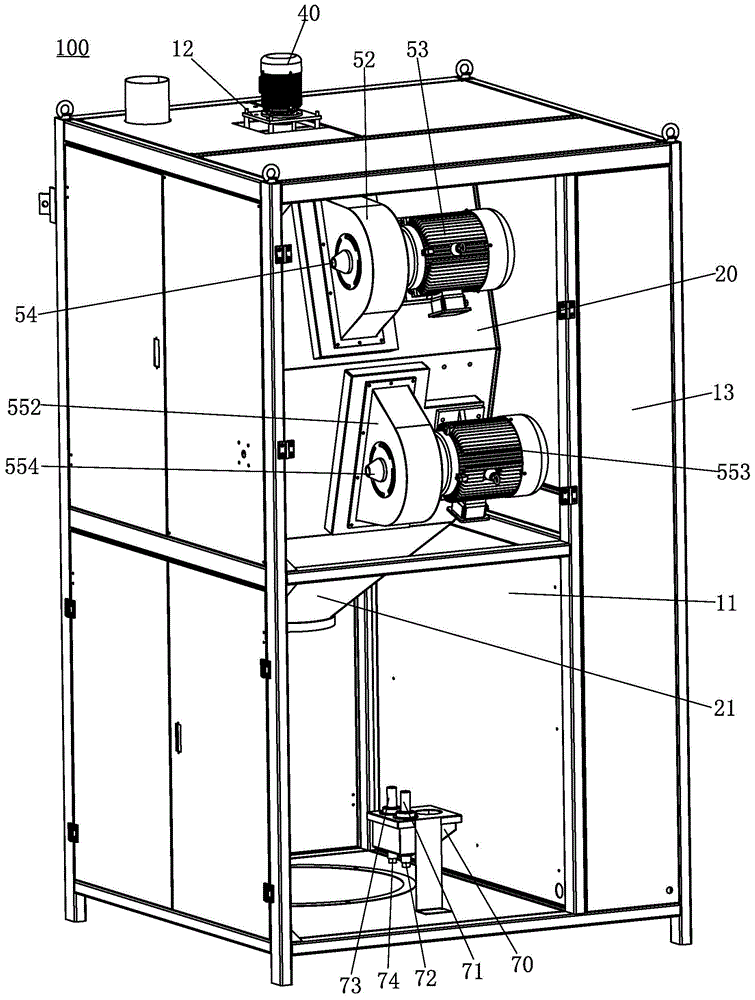

[0014] refer to figure 1 and figure 2 , the double-impeller freezer 100 of the present invention includes a cabinet 10, a freezer 20, a rotating material frame 30, a rotating motor 40, an upper impeller assembly, a lower impeller assembly, a vibrating screen (not shown), a collection box 70 and Control System. The collecting box 70 is provided with a first input end 71 , a first output end 72 , a second input end 73 and a second output end 74 .

[0015] The cabinet 10 includes a freezer-removed front machine sub-box 11 and a control box 13 located at one side of the freezer-removed front-end machine box 11 . The freezer box 20 is fixedly placed on the top of the freezer box 11 . The bottom of the freezer 20 is provided with an output funnel 21 . The front end of the freezer-removing front machine sub-box 11 is provided with an upper airtight door (not shown) and a lower airtight door 112 located below the upper airtight door. The inner wall of the freezer 20 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com