Light emitting device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

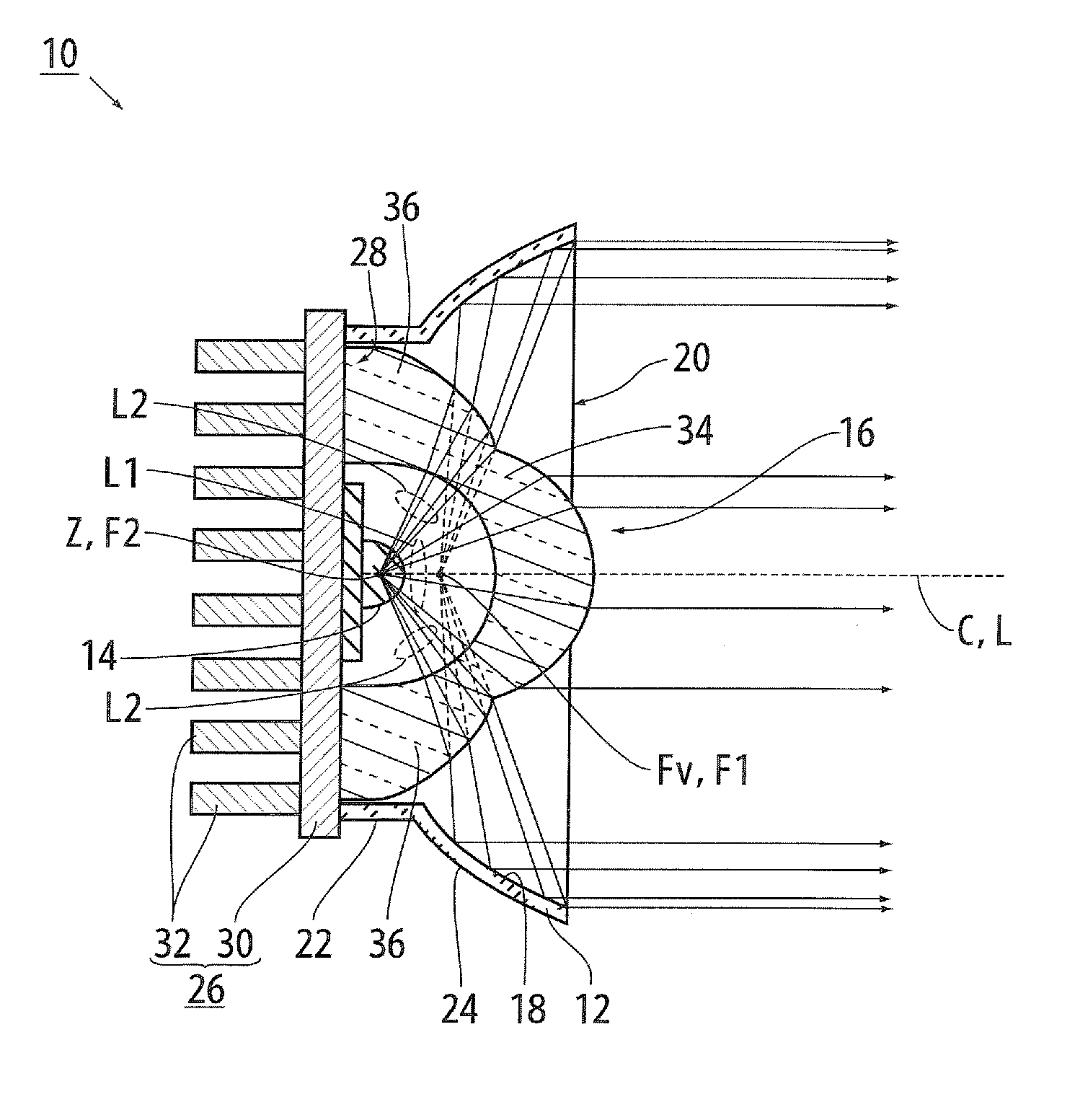

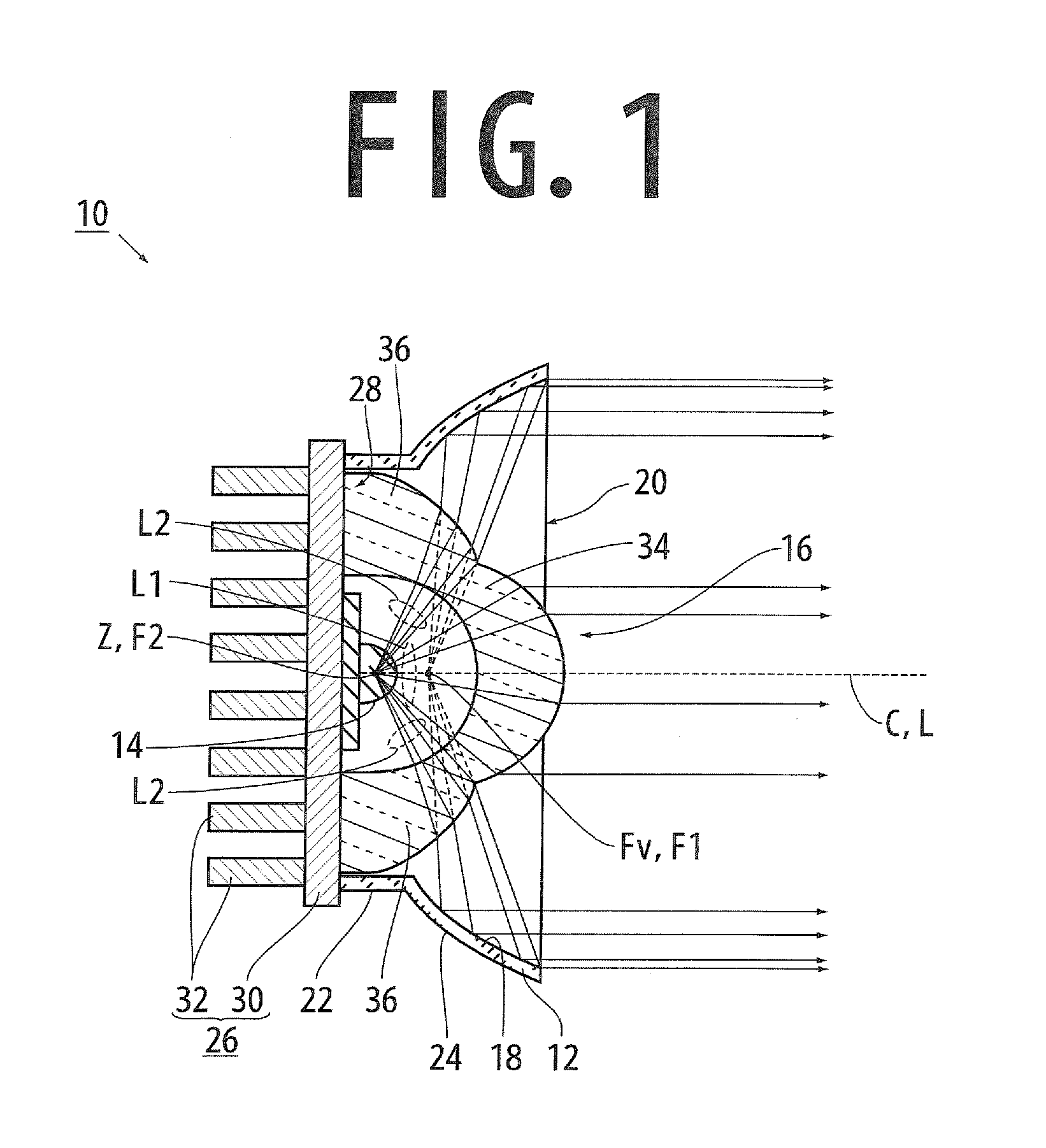

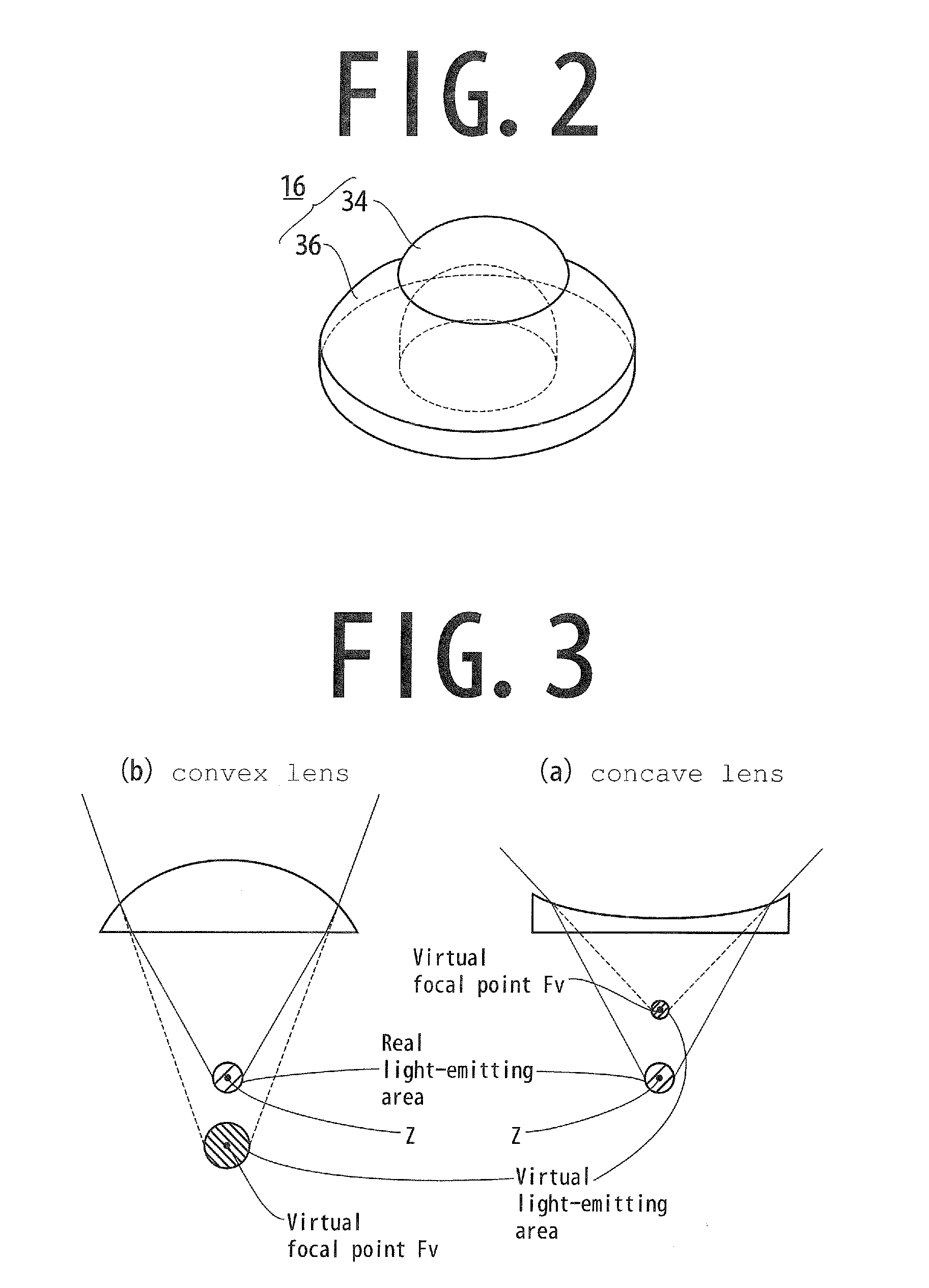

[0050]A light emitting device 10 according to the present invention is explained with figures as below. The light emitting device 10 comprises: a reflector 12, a heat sink 26 for absorption and radiation of heat, a point light source 14, and a combined lens 16.

[0051]The reflector 12 has a concave reflecting surface 18 formed inside, a light-emitting opening 20 through which light from the point light source 14 is emitted, and an almost cylindrical center cylindrical part 22 provided on the bottom-center of the concave reflecting surface 18 and facing the light-emitting opening 20. A center axis C for the reflector 12 and the concave reflecting surface 18 is a line passing through the center of the reflector 12 and being perpendicular to the light-emitting opening 20.

[0052]The reflector 12 is made of glass or aluminum, for example. The reflector 12, which is made of aluminum, has the concave reflecting surface 18 made by metal evaporation. The reflector 12, which is made of glass, ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com