Electric-heating press machine of plastic drainage plate

A plastic drainage board and pressing machine technology, applied in the field of energy conversion, can solve the problems of complex supporting facilities, large space occupation, oil and gas pollution, etc., and achieve direct and simple heating methods, high energy utilization rate, uniform and controllable temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

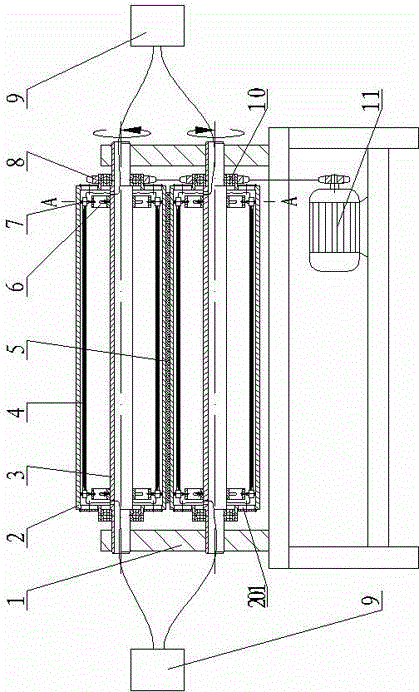

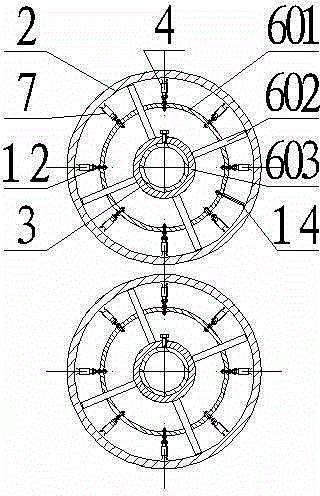

[0013] The present invention will be further described below in conjunction with accompanying drawing:

[0014] as attached figure 1 , 2 As shown, the pressing roller 2 is movably connected to the pressing roller main shaft 3 through the bearing 10; The two supporting rims 6 fixedly installed on the main shaft 3 of the pressing roller, and the clips 7 connected to the rims of the two supporting rims 6 through adjusting bolts 12, are in a form parallel to the axis of the main shaft 3 of the pressing roller , evenly distributed and clamped on the rim of the support rim 6, the parallel distance between it and the inner wall of the pressing roller 2 can be adjusted by adjusting the bolt 12; the electric heating tube 4 is an infrared heating tube, and its temperature can be adjusted by the temperature controller 9 control.

[0015] When the present invention works, start the reducer 11, and the power drives the sprocket 8 through the chain to make the upper and lower two pressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com