Shaped drug application station

A special-shaped drug and pharmaceutical engineering technology, which is applied in the direction of transportation, packaging, storage devices, etc., can solve the problems of affecting the work efficiency of pharmacists and increasing the risk of operation, so as to achieve the effect of safe and reliable drug feeding process and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific drawings and embodiments.

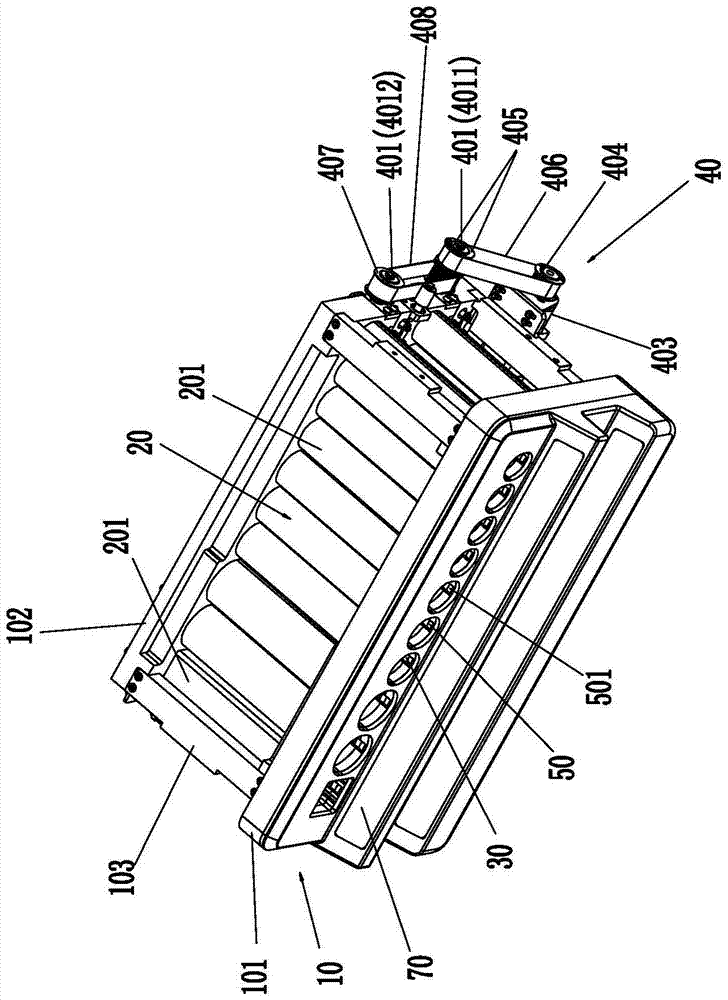

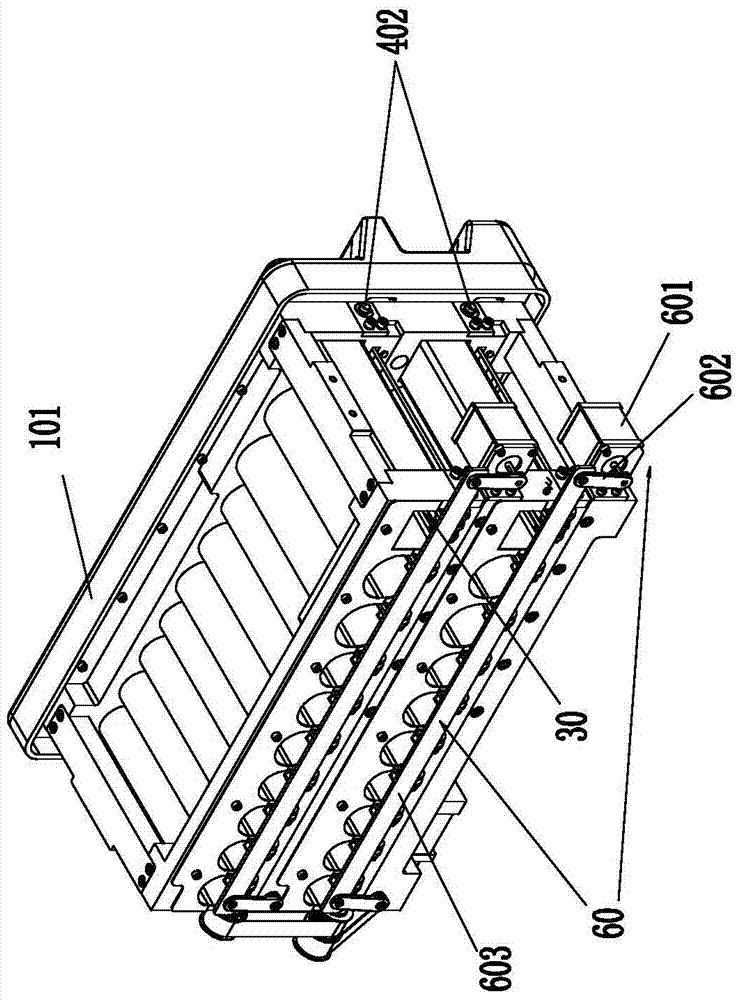

[0027] The special-shaped drug feeding station provided by the invention, such as figure 1 and figure 2 as shown,

[0028] It includes a station frame assembly 10 , a drug loading channel assembly 20 , a conveyor belt 30 , a drug feeding transmission mechanism 40 , a counting assembly 50 , a drug blocking plate assembly 60 , and a display panel 70 .

[0029] The station frame assembly 10 includes a front frame 101 of the drug feeding channel and a rear frame 102 of the drug feeding channel; the front frame 101 of the drug feeding channel and the rear frame 102 of the drug feeding channel are connected and fixed as a whole through a support member 103;

[0030] In this embodiment, the two-layer drug feeding channel assembly 20 is installed on the station frame assembly 10, and each drug feeding channel assembly 20 includes a plurality of drug feeding channels...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com