Corrosion-resistant protein enamel pot and application

An enamel jar, protein technology, applied in the fields of peptides, organic chemistry, chemical instruments and methods, etc., can solve the problems that cannot meet the acidic liquid distillation, single function and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

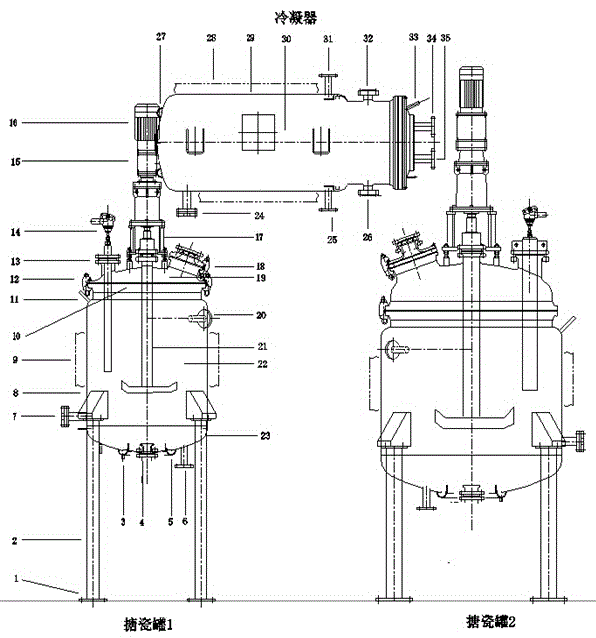

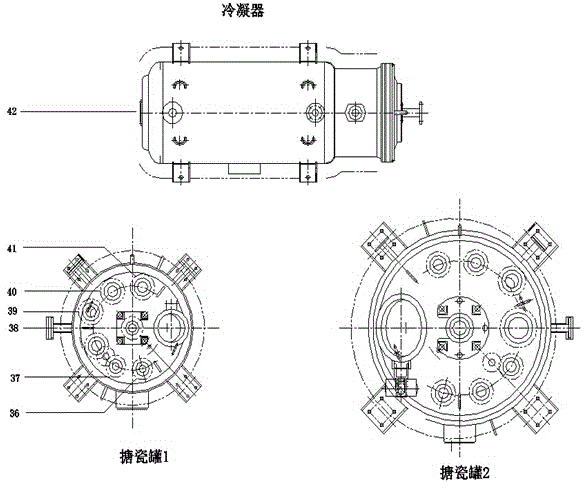

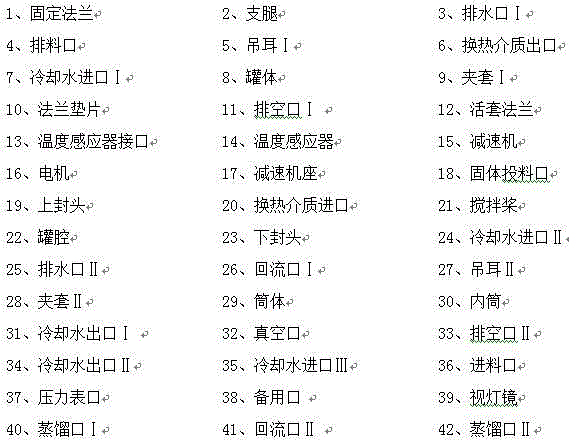

[0078] figure 1 It is a schematic cross-sectional structure diagram of the present invention; figure 2 It is a schematic diagram of the top view structure.

[0079] A corrosion-resistant protein enamel tank is characterized in that it includes an enamel tank 1, a condenser and an enamel tank 2. The enamelled tanks can be used for reactions and distillations; where the

[0080] The condenser includes a jacket II28, a cylinder body 29, and an inner cylinder 30, which is the cooling unit of the equipment, and is used for cooling and recovering steam in the reaction and distillation process; the jacket II28 includes a cooling water inlet II24, a drain outlet II25, a cooling water Outlet I31, emptying port II33, lifting lug II27; the cooling water inlet II24 is at the lower part of the jacket II28 in the vertical direction, and the cooling water outlet I31 is at the upper part of the jacket II28 in the vertical direction, distributed diagonally; The cylinder body 29 include...

Embodiment 2

[0084] Such as figure 1 As shown, a corrosion-resistant protein enamel tank includes an enamel tank 1, a condenser and an enamel tank 2.

[0085] Such as figure 1 and figure 2 As shown, the condenser includes a jacket II, a cylinder, and an inner cylinder; the jacket II includes a cooling water inlet II, a drain outlet II, a cooling water outlet I, an emptying port II, and a lifting lug II; the cooling water inlet II is at the lower part of the jacket II in the vertical direction, and the cooling water outlet I is at the upper part of the jacket II in the vertical direction; the cylinder includes a vacuum port, a return port I, and a distillation port II, and the cylinder body and the vacuum port and return port I , The distillation port II is connected; the inner cylinder includes cooling water inlet III and cooling water outlet II, and the cooling water inlet II and cooling water outlet I are connected to the cylinder body. The inner surface of the cylinder is sprayed wi...

Embodiment 3

[0091] Adopt the method for hydrolyzing protein of corrosion-resistant protein enamel tank of the present invention:

[0092] (1) Feeding: Vacuum suction the required amount of hydrochloric acid into the cavity of enamel tank 1 through the feed inlet, and put the required amount of protein solid into the cavity of enamel tank 1 through the solid feeding port.

[0093] (2) Stirring of materials: Turn on the stirring, and mix the materials evenly through stirring;

[0094] (3) Material reaction: Industrial steam passes through the enamel tank 1 jacket Ⅰ to heat the material to 118°C and react for 72 hours;

[0095] (4) Distillation of materials under reduced pressure: Turn on the low-temperature cooling water of the condenser and the enamel tank 2, control the temperature at 60°C, and carry out vacuum distillation at -0.07MPa;

[0096] (5) The material is filtered by activated carbon: dissolve 7.5% activated carbon in the material, suck it into the tank through the material inl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com