Flame retardant smoke suppressant and pvc flame retardant smoke suppressant polymer for cables

A flame-retardant smoke suppressant and polymer technology, which is applied in the field of flame-retardant smoke suppressant and PVC flame-retardant smoke suppressant polymer for cables, can solve the problems of high price, increased toxicity index, and poor flame-retardant effect, and achieves Low price, strong smoke elimination ability, good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

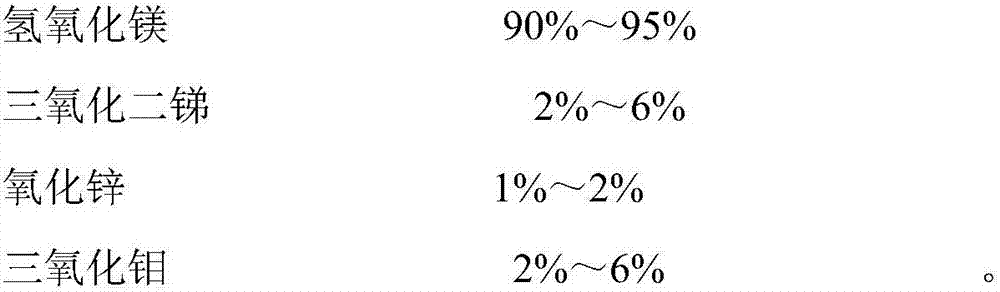

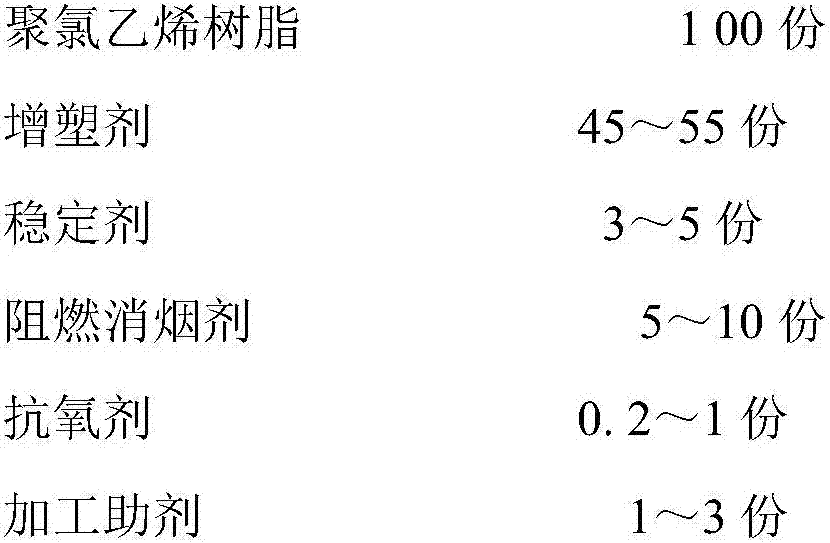

[0057] Preparation of Flame Retardant Smoke Suppressant

[0058] Commercially available natural brucite with magnesium hydroxide content ≥ 96% is mechanically crushed into 325-mesh magnesium hydroxide powder, crushed in a supersonic fluidized bed jet mill, and classified by a three-stage cyclone to obtain an average particle size of 0.5- 0.85μm submicron micropowder, add a coupling agent (see Table 1) corresponding to the weight of magnesium hydroxide. Put it into a 900 rpm high-speed mechanical mixer, mix until the temperature reaches 120-130 ° C, stop high-speed stirring and discharge, put it into a high-pressure fluidized bed jet mill after cooling down, and undergo secondary treatment at 2000 rpm. The obtained activated magnesium hydroxide has good slipperiness, and flows in waves when pushed in a flat plate, and no obvious agglomerated particles are found by microscope observation. Then add the corresponding antimony trioxide, zinc oxide, and molybdenum trioxide (see Tab...

Embodiment 2

[0062] Preparation of Flame Retardant Smoke Suppressant

[0063] Commercially available natural brucite with magnesium hydroxide content ≥ 96% is mechanically crushed into 325-mesh magnesium hydroxide powder, crushed in a supersonic fluidized bed jet mill, and classified by a three-stage cyclone to obtain an average particle size of 0.85~ 1μm submicron micropowder, add the corresponding percentage of the weight of magnesium hydroxide coupling agent (see Table 1). Put it into a 900 rpm high-speed mechanical mixer, mix until the temperature reaches 120-130 ° C, stop high-speed stirring and discharge, put it into a high-pressure fluidized bed jet mill after cooling down, and undergo secondary treatment at 2000 rpm. The obtained activated magnesium hydroxide has good slipperiness, and flows in waves when pushed in a flat plate, and no obvious agglomerated particles are found by microscope observation. Then add the corresponding antimony trioxide, zinc oxide, and molybdenum trioxi...

Embodiment 3

[0067] Preparation of Flame Retardant Smoke Suppressant

[0068] Commercially available natural brucite with magnesium hydroxide content ≥ 96% is mechanically crushed into 325-mesh magnesium hydroxide powder, crushed in a supersonic fluidized bed jet mill, and classified by a three-stage cyclone to obtain an average particle size of 0.5- 0.7μm submicron micropowder, add a coupling agent with a weight corresponding to the percentage of magnesium hydroxide (see Table 1). Put it into a 900 rpm high-speed mechanical mixer, mix until the temperature reaches 120-130 ° C, stop high-speed stirring and discharge, put it into a high-pressure fluidized bed jet mill after cooling down, and undergo secondary treatment at 2000 rpm. The obtained activated magnesium hydroxide has good slipperiness, and flows in waves when pushed in a flat plate, and no obvious agglomerated particles are found by microscope observation. Then add the corresponding antimony trioxide, zinc oxide, and molybdenum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com