A Template Sewing Machine with Electromagnetic Tension Adjuster

A tension adjustment and sewing machine technology, applied in the field of template sewing machines, can solve problems such as loss, inconvenient adjustment, defectiveness, etc., and achieve the effects of ensuring stability, reducing labor costs, and reducing the probability of emergencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

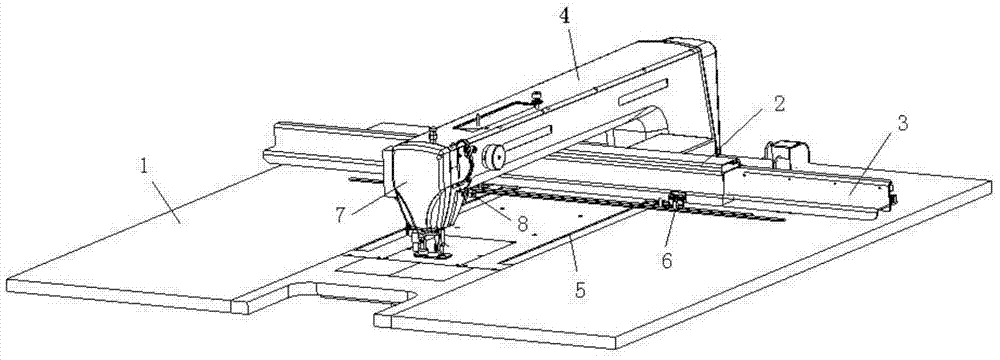

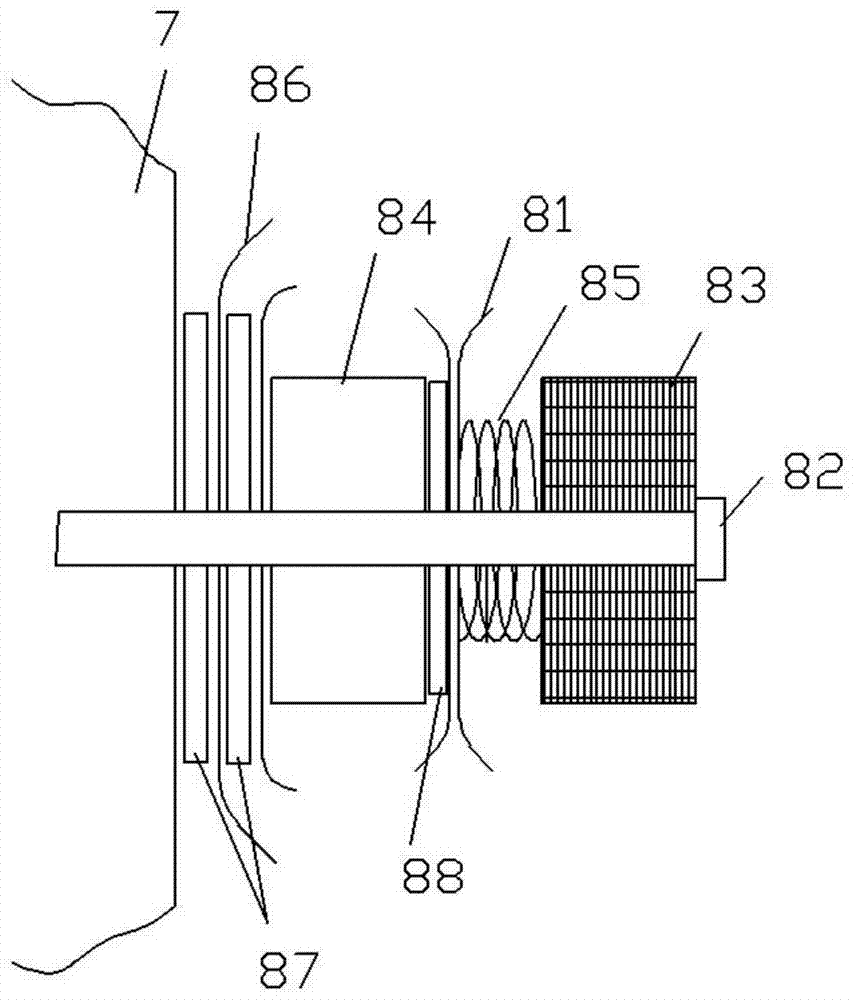

[0016] Such as figure 1 with figure 2 As shown, a template sewing machine with an electromagnetic tension adjuster includes a station platform 1, a frame 4, a machine head 7, a splint 6, a longitudinal groove 5, a moving beam 3 and a sliding block 2, and the frame 4 is installed on On the station platform 1, the splint 6 is set on the sliding block 2, the sliding block 2 can slide left and right along the moving beam 3, and the moving beam 3 can move back and forth on the station platform 1 along the longitudinal groove 5, its characteristic That is: an electromagnetic tension adjuster 8 is arranged on the machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com