A structure to prevent the deflection of the piston rod of the shield machine's single propulsion cylinder

A technology of piston rod and shield machine, applied in the direction of fluid pressure actuating device, etc., can solve the problem of difficult deflection of the piston rod of single propulsion cylinder, and achieve the effect of not affecting the turning performance, improving efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

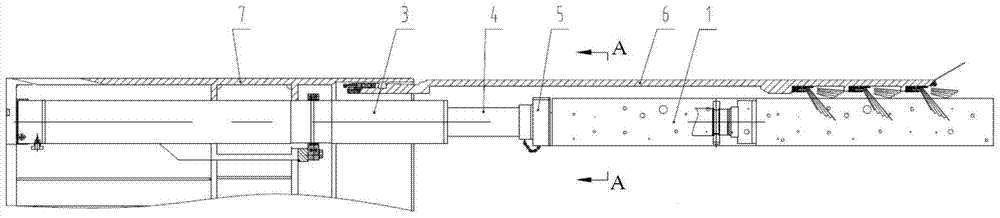

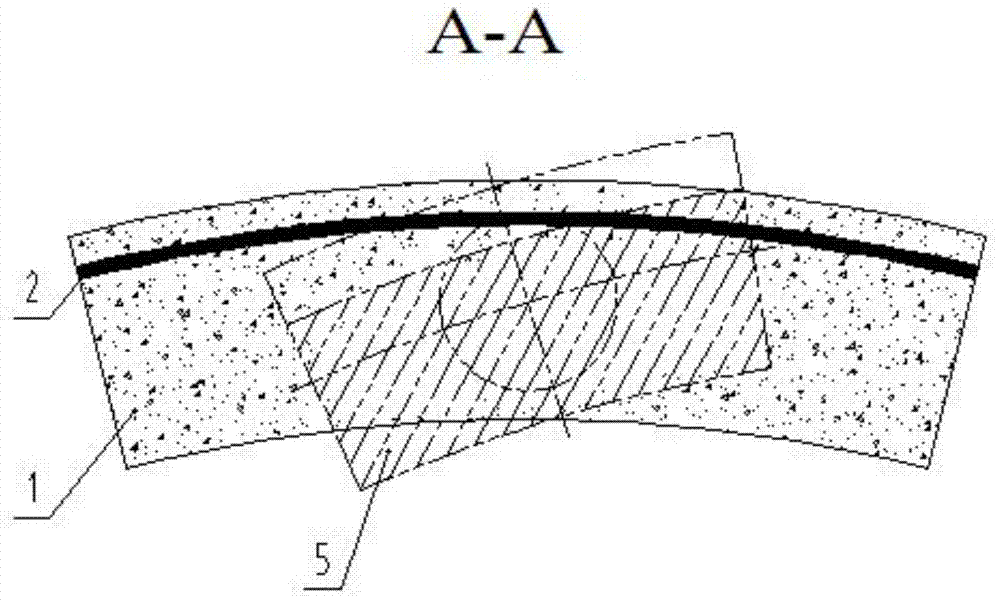

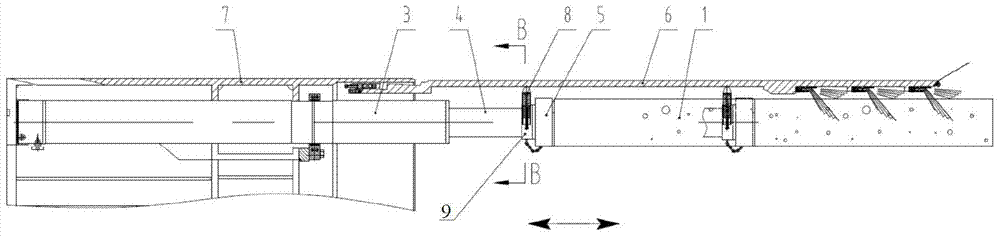

[0044] Implementation Mode 1: Please refer to Figure 3 ~ Figure 7 , adjust the relative position of the piston rod 4 and the cylinder barrel 3 of the propulsion cylinder according to the correct deflection position of the strut 5 of the single propulsion cylinder, so that the correct position of the piston rod 4 is used as the rear installation The installation datum of the frame 9 and the stay shoe 5. The mounting frame 9 is fixedly mounted on the end of the piston rod 4, and the symmetry plane of the mounting frame 9 passes through the axis of the piston rod 4 and the axis (or center of circle) of the shield tail 6. Two anti-deflection mechanisms 8 are symmetrically fixedly installed on both sides of the mounting frame 9. When installing the anti-deflection mechanism 8, it should be ensured that the support platform 86 of this mechanism is kept in contact with the inner wall of the shield tail 6 or left behind. There is a small gap. The guide sleeve 85 is installed on the...

Embodiment approach 2

[0049] Implementation Mode 2: Please refer to Figure 10 and Figure 11 , put the piston rod 4 and the brace shoe 5 in the correct position according to the same steps of the embodiment, fix the anti-bias mechanism 8 on both sides of the brace shoe 5, and install the anti-bias mechanism 8, ensure that the support platform 86 is in close contact with the inner wall of the shield tail 6 and that the elastic member 84 is compressed to a certain extent. When the shield machine turns, the working process and deviation correction principle of the anti-deviation mechanism 8 are the same as those in the first embodiment.

[0050] The technical scheme provided by the invention has the following beneficial effects:

[0051] 1. By setting the anti-deflection mechanism 8 and using the cooperation of the guide sleeve 85, the elastic member 84 and the adjustment bolt 82, the piston rod 4 can automatically return to the equilibrium position when it deflects, effectively Prevent the circum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com