External pressure rubber joint

A technology of rubber joints and external joints, applied in the direction of pipes/pipe joints/fittings, adjustable connections, passing components, etc., can solve problems such as sucking flat rubber joints, danger, mechanical damage, etc., and achieve good shock absorption and pressure reduction, The effect of increasing the service life and preventing the risk of explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

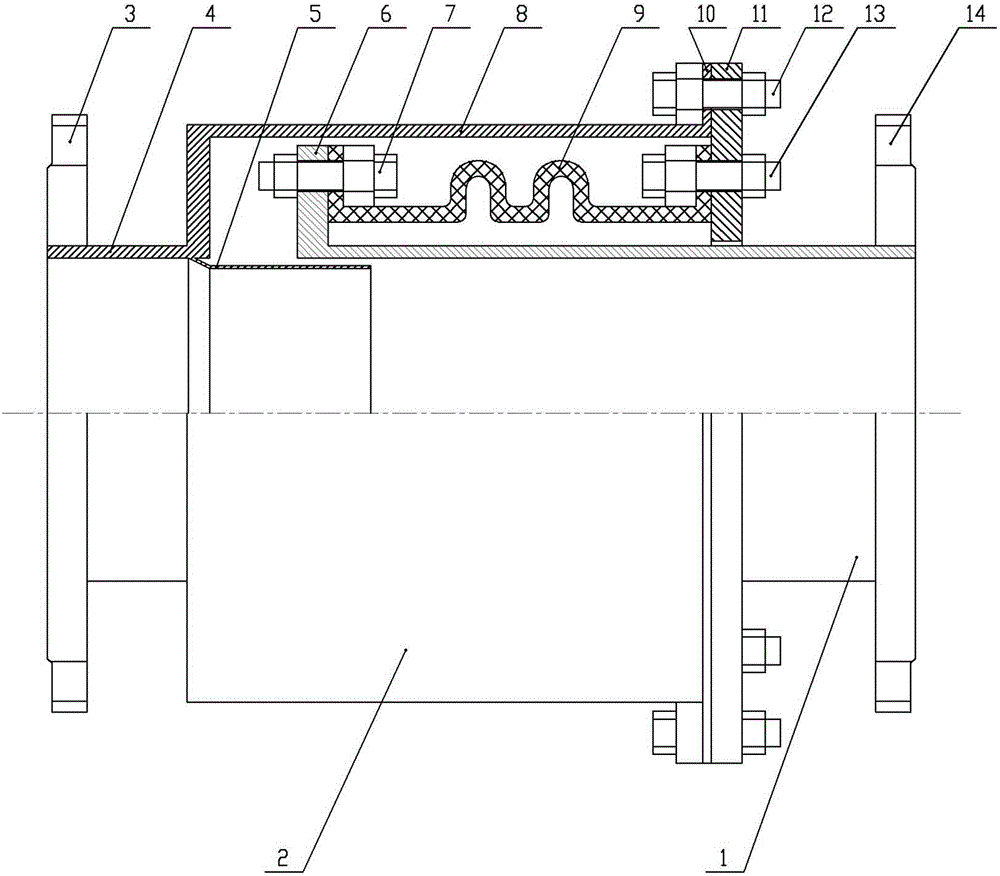

[0021] Embodiment 1: A kind of external pressure rubber joint, see figure 1 , including an outer joint 2, an inner joint 1, a connection plate 11 and a rubber compensator 9, the outer joint 2 includes an integrally formed inlet part 4 and a shell part 8, the inner diameter of the outer shell part 8 is larger than the inner diameter of the inlet part 4, and the inner diameter of the inlet part 4 A flange 3 is provided at the end of the shell part 8, and a first flange 10 is provided at the end of the outer shell part 8; the inner joint 1 includes an outlet part and a telescopic part, and the telescopic part is set in the shell part 8 of the outer joint 2, and the telescopic part A second flange 6 is provided at the end of the outlet portion, and a flange 14 is provided at the end of the outlet portion; the inner diameter of the inner joint 1 is equal to the inner diameter of the inlet portion 4 of the outer joint 2 . When using this external pressure rubber joint for pipeline c...

Embodiment 2

[0024] Embodiment 2: An external pressure rubber joint, the difference from Embodiment 1 is that the wave number of the rubber bellows used is 3.

[0025] The realization method in the above-mentioned embodiment is: the liquid flows in from the inlet part 4 of the outer joint 2, and then flows out from the outlet part of the inner joint 1. The space between the guide tube 5 and the inner wall of the inner joint 1, and the space between the second flange 6 of the inner joint 1 and the inner wall of the outer joint 2 are filled in the space between the rubber compensator 9 and the outer joint 2, such as figure 1 As shown, this part of the liquid generates pressure on the rubber compensator 9. When the internal pressure of the joint increases, the rubber compensator 9 deforms and elongates under the action of external pressure, reducing the impact and pressure, thereby effectively dispersing the internal pressure of the joint , which limits the expansion limit of the rubber joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com