A method for encapsulating flat membrane elements used in membrane aerated biofilm reactors

A technology of membrane aeration biofilm and encapsulation method, which is applied in the field of encapsulation of flat membrane elements, can solve the problems of unsuitable sealing, low adhesive strength, and poor adhesion, and achieve the effect of ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

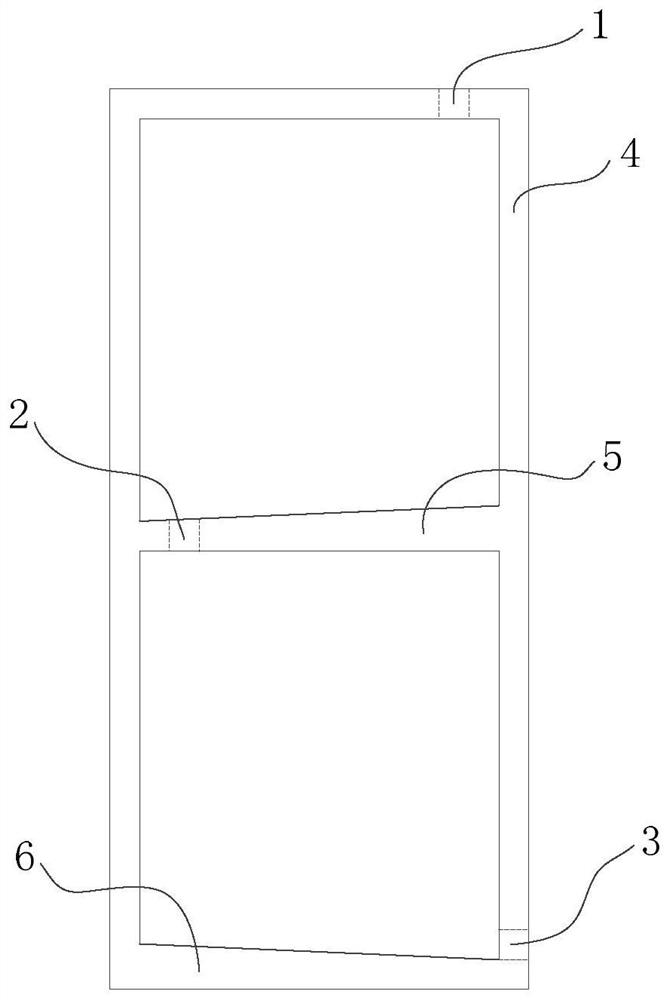

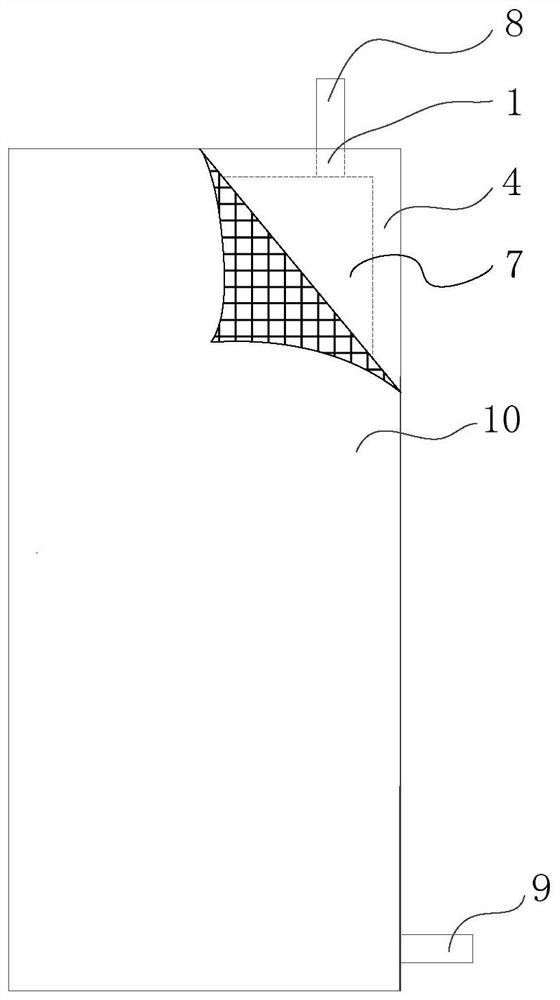

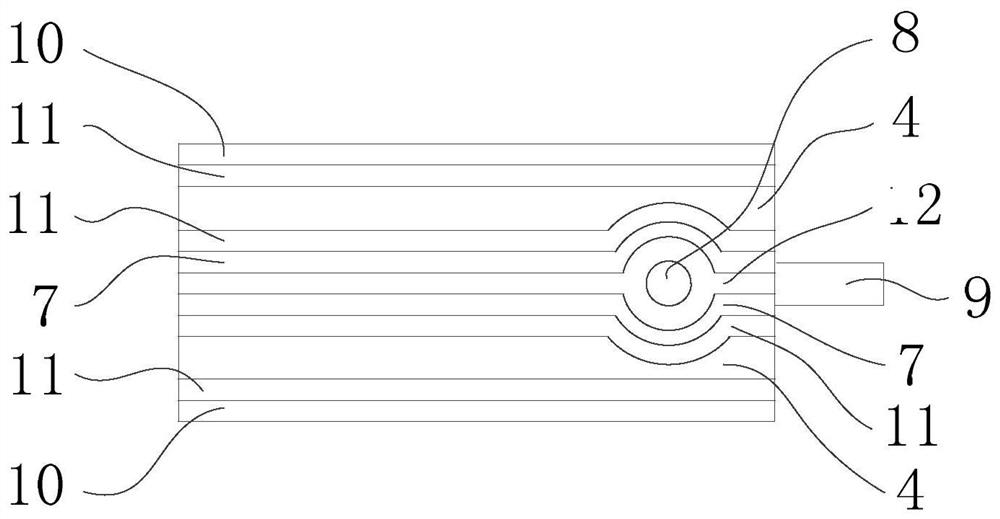

[0047] Prepare a pair of frames including the support frame and the beam in the frame. The beam in the frame has no slope. Reserve semi-circular grooves at the support frame and the beam in the frame, so that they can be aligned and spliced to form air inlets and drains. and through holes. Apply a uniform layer of encapsulant on the grooved side of the frame (A1:B1 is 1:0.6 by volume), and cut a silicone rubber film with a thickness of 100 μm to a size slightly larger than the frame, paste it on the coated On the surface of one side of the frame of the encapsulant, apply a slight force to make the silicone rubber film adhere to the frame, and naturally cure in the air for 8 hours at room temperature.

[0048] Take a frame with a silicone rubber film that has been cured in the above steps, and evenly coat the encapsulant two (A2:B2 with a volume ratio of 1:1) on the frame with the silicone rubber film on the other side of the silicone rubber film. around the side, and place ...

Embodiment 2

[0053] Prepare a pair of frames including the support frame and the beam in the frame. The beam in the frame has no slope. Reserve semi-circular grooves at the support frame and the beam in the frame, so that they can be aligned and spliced to form air inlets and drains. and through holes. Apply a uniform layer of encapsulant on the grooved side of the frame (A1:B1 is 1:0.6 by volume), and cut a silicone rubber film with a thickness of 100 μm to a size slightly larger than the frame, paste it on the coated On the surface of one side of the frame of the encapsulant, apply a slight force to make the silicone rubber film adhere to the frame, and naturally cure in the air for 8 hours at room temperature.

[0054] Take a frame with a silicone rubber film that has been cured in the above steps, and evenly coat the encapsulant two (A2:B2 is 1:1 by volume) on the frame with the silicone rubber film on the other side of the silicone rubber film. around the side, and place a silicone...

Embodiment 3

[0060] The difference from Example 2 is that the semi-finished product of the flat membrane element is covered with a non-woven fabric (specification is 30g / m2). 2 ) is hydrophobic, covered and pasted on the two sides of the semi-finished flat membrane element, and cured in the air for 8 hours at room temperature to complete the encapsulation of the flat membrane element.

[0061] The packaged flat membrane element is 15cm long, 7cm wide and 0.8cm thick, and the effective membrane surface area is 162cm 2 . The flat membrane element was vertically placed and fixed in a cylindrical reactor with a height of 22 cm and a diameter of 8 cm along the length direction. At a water temperature of 25°C, the specific surface area of the membrane is 16.2m 2 / m 3 , using an air compressor to supply air, the aeration pressure of the flat membrane element is 3kPa, 4kPa and 6kPa respectively, and under the condition of no hydraulic disturbance, according to the urban construction industry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com