High-efficiency LED double-chip high beam and low beam integrated automobile headlamp optical system

An LED light source, dual-chip technology, applied in the field of automotive lighting, can solve the problems of bright spots, poor lighting effect, uneven light, etc., and achieve the effects of improving energy efficiency, improving light output, and improving brightness and light efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

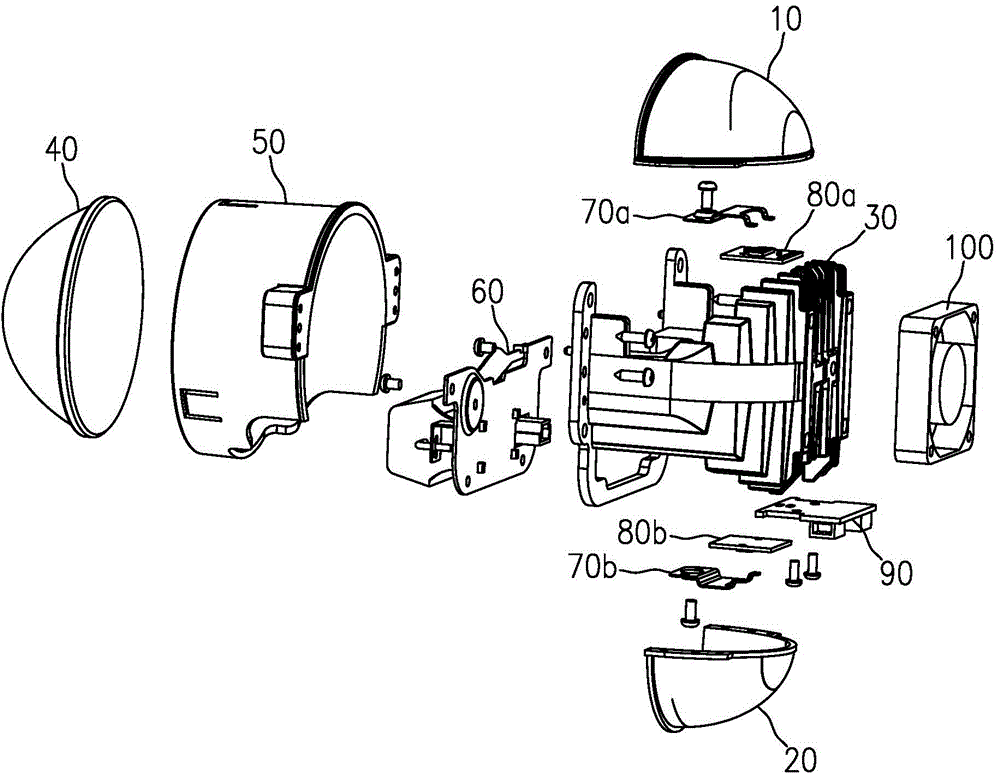

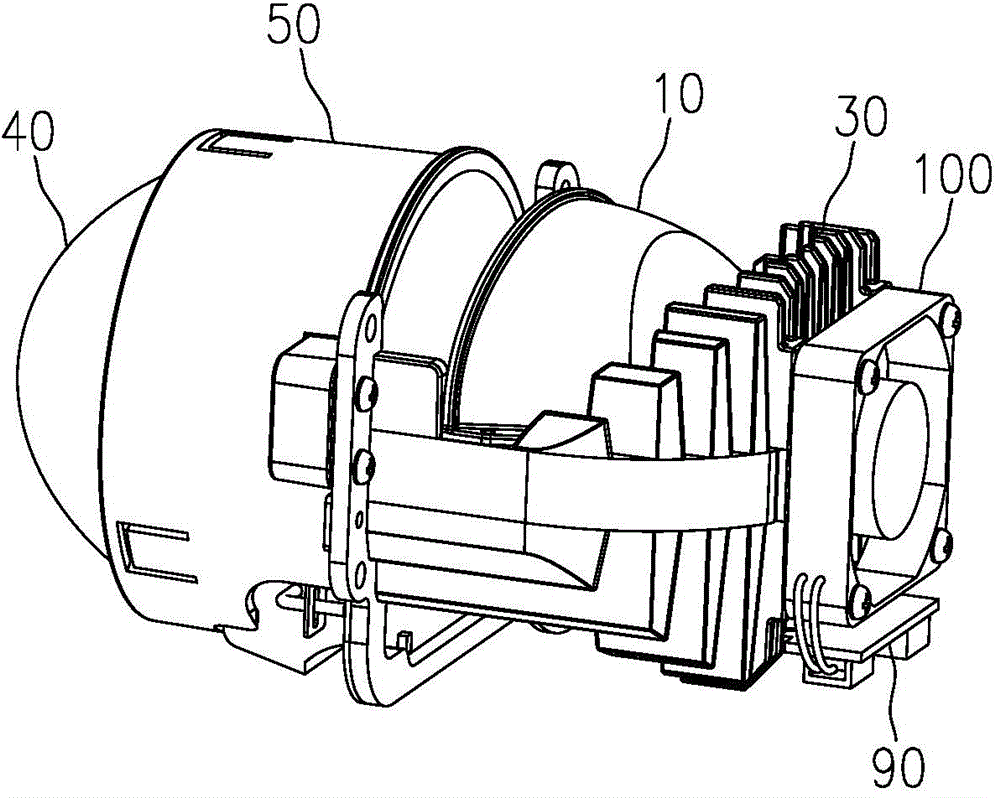

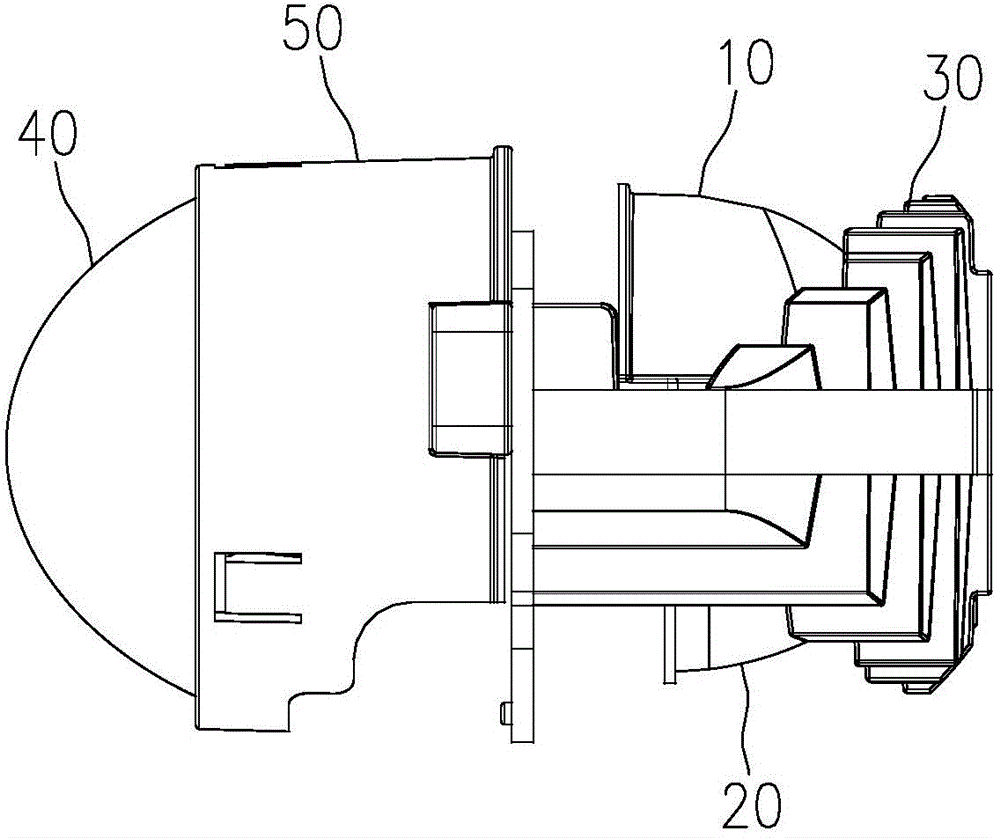

[0064] For ease of understanding, the specific structure of each component in the automobile headlight module will be further described below in conjunction with the accompanying drawings.

[0065] 1. Lens

[0066] Such as Figure 5 , 6 As shown, the lens 40 is a plano-convex lens, including a planar incident surface 42 and an outer convex surface 41 for light output; the lens 40 is provided with a positioning convex ring 43 protruding outside the outer convex surface 41 on a side close to the incident surface 42 , the rotation axes of the convex surface 41 and the positioning convex ring 43 coincide with each other; there is a transparent mirror body between the incident surface and the convex surface for light emission.

[0067] The lens 40 is made of high borosilicate optical grade glass.

[0068] Such as Image 6 As shown, the thickness of the outer convex surface 41 of the lens 40 is B, the front section part whose thickness is B / 3 from the top of the outer convex sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com