A new type of side suction range hood oil filter and oil collection system

A range hood and side suction type technology, applied in the field of the new side suction type range hood oil filter and oil collection system, can solve the problems of difficult cleaning and replacement, difficult cleaning, oil pollution, etc., so as to avoid the untimely and unsmooth flow of oil droplets , Easy to replace and clean, beautiful structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Preferred embodiments of the present invention will be described in detail below with reference to the drawings.

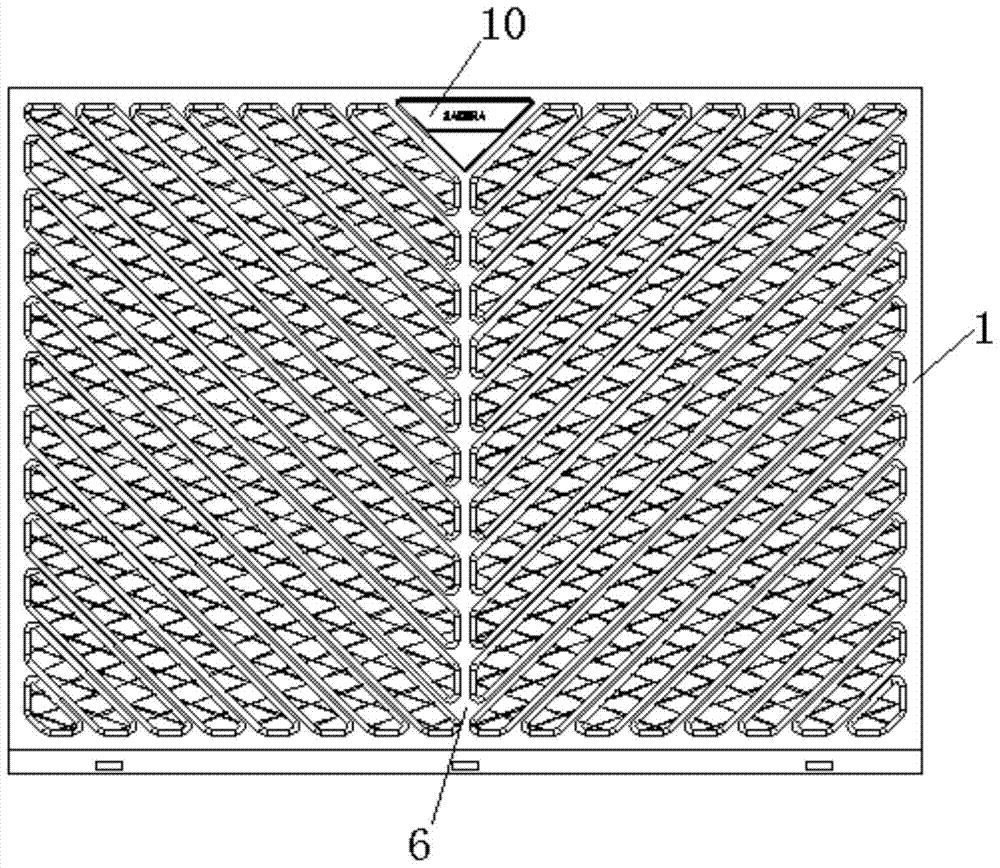

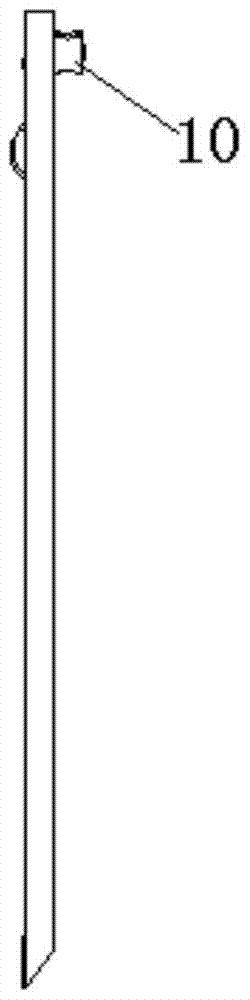

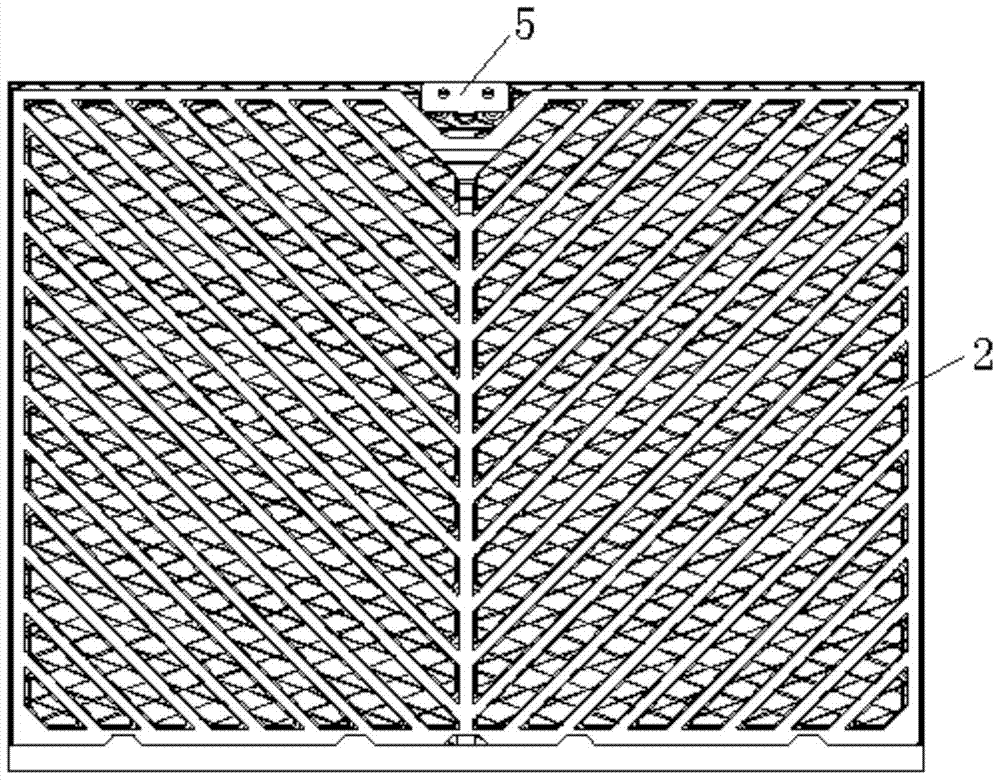

[0035] A novel side-suction range hood oil filter and oil collection system according to the present invention, the range hood includes a casing and an oil screen assembly, the middle frame of the casing is provided with an oil fume suction port, and the oil screen assembly is opposite to The horizontal plane is arranged obliquely and can just cover the oil fume suction port; the oil screen assembly includes an oil collection screen 1, a clamping screen 2 and an oil filter screen 3, and the oil collection screen 1, clamping screen 2 and filter screen The oil nets 3 are all plate-shaped structures, wherein the top of the oil collection net 1 can be magnetically adsorbed on the middle frame and is located on the outer side (ie the front side) of the vertical plane where the top edge of the oil fume suction port is located At the position, the bottom of the oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com