Oil-filled cable stop well monitoring system

An oil-filled cable and monitoring system technology, applied to measuring devices and instruments, can solve problems such as increased maintenance workload and maintenance costs, oil pressure signals cannot be sent normally, and signals cannot be sent normally, so as to achieve comprehensive and reliable detection and prevent Effect of immersion and wide distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

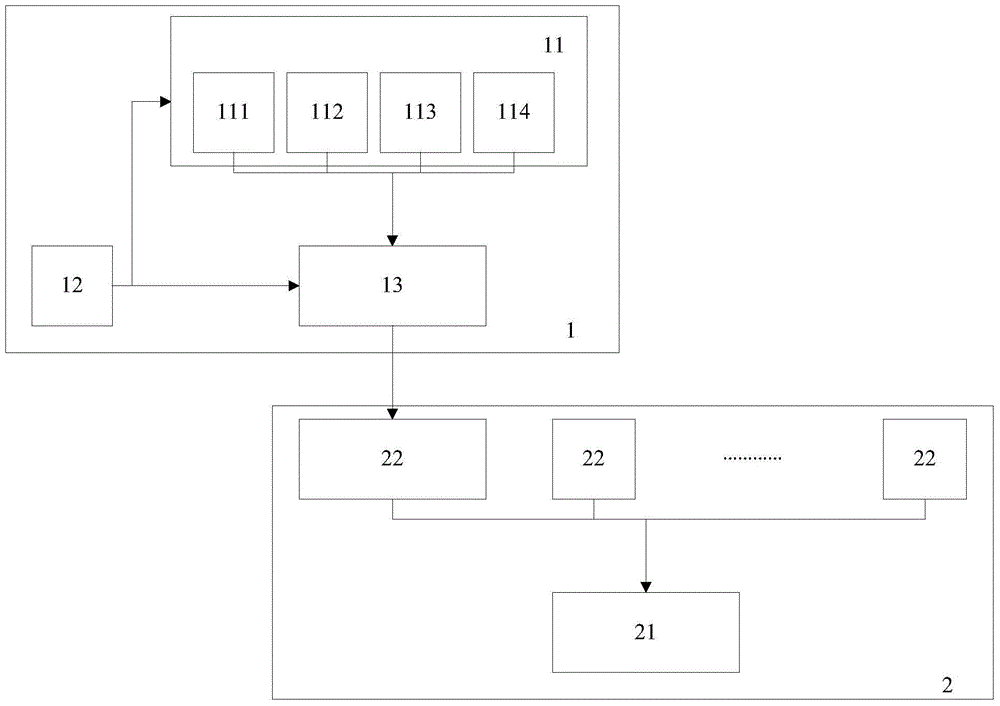

[0023] Such as figure 1 As shown, a monitoring system for an oil-filled cable plugged well, the system includes an interconnected plugged well information collection device 1 and a monitoring platform 2, and the plugged well information collection device 1 is arranged in an oil-filled cable plugged well, including The power supply assembly 12 and the plugging well information collection assembly 11 and the signal converter 13 connected with the power supply assembly 12, the plugging well information collection assembly 11 includes an oil pressure sensor 111 connected with an oil-filled cable, a The water level sensor 112, the Hall current sensor 113 connected with the power supply module and the temperature sensor connected with the oil-filled cable connector and the grounding bar, the oil pressure sensor 111, the water level sensor 112 and the Hall current sensor 113 are respectively connected to the monitor through the signal converter 13. Platform 2 is connected.

[0024] ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap