Gasification combustion system

A technology of combustion system and gasifier, applied in the direction of combustion type, gasification process, combustion method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

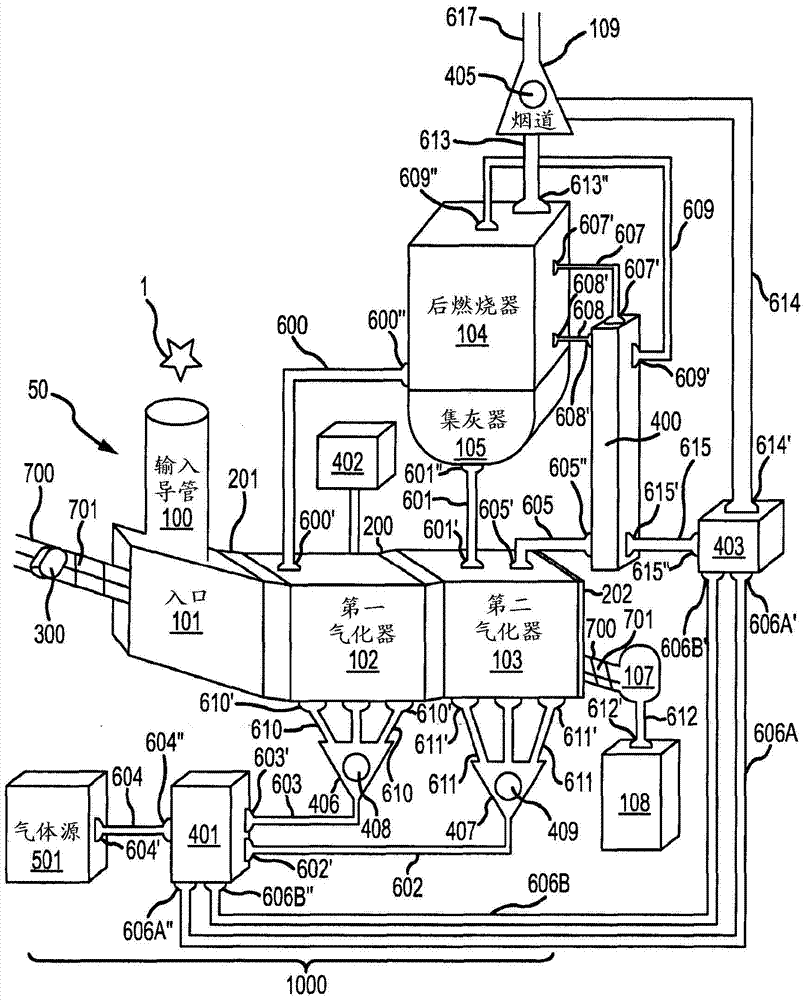

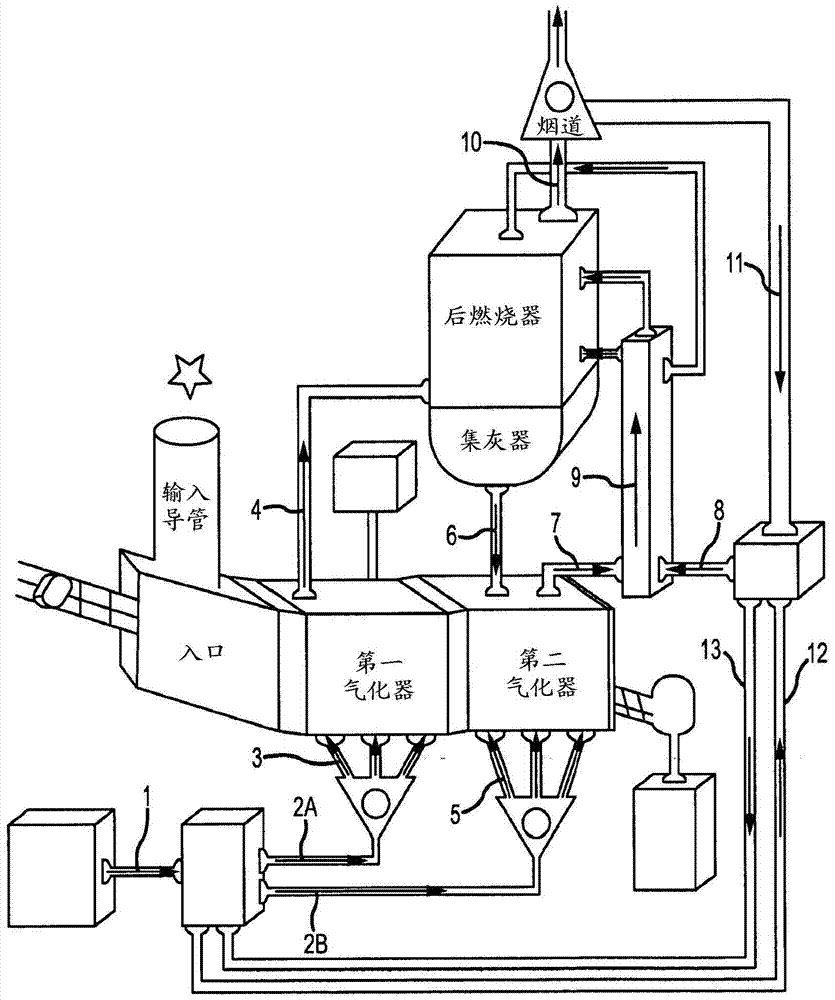

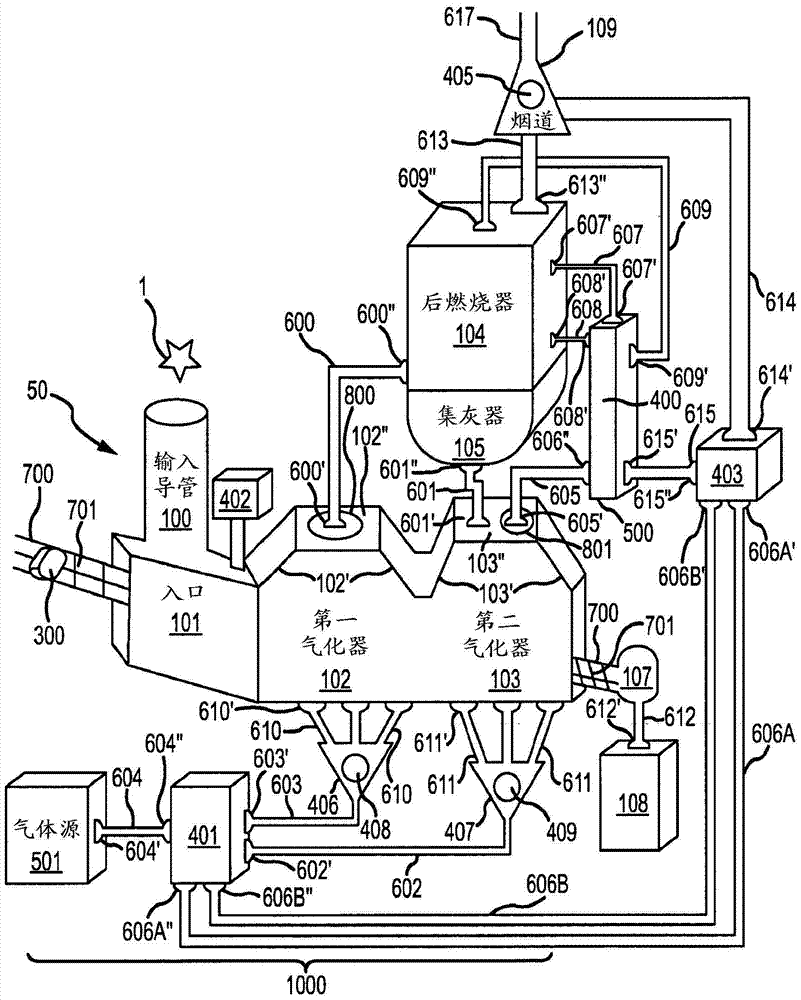

[0033] figure 1 An embodiment of the present invention is shown. The combustion gasification system (referred to as element 50 in a broad sense) includes an inlet 101 for receiving waste 1, a first vaporizer 102, a second vaporizer 103, and a post combustor 104. The waste 1, garbage or waste can be placed in the inlet 101 through the inlet pipe 100 containing the housing. The inlet 101 may include an opening formed by a housing for receiving waste. The processing of waste material 1 usually starts in the first gasifier 102. Processing may include one or more of the following functions: drying, devolatilization, gasification, or combustion. In some embodiments, oil or other combustible materials may be added to waste 1 to promote combustion.

[0034] Once the waste 1 is inside the input 100, it can be pushed through the system 50 by the waste pusher 700. The waste thruster 700 can take the form of a hydraulic cylinder 300 and a grate 701, such as figure 1 As shown, or a self-a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap