Steam dynamic continuous sterilization method and application thereof

A sterilization method and steam technology, applied in application, food preservation, dairy products, etc., can solve the problems of high technical cost and unsuitable for the development of small and medium-sized enterprises, and achieve the effect of reducing waste and improving technical deficiencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

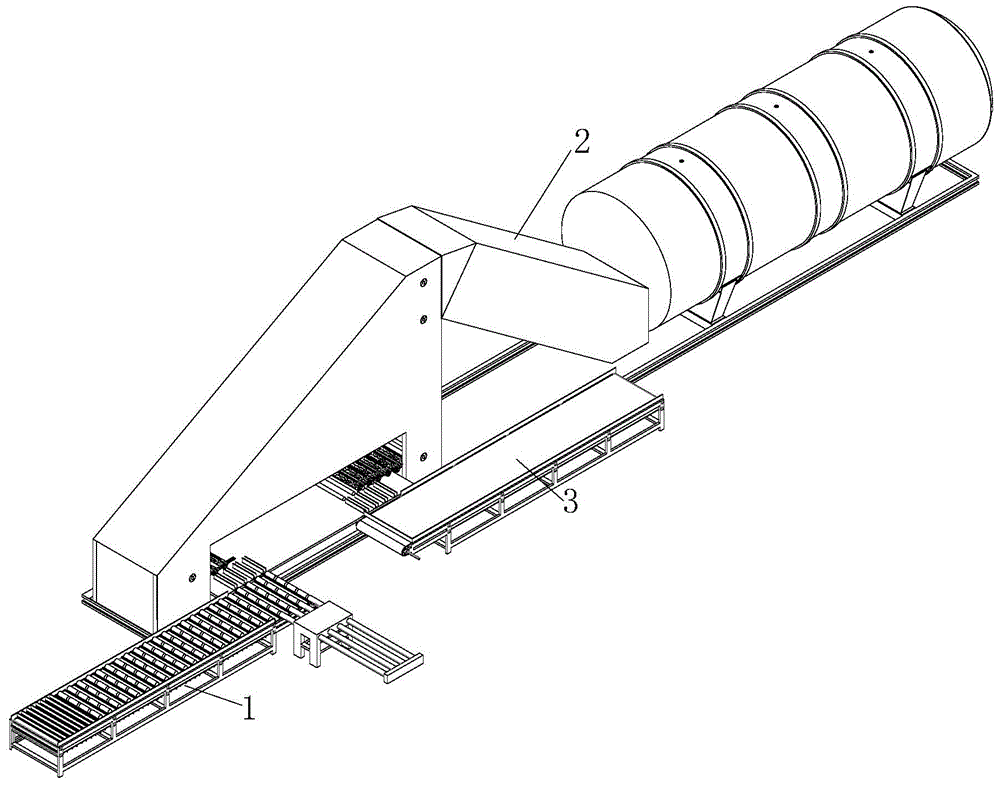

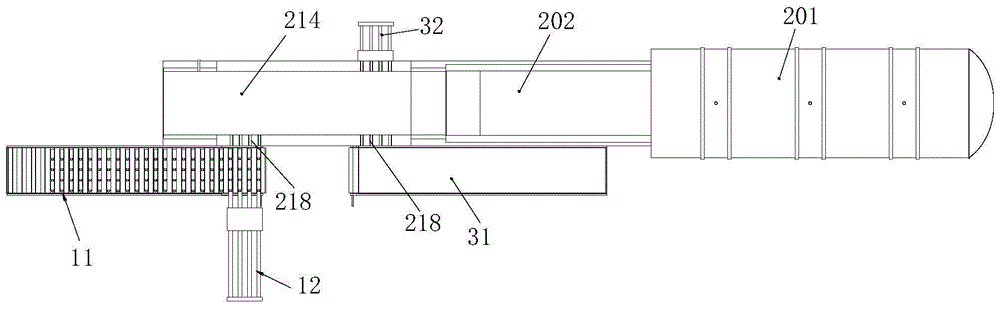

[0023] The automatic sterilization equipment dedicated to the steam dynamic continuous sterilization method includes an automatic feeding mechanism 1, a sterilization mechanism 2, and an automatic unloading mechanism 3.

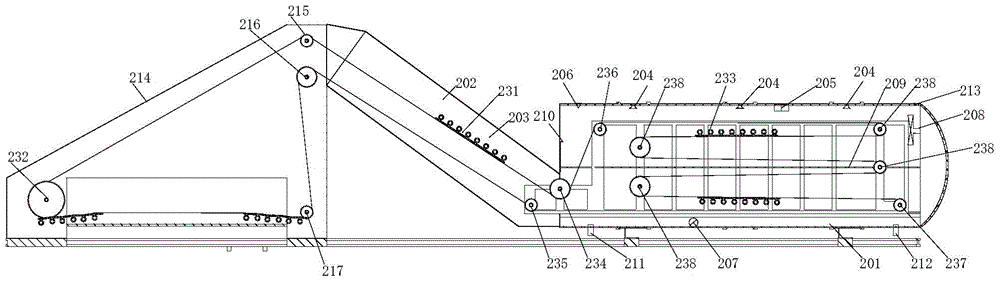

[0024] The sterilization mechanism 2 includes a tank body 201 arranged horizontally, a feeding box body 202 , a feeding rack 214 connected to the feeding box body 202 and a material conveying device 203 .

[0025] The tank body 201 is provided with an insulating layer 213 outside. The lower part of one end of the tank body 201 is provided with an inlet and outlet, and the feeding box 202 is sealed and connected to the inlet and outlet of the tank body 201. The tank body 201 is provided with a horizontal partition 209 higher than the apex of the inlet and outlet, and the partition 209 The inner cavity of the tank body 201 is divided into an upper cavity and a liquid-sealed cooling cavity, and the separator 209 is respectively provided with feeding holes near b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com