Grain Crushing Device for Feed Harvester

A crushing device and harvester technology, which is applied in the field of agricultural machinery, can solve the problems that the grain crushing device cannot be moved out of the working parts, and the power transmission of the grain crushing device cannot be easily disassembled, so as to achieve the effect of convenient maintenance and high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

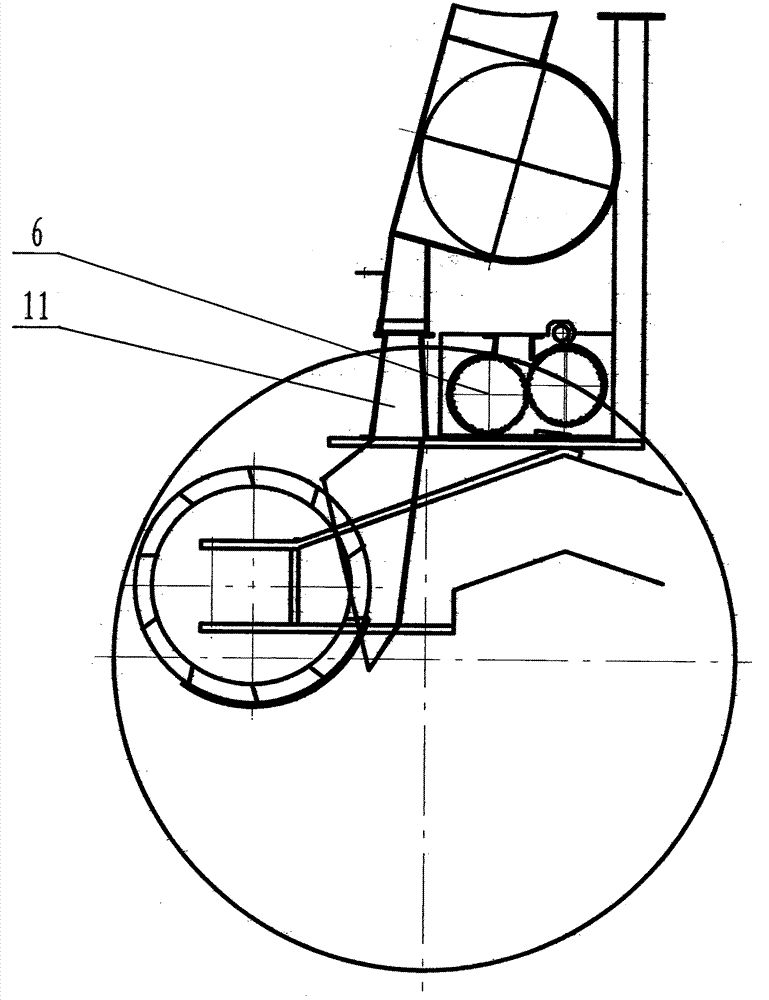

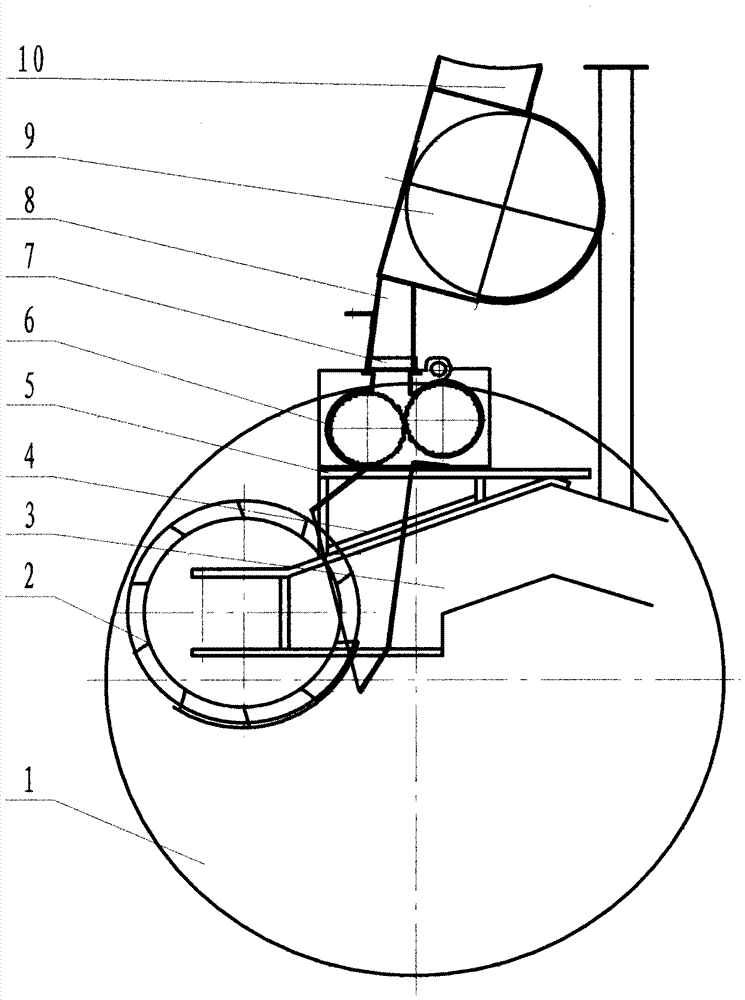

[0021] like Figure 1 to Figure 4 As shown, a grain crushing device for a feed harvester according to the present invention comprises a lower guide barrel (4), a grain crushing component (6), a sealing strip (7), an upper guide barrel (8), a transmission mechanism and a backup guide A barrel (11); the grain crushing part (6) is connected to the grain crushing fixing frame (5), and can move and fix along the grain crushing fixing frame (5); the grain crushing part (6) is fixedly connected At the front end of the grain crushing fixing frame (5), the lower feeding cylinder (4) is connected to the discharge port of the chopper drum (2) on the feed harvester and the feed inlet (22) below the grain crushing part (6). (8) Connect the feed outlet (15) above the grain crushing component (6) and the feed inlet of the throwing fan (9) on the feed harvester.

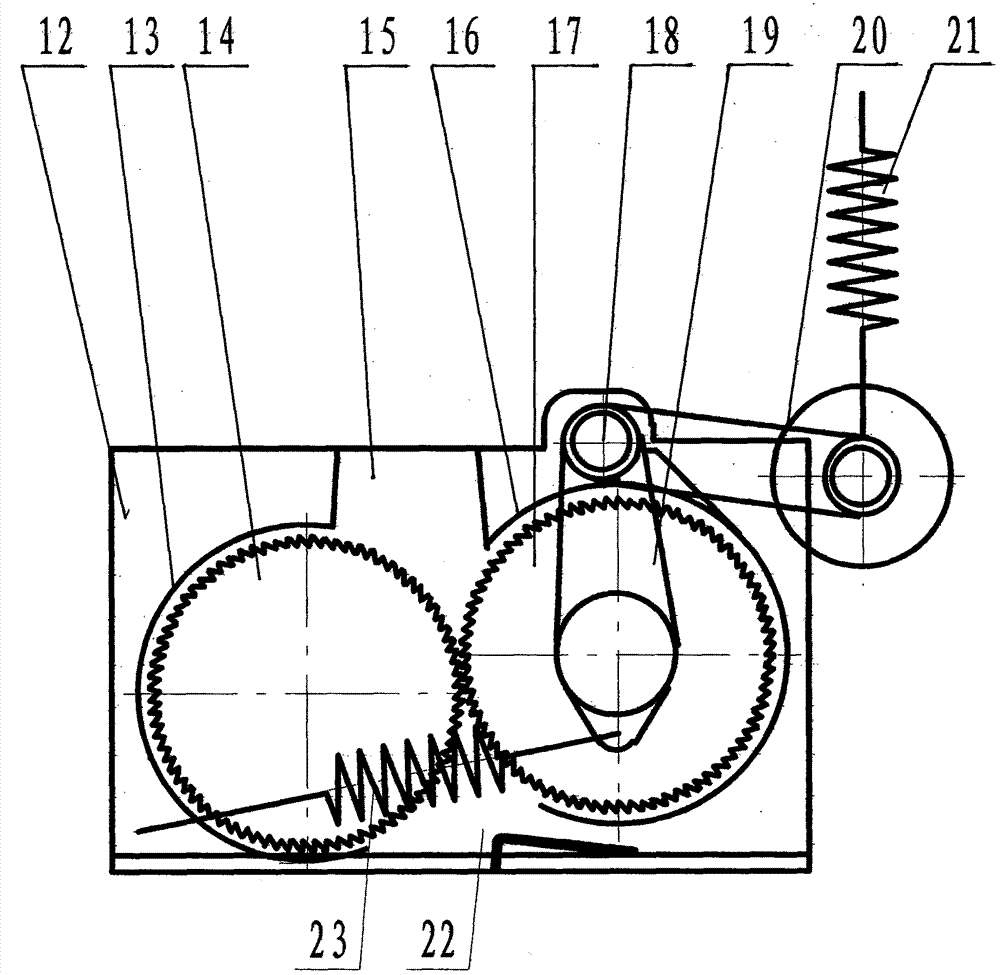

[0022] like image 3 As shown, the grain crushing part (6) comprises a fixed round roller (14), a front cover (13), a floating r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com