Plastic-removing and rubbing machine for preparation of protected vegetable straw fertilizer

A vegetable and straw technology, which is applied in the field of facility vegetable straw fertilizer cleaning plastic kneading machine and kneading machine, can solve the problems of increasing the production cost of organic fertilizer, affecting the fermentation cycle of organic fertilizer, and being unable to knead vegetable straw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

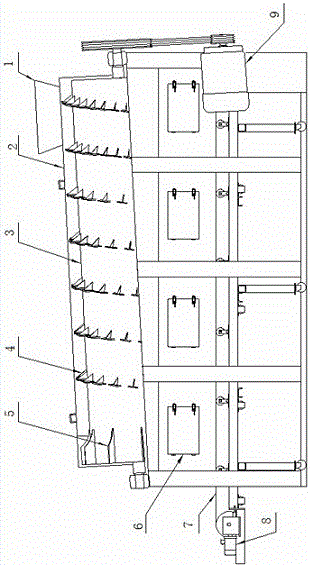

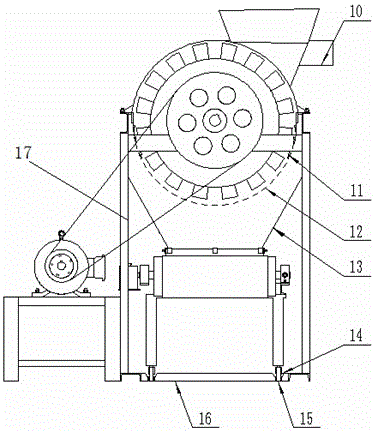

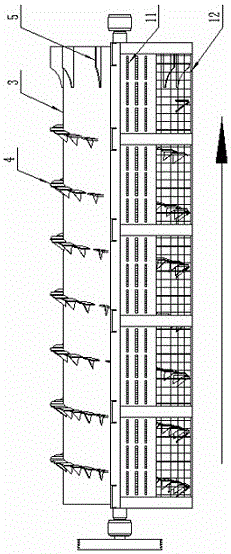

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

[0023] A clear plastic kneading machine for making fertilizer from vegetable stalks, including a support frame 17, a cover body 2, a roller 3, a screen 12 and a motor 9; and the coarse material port 10; the motor 9 is placed on one side of the drum 3, and the motor 9 is linked with the drum 3 through a belt pulley transmission mechanism; A large dial 5, the lower part of the drum 3 is provided with a screen 12, the lower part of the drum 3 is provided with a lower hopper 13, there is a screening rubbing chamber between the drum 3 and the screen 12, and a plurality of rubbing plates 11 are fixed on the drum 3 It is parallel to the axis of the drum 3 and located at the screening and kneading chamber.

[0024] In this embodiment, the drum 3 is located in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com