Micro sprinkler with sprinkling modes variable

A micro-spray head, variable technology, applied in the direction of spraying device, spraying device, etc., can solve problems such as single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

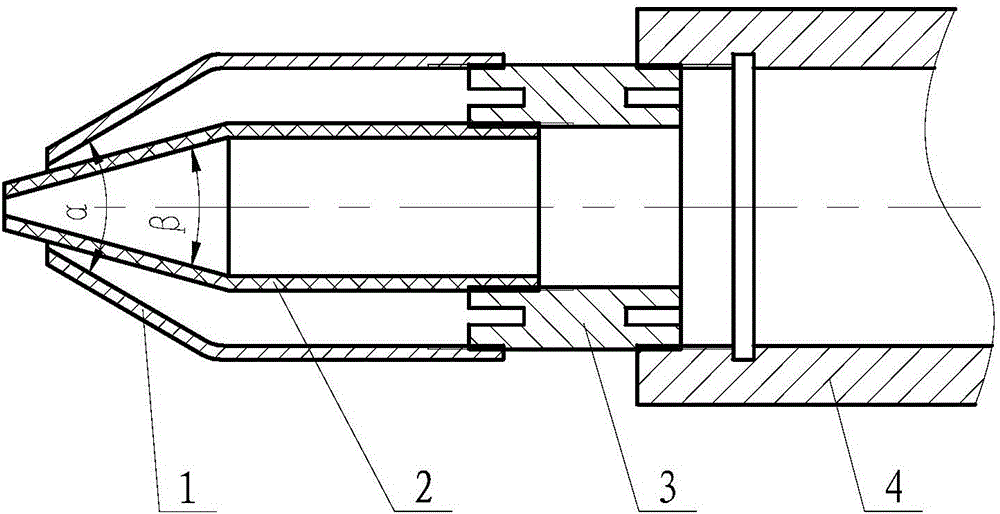

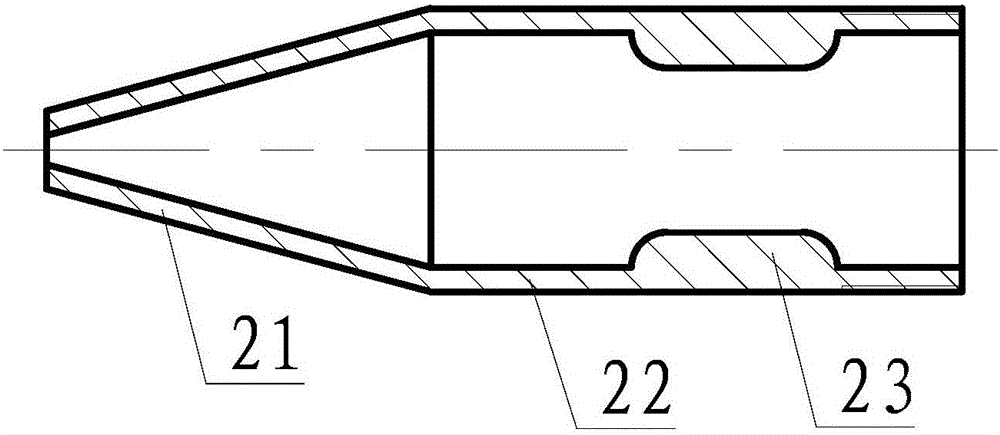

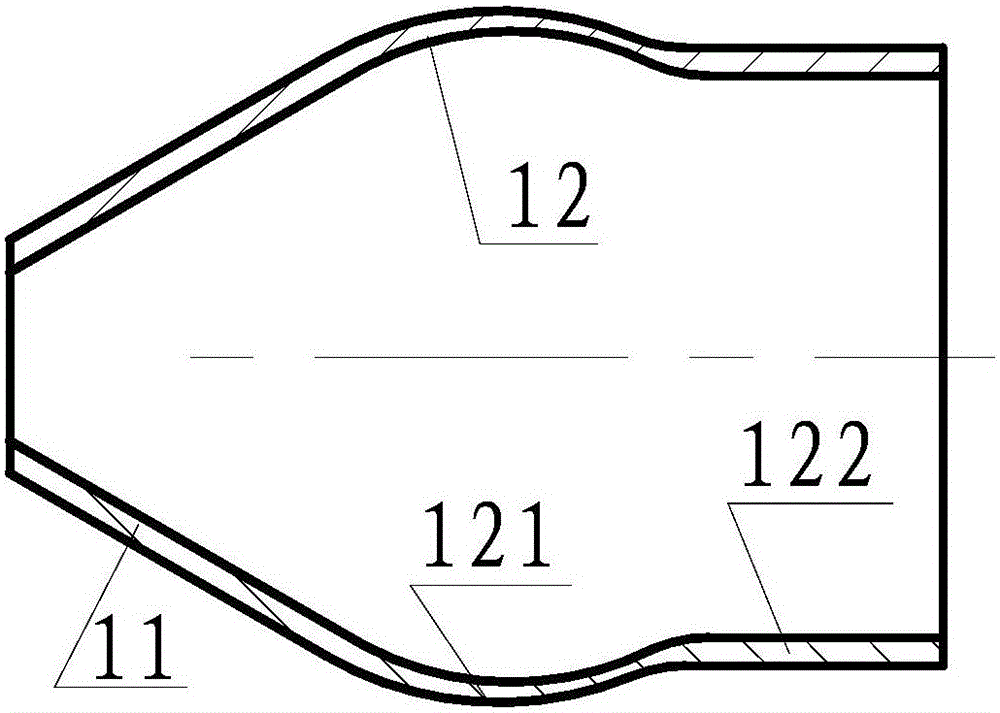

[0020] Refer to the attached figure 1 , the micro-spray head with variable atomization form of the present invention includes atomizing nozzle 1, rectifying nozzle 2, connecting sleeve 3 and main pipeline 4, characterized in that the connecting sleeve 3 is connected with the main pipeline 4 through threads, and the rectifying nozzle is 2 is assembled on the inner side of the connecting sleeve 3 through a threaded connection, and the atomizing nozzle 1 is assembled on the outside of the connecting sleeve 3 through a threaded connection; the rectifying nozzle 2 includes an expansion section 21 and a rectifying section 22; The atomizing nozzle 1 includes a shrinkage Atomization section 11 and arc-shaped atomization section 12.

[0021] The rectifying nozzle 2 is installed concentrically with the atomizing nozzle 1, the rectifying nozzle 2 is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com