Programmable intelligent electric spindle

An electric spindle and intelligent technology, applied in the direction of large fixed members, maintenance and safety accessories, driving devices, etc., can solve the problems of single performance control, high real-time requirements, and unreported problems, so as to achieve simple structure and meet processing quality Requirements, effect of suppressing spindle vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

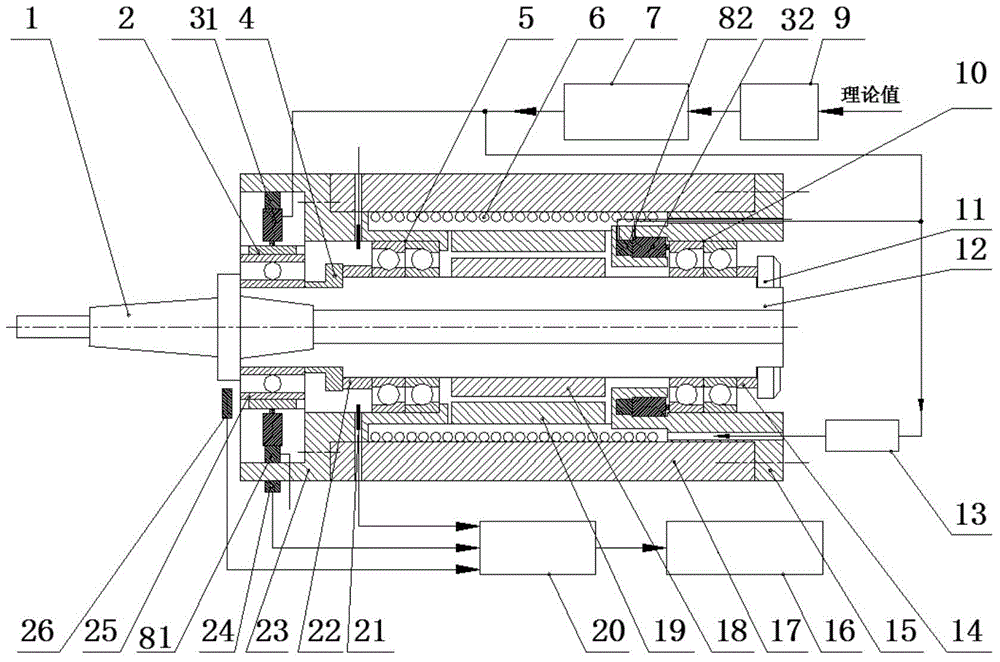

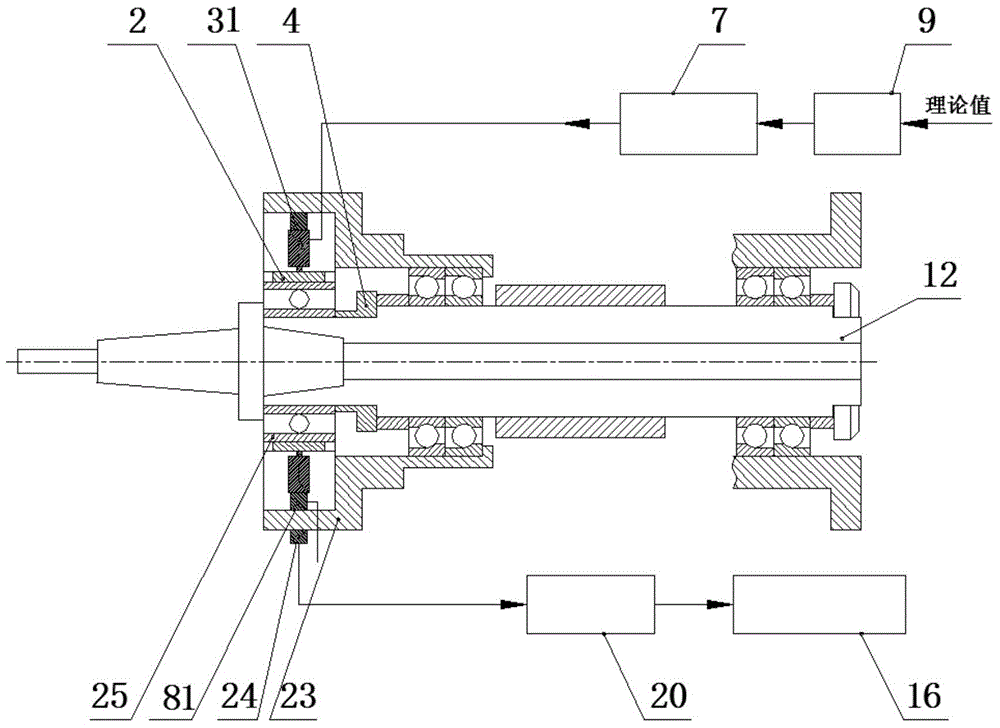

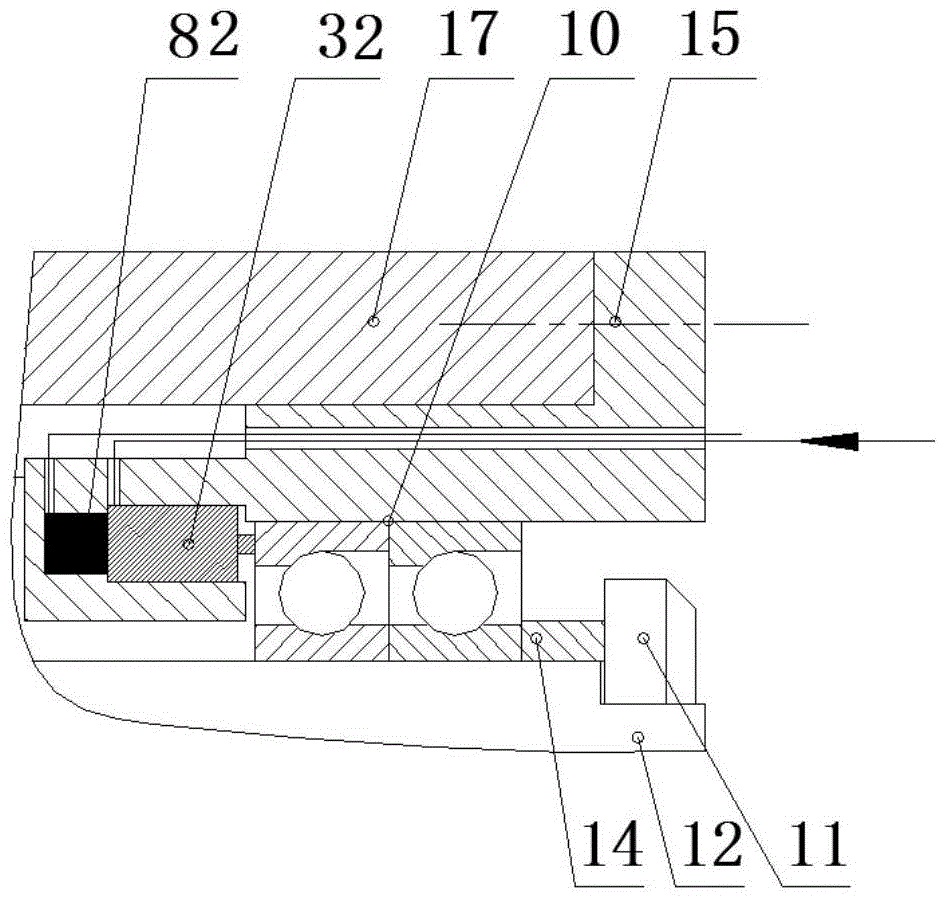

[0030] The present invention is described in further detail below in conjunction with accompanying drawing:

[0031] refer to figure 1 , figure 2 , image 3 and Figure 4 , the programmable intelligent electric spindle of the present invention includes a front bearing seat 23, a rear bearing seat 15, a main shaft 12, a motor rotor 18, a motor stator 19, a cooling water jacket 6, an actuating bearing 25, an annular pressure block 2, a knife Handle 1, controller 9, coolant input pipe, coolant output pipe, and housing 17 of hollow structure; front bearing group 5 and rear bearing group 10 are installed on the front end and rear end of main shaft 12 respectively, and front bearing seat 23 and The rear bearing seat 15 is respectively socketed in the front and rear ends of the housing 17, the motor rotor 18 is socketed in the middle section of the main shaft 12, and the motor rotor 18 is located between the front bearing group 5 and the rear bearing group 10, and the motor stato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com