Pull-type full-automatic sun protection device for solar vehicle

A solar car, fully automatic technology, applied in vehicle components, transportation and packaging, removable outer sheaths, etc., can solve the lack of feasibility, not considering the deployment mechanism, unable to close the sunshade to the window and windshield, etc. problems, to achieve the effect of improving adaptability and reliability, good heat dissipation, and good sun protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

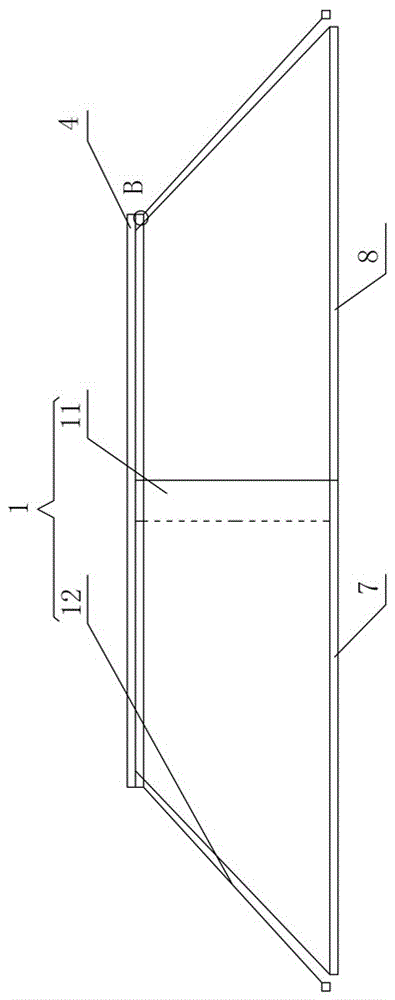

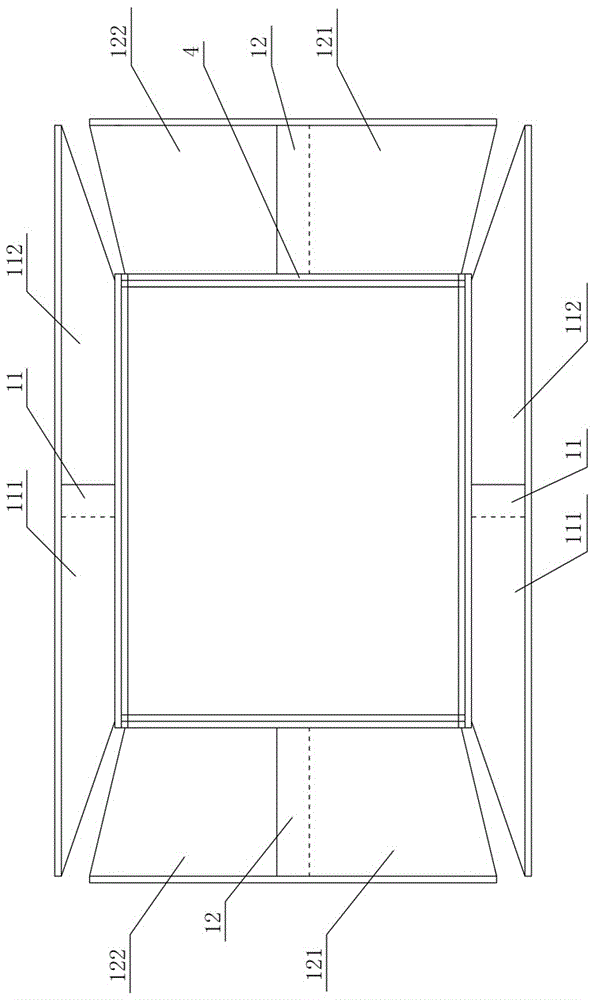

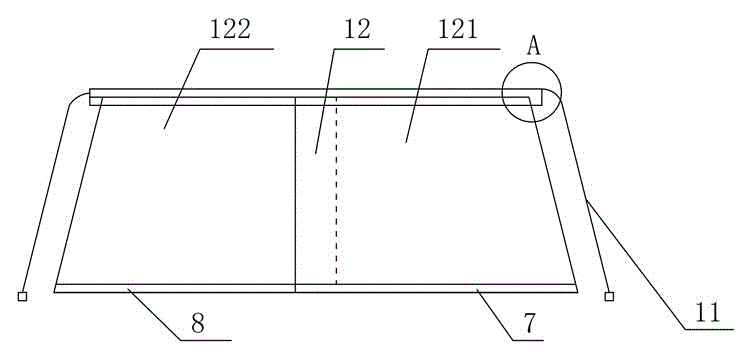

[0037] Figure 1 to Figure 17 It shows an embodiment of the pull-type automatic sun protection equipment for solar vehicles of the present invention, the sun protection equipment includes a sun protection clothing 1, a solar photovoltaic panel 2, a storage battery 3 and a heat-insulating retractable shelf 4, and the sun protection clothing 1 includes and The sun-proof side clothing 11 and the sun-proof top clothing 12 fitted with the car windshield, the sun-proof side clothing 11 and the sun-proof top clothing 12 are all movably connected with the heat insulation retractable layer frame 4, and the sun-proof side clothing 11 includes Two trapezoidal front side garments 111 and rear side garments 112, sun protection top garment 12 comprise two trapezoidal left top garments 121 and right top garment 122, heat insulation retractable shelf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com