Magnetic separator

A magnetic separator and magnetic separation device technology, which is applied in the direction of pile separation, object separation, and thin material processing, can solve the problems of high labor cost, easy to stick together, and low efficiency of manual separation, so as to reduce labor cost and cost Low cost and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

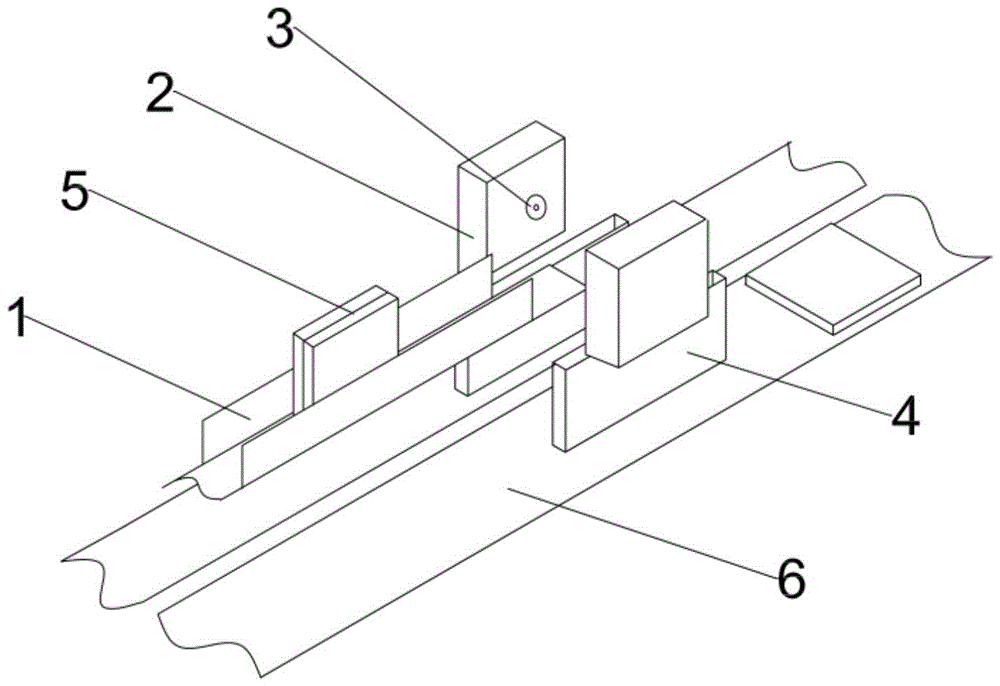

[0014] The reference signs in the description of the drawings are: conveying trough 1, electromagnet 2, photoelectric sensor 3, channel 4, valve plate 5, and conveyor belt 6.

[0015] like figure 1 As shown, this technical solution provides a magnetic separator, including a transmission part and a separation part. The transmission part includes a conveying trough 1 for the vertical transmission of the valve plate 5, so that the two plates of the valve plate 5 correspond to the direction of the electromagnet 2 to facilitate separation. Electromagnet 2 to its separation.

[0016] The separation part includes two electromagnets 2, and the two electromagnets 2 are respectively fixedly installed on both sides of the conveying tank 1, and the two side walls of the conveying tank 1 corresponding to the electromagnets 2 are provided with notches, and the width of the notches is at least larger than that of the valve. The length of the plate 5, so that the electromagnet 2 will not be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com