A kind of ozone-resistant stabilizer bar bushing and preparation method thereof

A stabilizer bar bushing and ozone-resistant technology, applied in the field of automobile suspension lateral stabilizer bars, can solve the problems of no ozone resistance, short service life, easy failure, etc., and achieve increased cross-linking density, improved durability, and increased tensile strength. Effects of strength and tensile stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

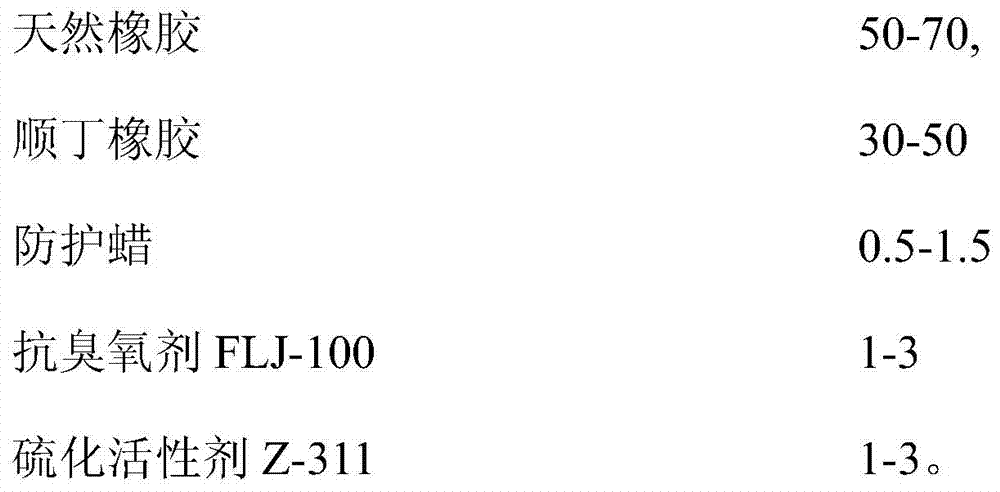

[0054] A stabilizer bushing is prepared from the following raw materials in parts by weight:

[0055]

[0056] The preparation method of the above-mentioned stabilizer bushing comprises the following steps:

[0057] (1) Use the above formula to prepare materials, and send the raw materials into the internal mixer, mix for 5-7 minutes, and deglue at 110°C to obtain the mixed rubber;

[0058] (2) Carrying out kneading and molding the mixed rubber obtained in step (1) in an open mill at a temperature of 70-80° C. to obtain a strip shaped part;

[0059] (3) Put the strip-shaped molding into the barrel of the injection vulcanizer, under the pressure of 170-190kgf / cm 2 1. Carry out vulcanization treatment at a temperature of 160-170°C, the vulcanization time is 240-360 seconds, and the stabilizer bar bushing is obtained after cooling and trimming.

Embodiment 2

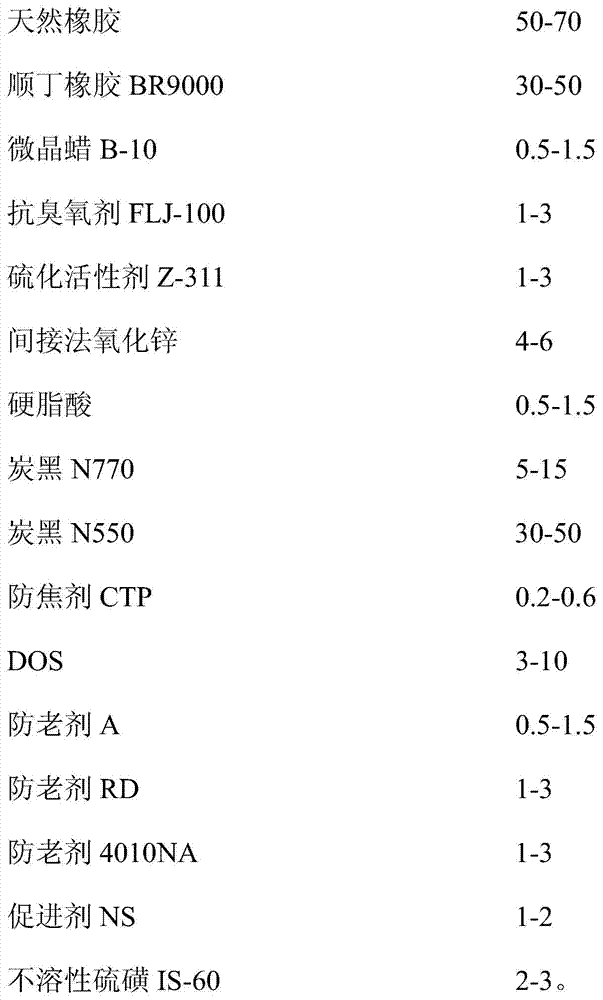

[0061] A stabilizer bushing is prepared from the following raw materials in parts by weight:

[0062]

[0063] Its preparation method is with embodiment 1.

Embodiment 3

[0065] A stabilizer bushing is prepared from the following raw materials in parts by weight:

[0066]

[0067] Its preparation method is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com