Luoyang shovel

A Luoyang shovel and shovel blade technology, applied in the field of Luoyang shovel, can solve the problems of increased difficulty, increased labor intensity of operators, disturbance of soil samples, etc., and achieve the effects of high soil sample collection rate, improved exploration efficiency, and avoiding stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

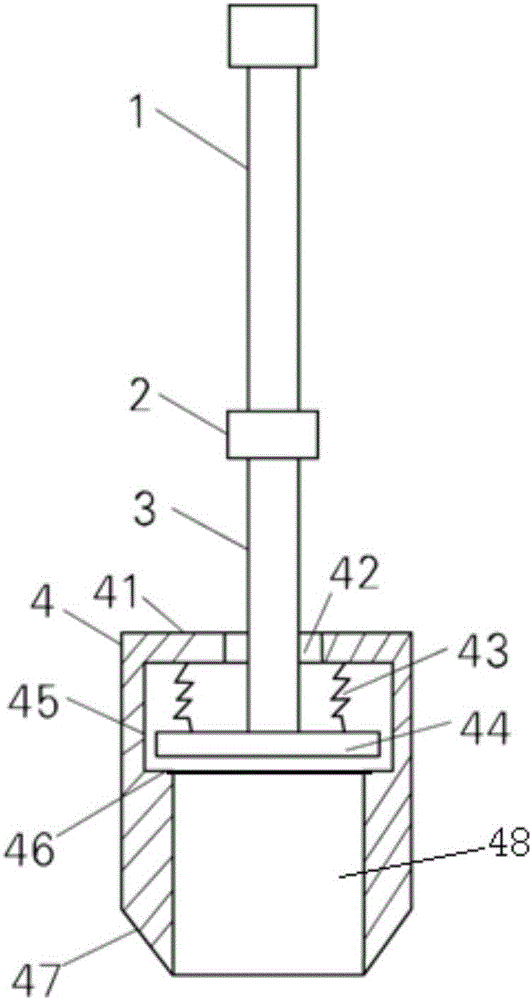

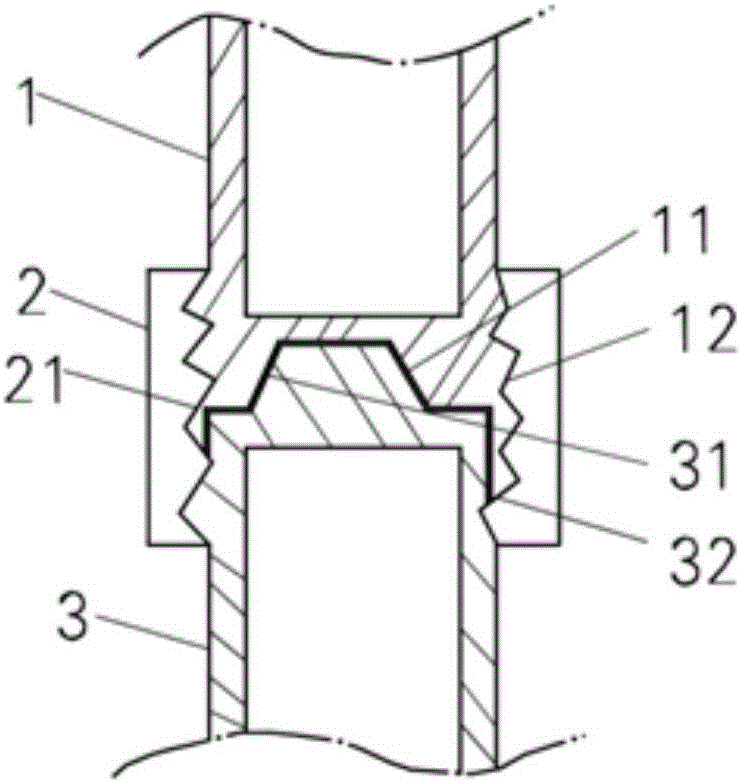

[0016] As shown in the figure, the present invention includes an extension rod 1, a hollow round table 11 recessed in the lower end of the extension rod, an outer screw thread 12 at the lower end of the extension rod, a joint sleeve 2, an inner thread buckle 21 of the joint sleeve, a weighting rod 3, and a weighting rod Protruding solid round table 31, outer screw thread at the upper end of the weighting rod 32, blade 4, blade top cover 41, center hole of blade top cover 42, spring 43, impact plate 44, impact cylinder 45, impact cylinder step 46, blade Bottom edge 47, earth taking cylinder 48. The extension rod 1 and the weighting rod 3 are connected by the thread of the joint sleeve 2, the weighting rod 3 passes through the central hole 42 of the top cover of the blade and is connected with the impact plate 44, and the spring 43 is connected between the impa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com