A test device for ultra-high pressure extrusion servo system

A squeeze-type servo and test device technology, which is applied in the test field of rocket servo system, can solve the problems of incomplete ground test test coverage, failure to test the pressure bearing and air sealing performance of electric explosion valve, and achieve test coverage Complete and achieve the effect of positioning assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

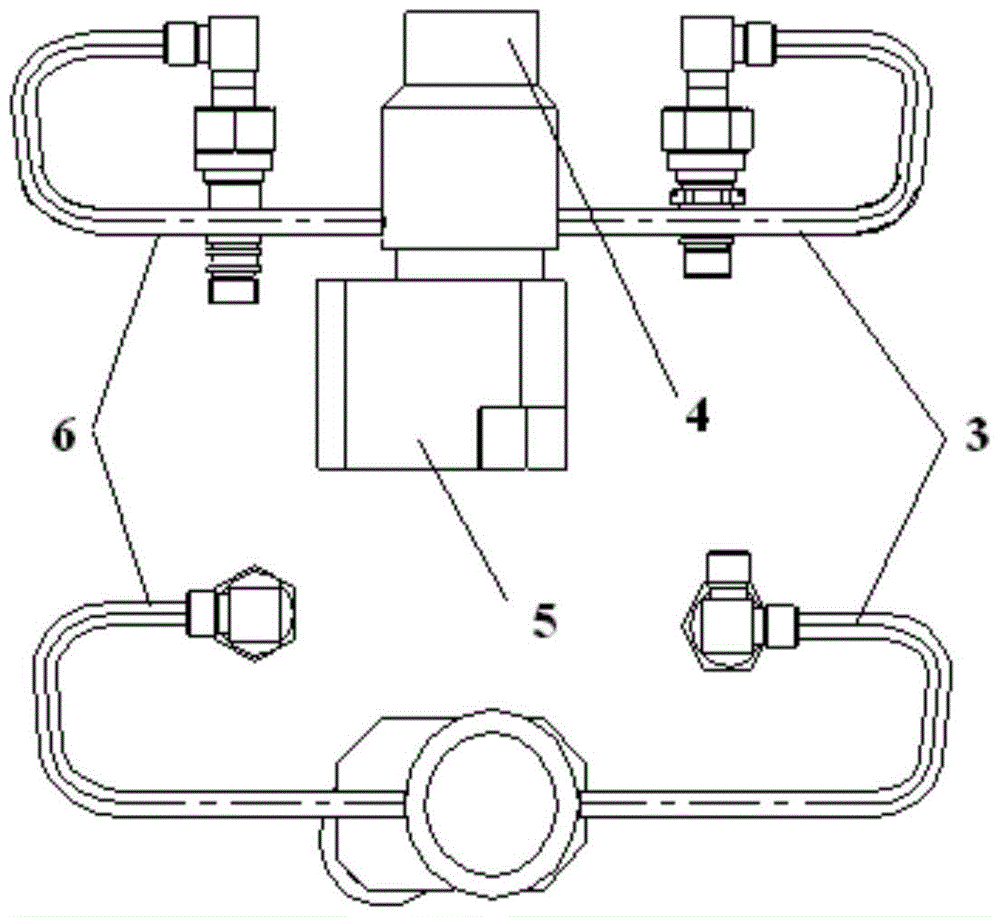

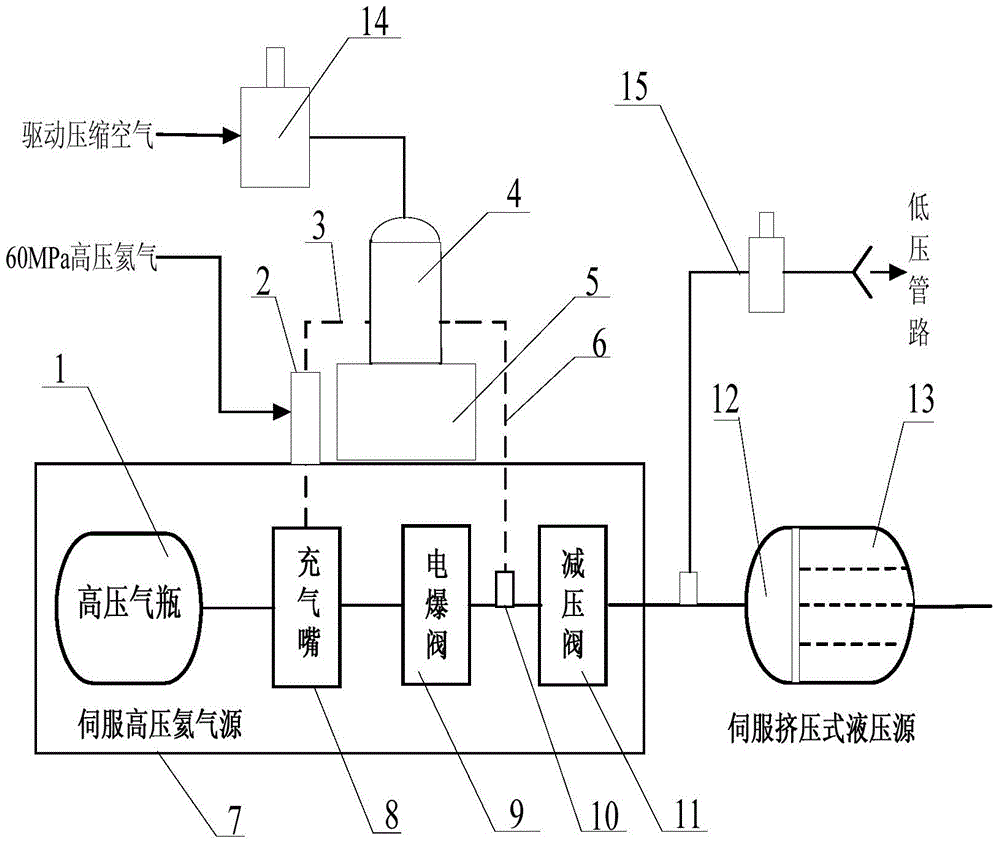

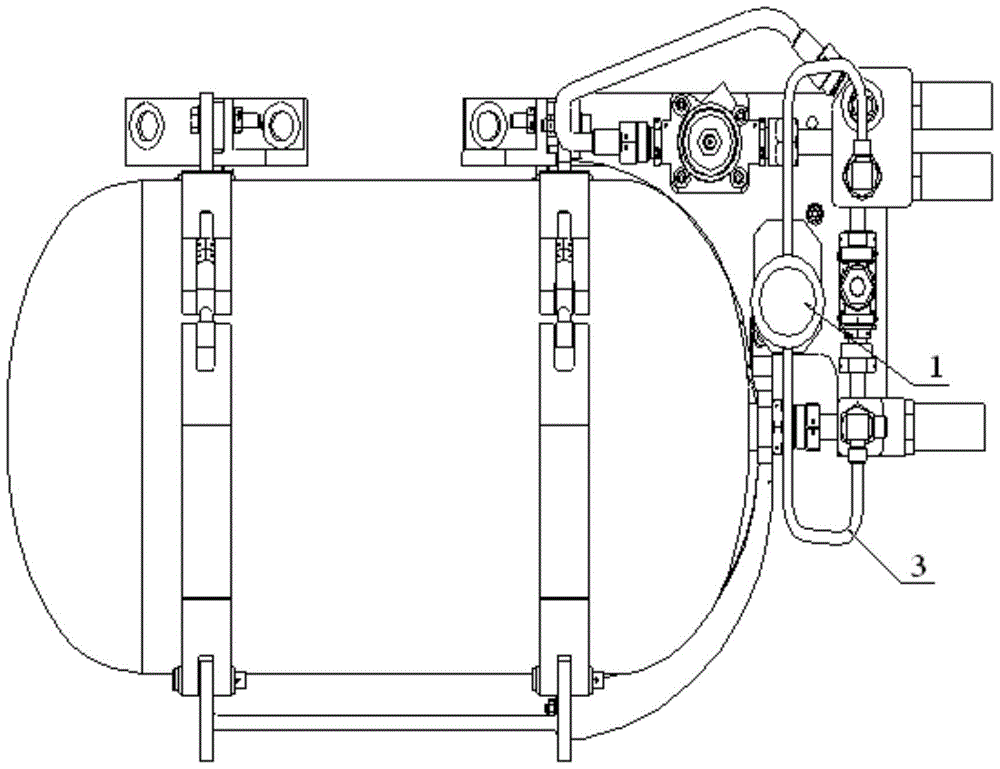

[0025] The technical solution of the present invention is: a test device for an ultra-high pressure extrusion servo system, which simulates the working state of the electric explosion valve in the state of the working gas source of the extrusion servo system on the arrow. In the state where the high-pressure helium source has been equipped with an electric explosion valve, use the interface of the gas filling nozzle on the high-pressure helium source and the online test port of the pressure reducing valve as the interfaces at both ends of the equivalent simulation device, so that the equivalent simulation device is installed in parallel on the electric explosion valve. On the high-pressure air circuit of the explosion valve; the high-pressure hose is replaced by a stainless steel hard pipe assembly, and at the same time, one end of the stainless steel hard pipe is processed with a tapered thread, which is directly connected to the high-pressure air control switch valve body, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com