Butterfly valve with both-way sealing function

A two-way sealing and functional technology, applied in the direction of lift valves, valve devices, engine components, etc., can solve the problems of affecting the sealing performance of the sealing ring, position deviation, medium backflow, etc., achieve reliable two-way sealing, and overcome the effect of insufficient sealing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

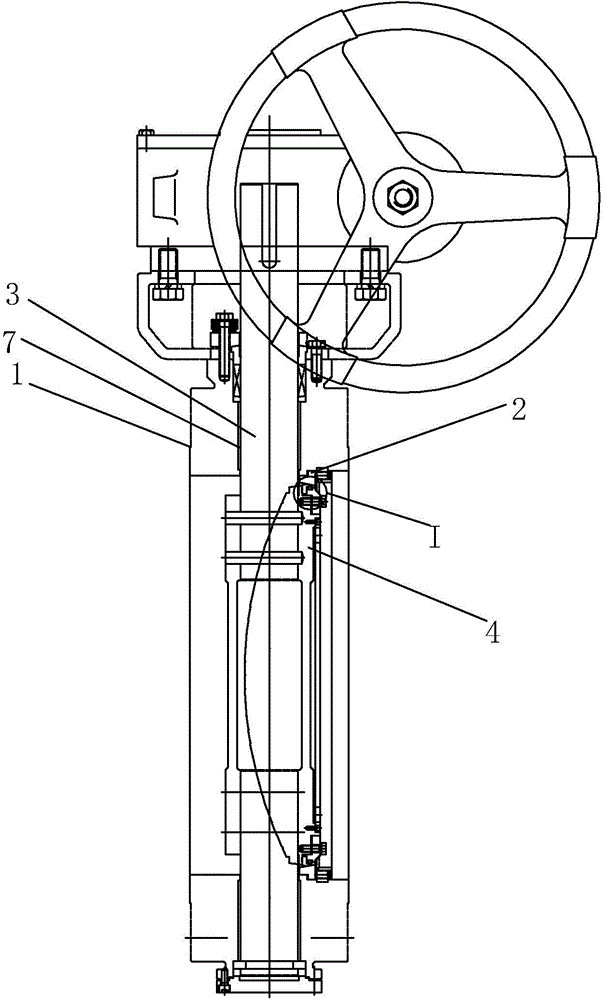

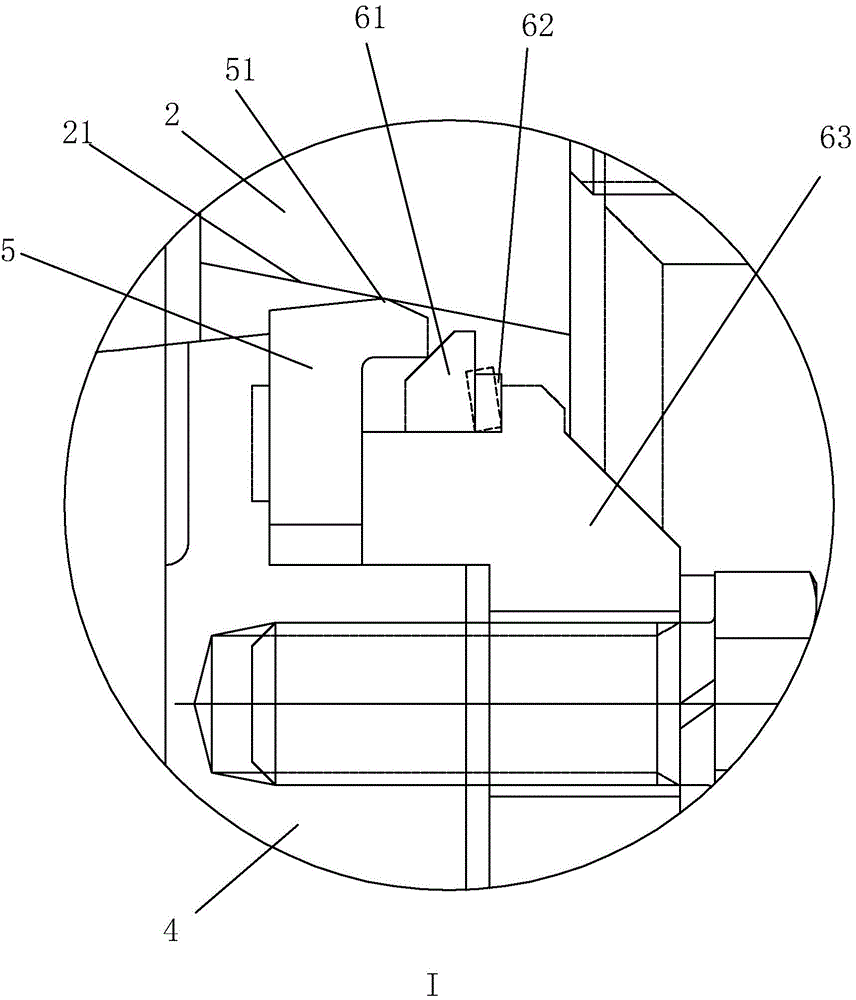

[0016] refer to Figure 1 to Figure 2 The embodiment of the butterfly valve with bidirectional sealing function of the present invention will be further described.

[0017] A butterfly valve with two-way sealing function, comprising a valve body 1, a valve seat 2 and a valve stem 3, the valve seat 2 is set in the valve body 1, the valve stem 3 is provided with a butterfly plate 4, and the butterfly plate 4 is provided with a sealing ring 5, and the sealing ring 5 is in conflict with the inner wall of the valve seat 2, the inner wall of the valve seat 2 is provided with an inclined part 21, and the inclined part 21 is arranged around the inner wall of the valve seat 2, and the opening of the side of the valve seat 2 opposite to the liquid inlet is larger than that of the other side, wherein the sealing The cross section of the ring 5 is in the shape of a "7", and the top of the sealing ring 5 is provided with a top portion 51, and the top portion 51 conflicts with the inner wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com