A Multilayer Vibration Isolation and Shock Resistant Pipeline Support

A pipeline support and vibration isolation technology, which is applied in the direction of pipeline supports, pipes/pipe joints/pipe fittings, mechanical equipment, etc., to achieve the effects of improving vibration isolation, compact structure, and enhancing impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

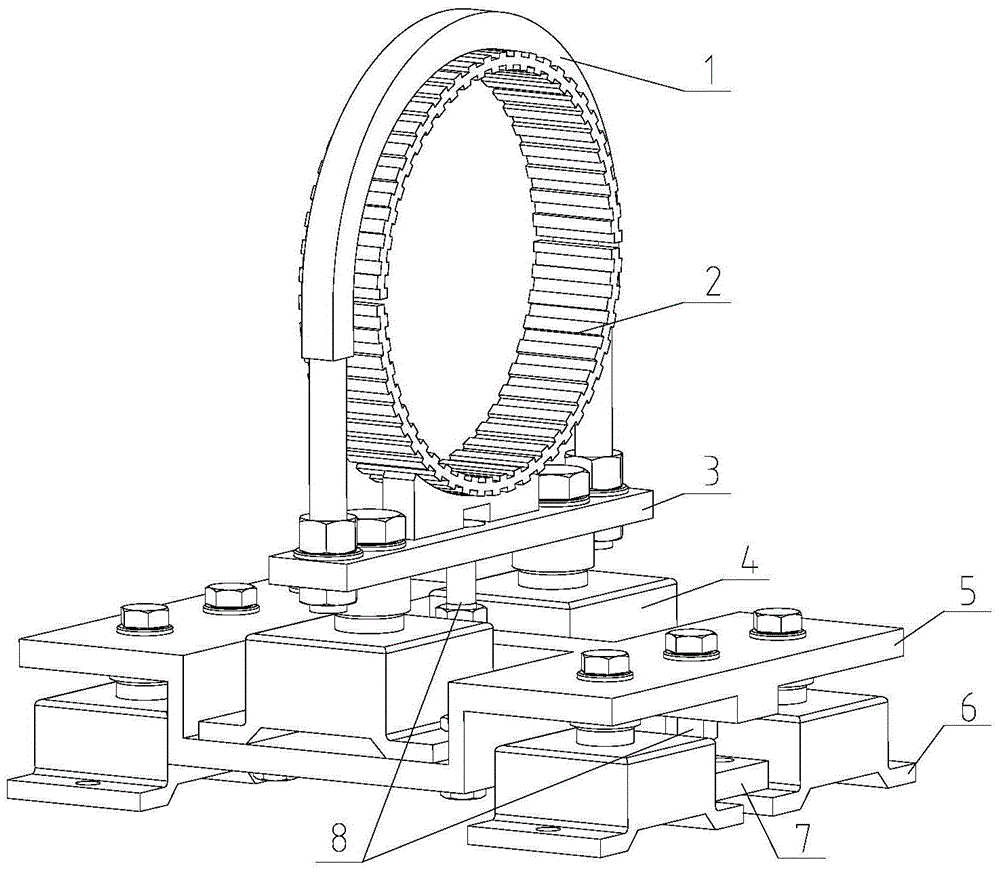

[0038] The invention provides a multi-layer vibration isolation and anti-shock pipeline support, see the attached figure 1 , including: upper clamp 1, damping ring 2, lower clamp 3, upper vibration isolator 4, intermediate mass 5, lower vibration isolator 6, limit block 7 and limit pin 8;

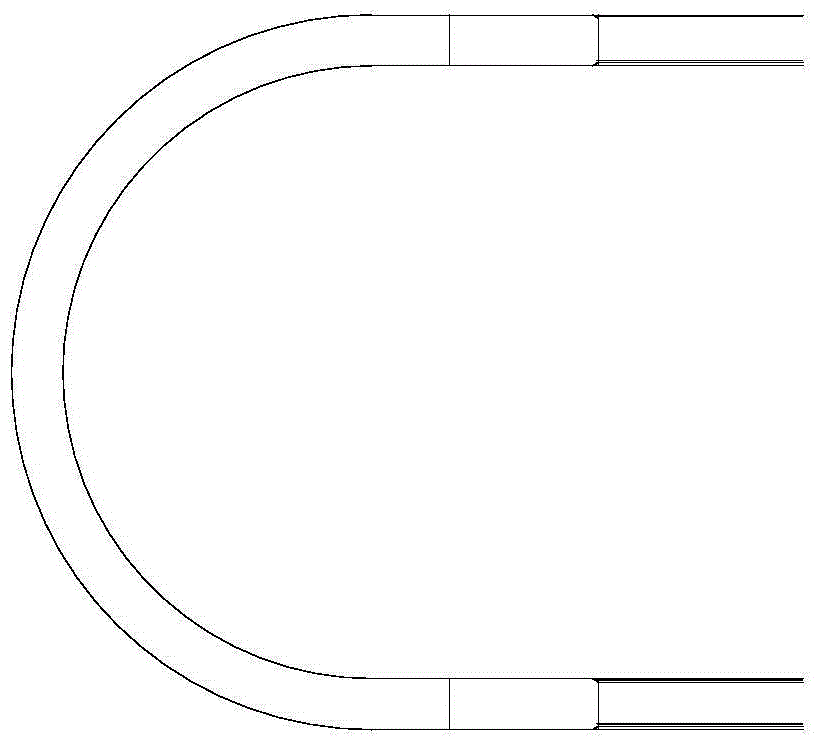

[0039] See attached figure 2 , the upper clamp 1 is a U-shaped structure with a square cross section, and the two ends of the U-shaped structure are provided with external threads;

[0040] The damping ring 2 is a split structure;

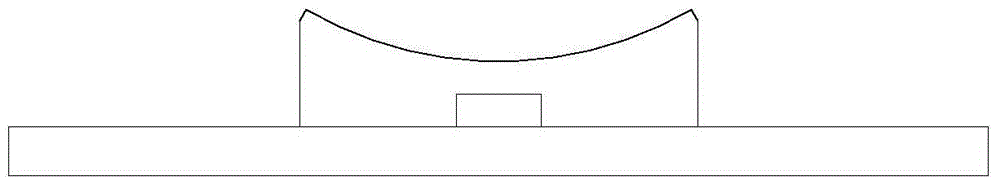

[0041] See attached image 3 , 4 , the lower clamp 3 is composed of a strip plate and a boss, and the strip plate has a plurality of through holes, wherein the through hole located in the middle of the strip plate is a limiting hole, and the through holes at both ends are installation holes ; The upper surface of the boss is an arc surface, and the lower surface has a groove; the boss is fixed on the strip plate, and the groove on the lower surface of the b...

Embodiment 2

[0055] On the basis of Embodiment 1, the vibration-damping ring 2 is made of a rubber pad or a vibration-isolation belt. The vibration-isolation belt has excellent vibration-isolation performance and improves environmental adaptability.

Embodiment 3

[0057] On the basis of Embodiment 1 or 2, the clamp on the square section can be changed to the clamp on the cylindrical section, which is easier to process for the U-shaped structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com