Full-automatic control hydraulic multifunctional trolley

An automatic control valve, fully automatic technology, applied in the direction of engine lubrication, lubricating oil control valve, engine components, etc., can solve problems such as single function, difficulty in meeting various functional requirements of different hydraulic lubrication systems, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing:

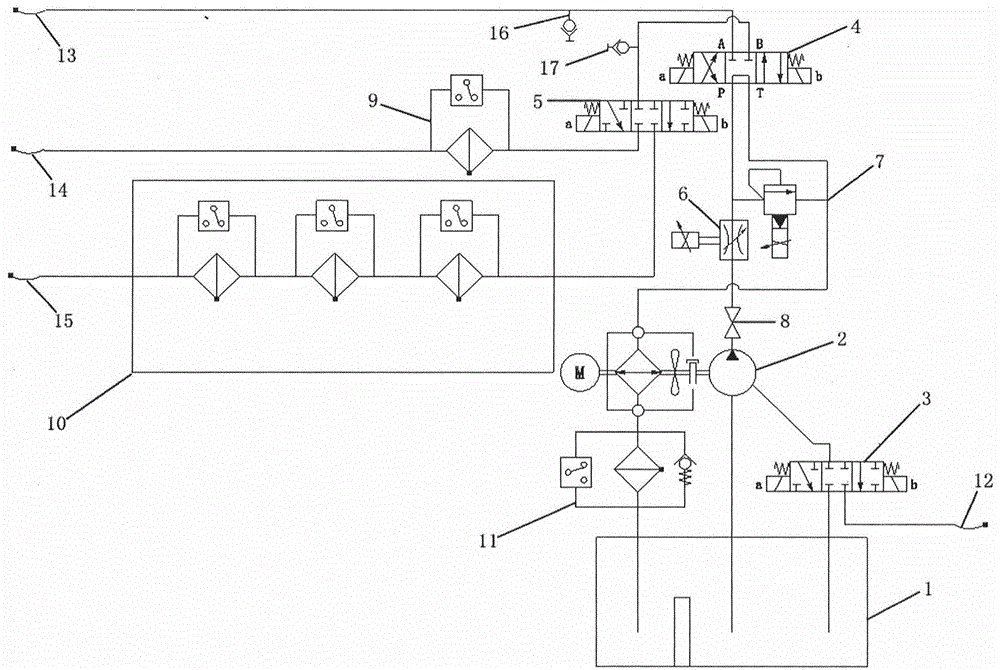

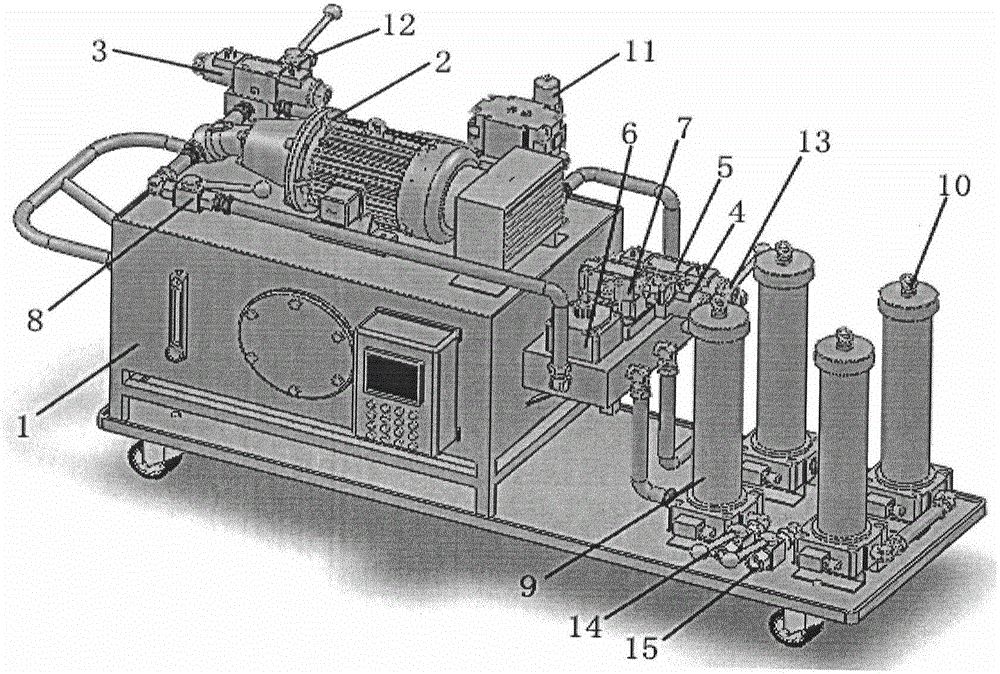

[0010] The hydraulic system schematic diagram of a fully automatic control hydraulic multifunctional trolley is as follows: figure 1 As shown, oil tank (1), system pump group (2), oil suction switching valve (3), function switching valve 1 (4), function switching valve 2 (5), system flow automatic control valve (6), system pressure automatic Control valve (7), main oil circuit control valve (8), system refueling filter (5u) (9), system circulation filter group (25u, 10u, 5u) (10), trolley self-circulation filter (5u) (11), car oil suction interface (12), system pressure interface (13), system refueling interface (14), system circulation filter interface (15), system pressure measurement point (16), system refueling pressure measurement point (17) ;

[0011] Its specific operation process is as follows:

[0012] a. Realization of system online circulation filter function ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com