Calibration method for textile spinning machine roller entry and exit fixing gauge

A technology of textile spinning frame and calibration method, which is applied in the direction of mechanical roughness/irregularity measurement, mechanical device, mechanical measuring device, etc., which can solve the impact of flat car quality, technical requirements drop, standard bar cylindrical surface and base Problems such as plane verticality deviation, to achieve the effect of promoting product quality, improving flat car quality, and accurate calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

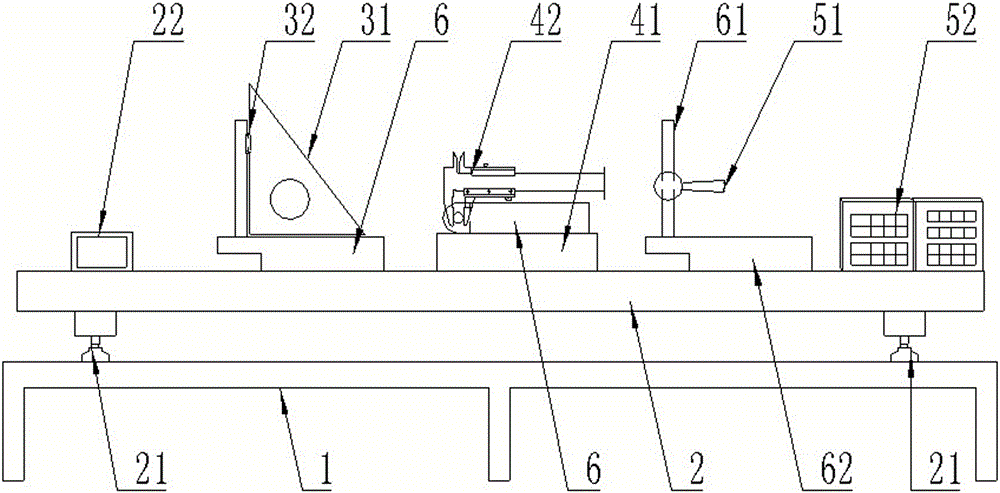

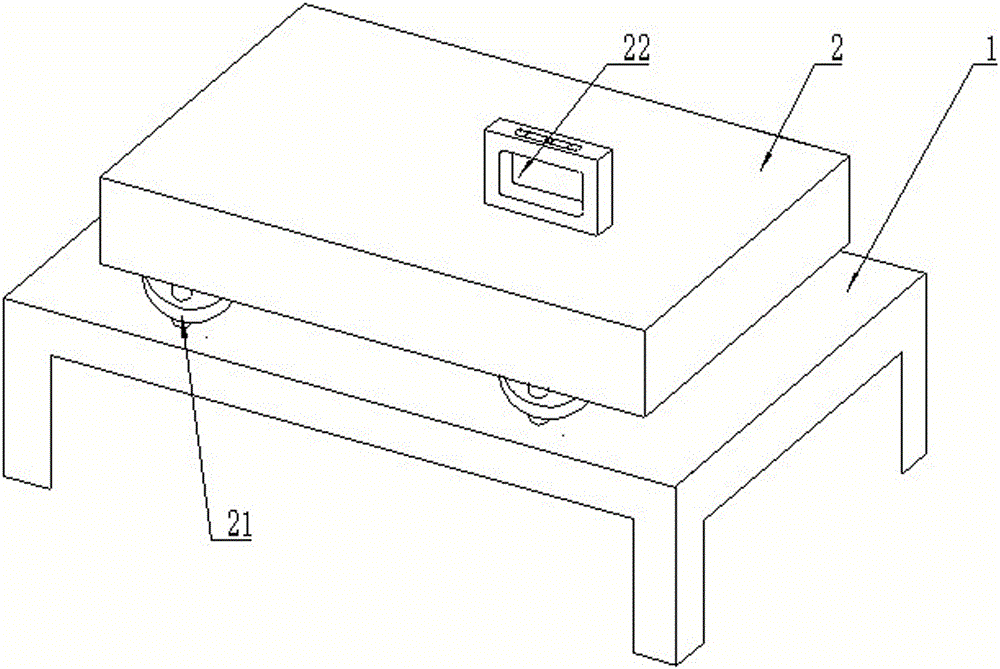

[0024] The verification method for the roll in and out regulation of the textile spinning frame according to the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0025] Depend on figure 1 , figure 2 , image 3 , Figure 4 It can be seen that the method for checking and checking the rollers in and out of the spinning frame of the present invention comprises the following steps:

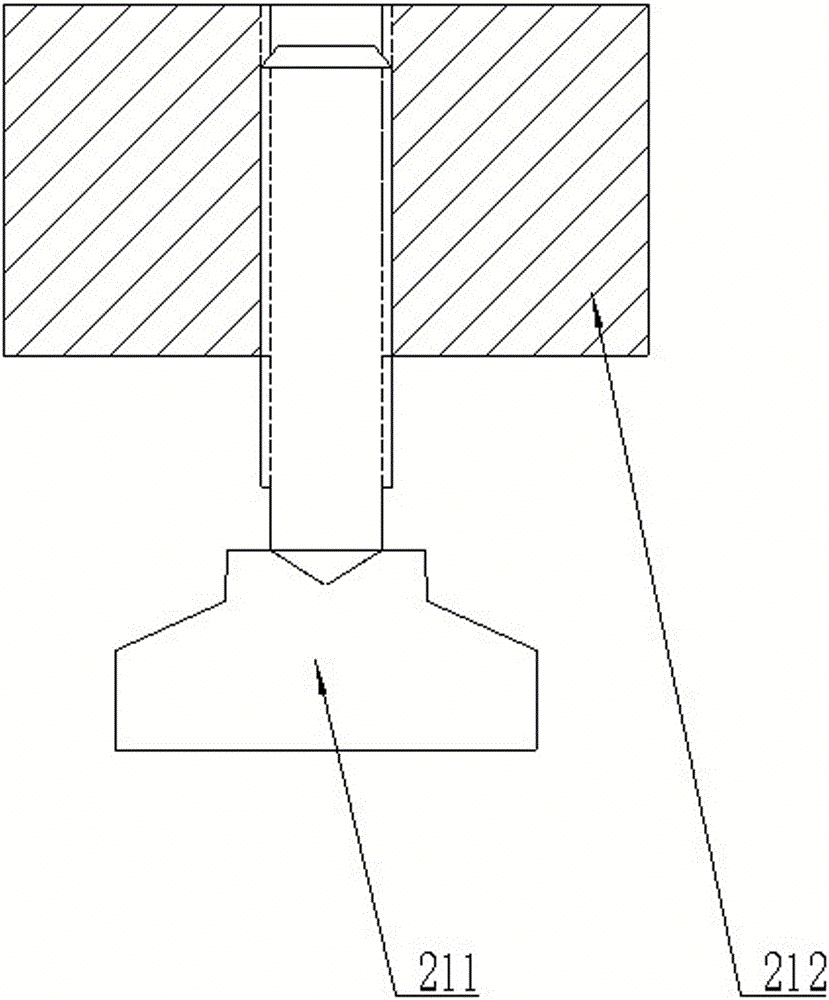

[0026] A adjust the horizontal plane of the detection platform 2 through the frame-type spirit level 22 and the leveling mechanism 21;

[0027] B Place the roller in-and-out gauge 6 on the detection platform 2, so that one scale surface of the square 31 is placed on the plane of the base 62, and the other scale surface is in contact with the cylindrical surface of the standard rod 61, and the distance between the cylindrical surface and the scale surface is observed. gap, and make the gap between the two the smallest. At this time, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com