VDMOS device and manufacturing method thereof

A device and control gate technology, which is applied in the field of VDMOS devices and its manufacturing, can solve the problems of reduced withstand voltage, increased on-resistance, and increased process complexity, and achieve the effect of reducing Miller capacitance and on-resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing, describe technical scheme of the present invention in detail:

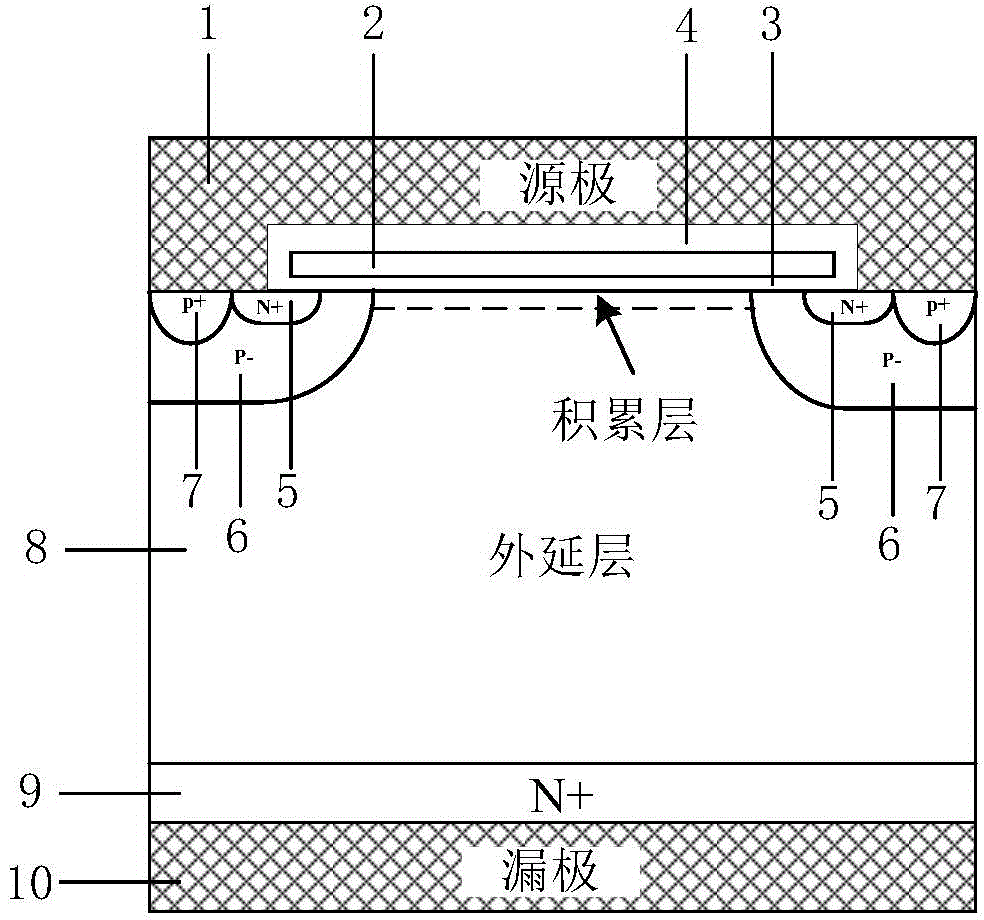

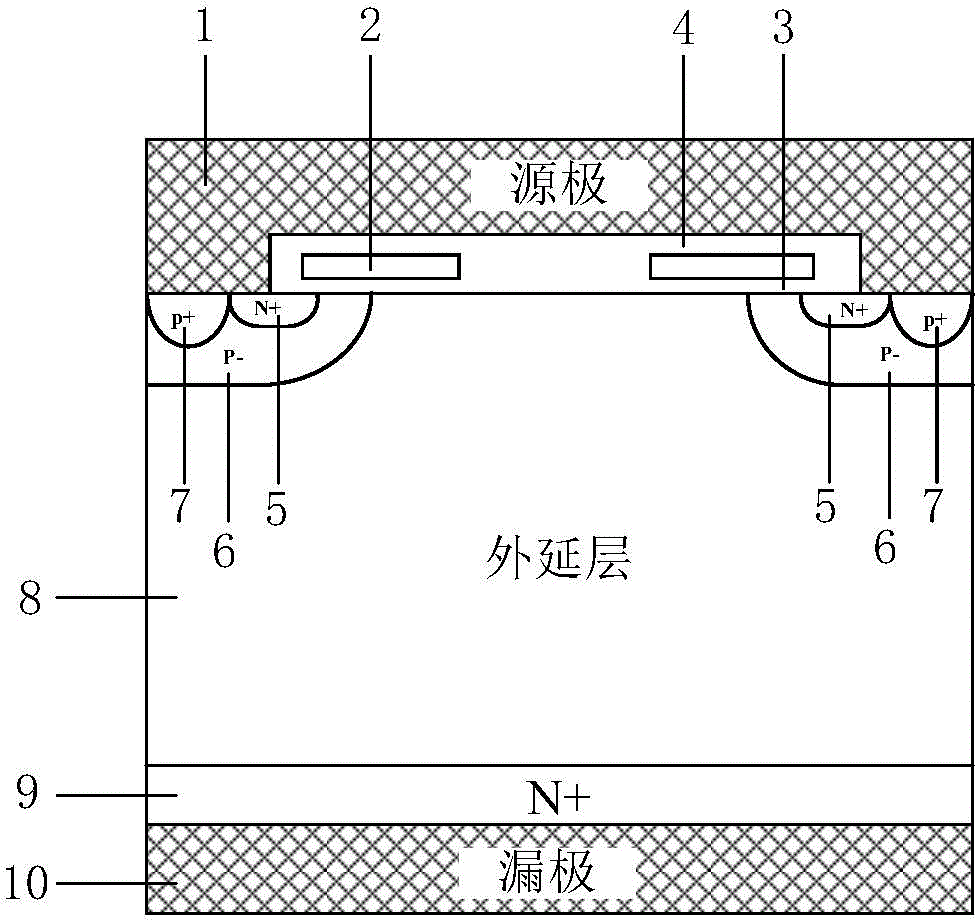

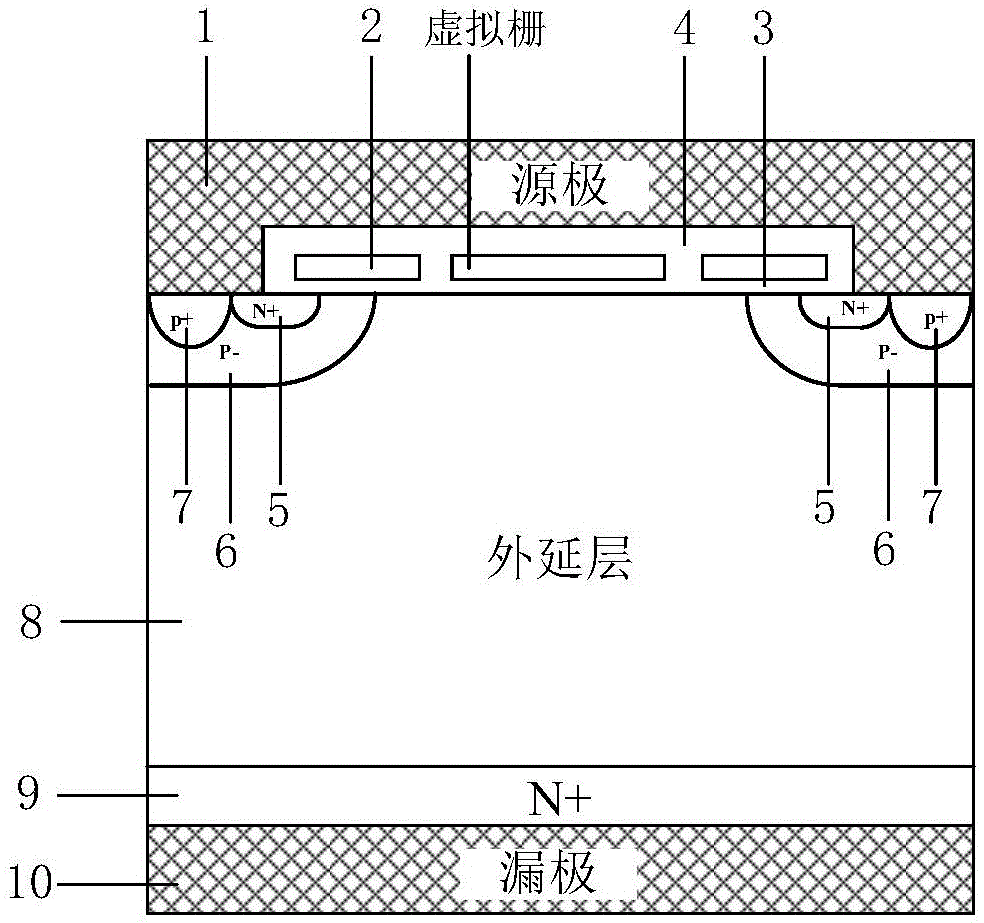

[0039] The present invention proposes a VDMOS device, such as Figure 5 As shown, it includes a semiconductor substrate 9 of the first conductivity type and a semiconductor epitaxial layer 8 of the first conductivity type arranged on the upper surface of the semiconductor substrate 9 of the first conductivity type. The bottom and the drain electrode of the semiconductor substrate 9 of the first conductivity type The metal electrode 10 is connected; the two ends of the upper layer of the first conductivity type semiconductor epitaxial layer 8 have a second conductivity type semiconductor body region 6, and the second conductivity type semiconductor body region 6 has a first conductivity type semiconductor source region 5 and a second conductivity type semiconductor body region. The second conductivity type semiconductor body contact region 7; the first conductivi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap