Aerosol type sunscreen cosmetics

An aerosol and cosmetics technology, applied in the direction of cosmetics, cosmetic preparations, dressing preparations, etc., can solve the problems of unnaturalness, insolubility, and whitening of completion, and achieve good sprayability, high defense effect, and use excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

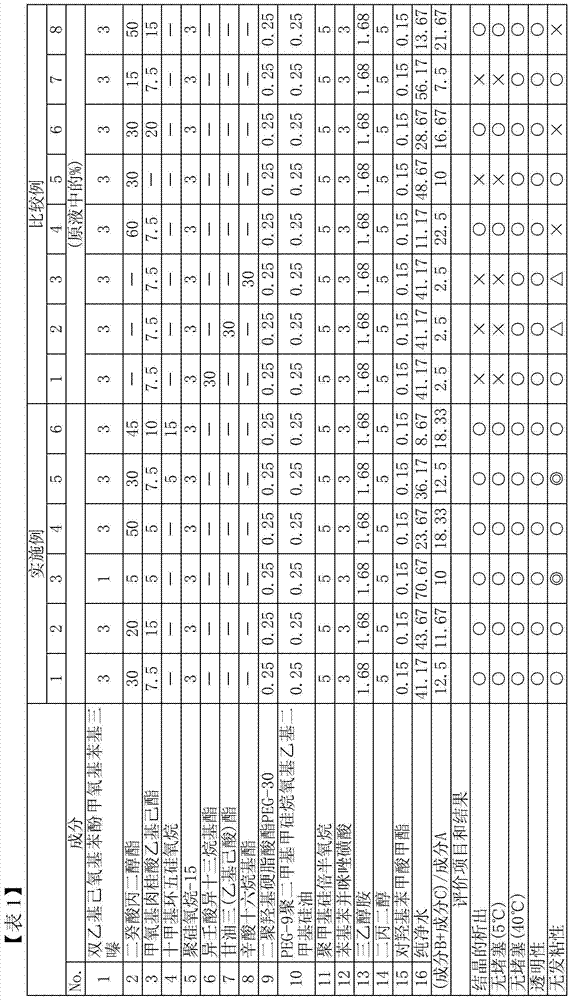

Embodiment 1~6 and comparative example 1~8

[0050] An aerosol-type sunscreen cosmetic was prepared using the composition shown in Table 1 and the following manufacturing method. The obtained cosmetics were evaluated by the following methods, and the results are shown in Table 1 together.

[0051]

[0052] A: Components (1) to (3) and (6) to (8) are heated and dissolved.

[0053] B: After mixing components (4) to (5) and (9) and (10) in A, (11) is uniformly dispersed.

[0054] C: Components (12) to (16) are mixed, added to B and emulsified to obtain a stock solution.

[0055] D: After filling 9 g of the stock solution obtained in C into a transparent glass and aluminum pressure-resistant container, the valve was fixed, and 21 g of LPG was filled into the pressure-resistant container through the valve to obtain an aerosol-type sunscreen cosmetic.

[0056] (Evaluation method 1: precipitation of crystals)

[0057] The aerosol compositions of Examples 1 to 6 and Comparative Examples 1 to 8 were filled into pressure-res...

Embodiment 7

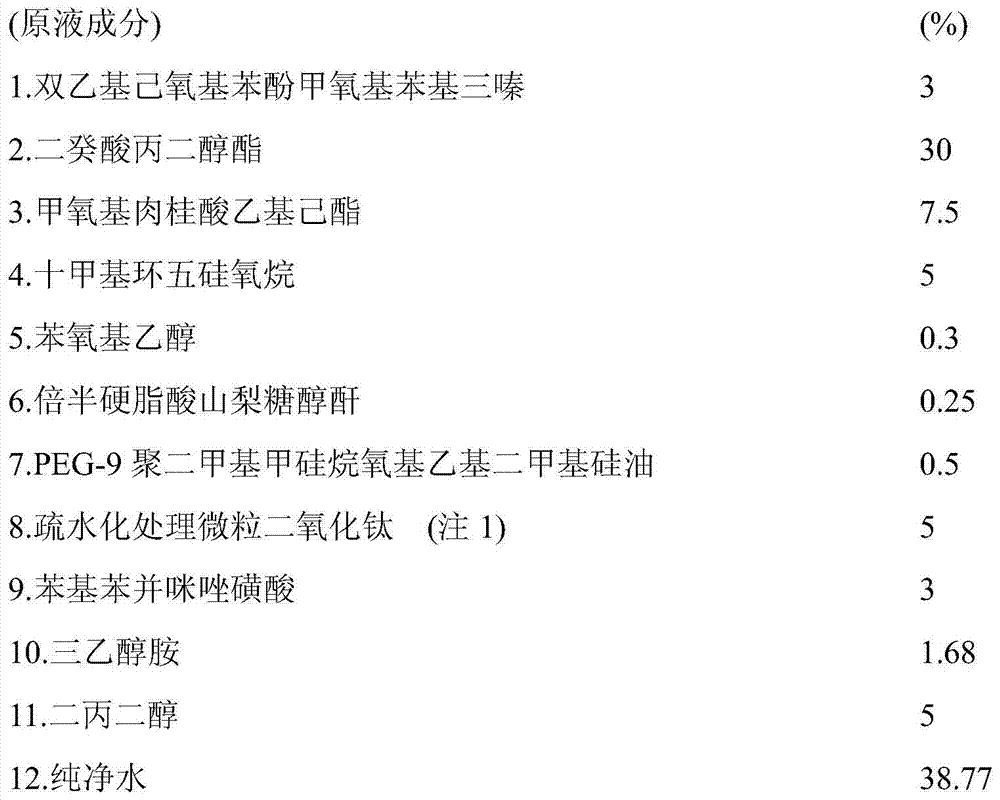

[0092] Example 7: Aerosol sunscreen

[0093]

[0094] (Note 1) Microparticle titanium dioxide MTY-110M3S (manufactured by TAYCA Corporation)

[0095] (Manufacturing method)

[0096] A: Component (8) is dispersed with appropriate amount of component (2) and component (7).

[0097] B: Components (1) to (3) are heated and dissolved.

[0098] C: Components (4) to (6) and B are mixed in A and dispersed uniformly.

[0099] D: Components (9) to (12) are mixed, added to C and emulsified to obtain a stock solution.

[0100] E: After filling 6 g of the stock solution obtained in D into an aluminum pressure-resistant container, the valve was fixed, and 0.15 24 g of LPG was filled into the pressure-resistant container through the valve to obtain an aerosol-type sunscreen cosmetic.

[0101] In Example 7, the adhered part of the aerosol was seen to be whitish immediately after spraying, but immediately became transparent, and the precipitation of bisethylhexyloxyphenol methoxyphenyl ...

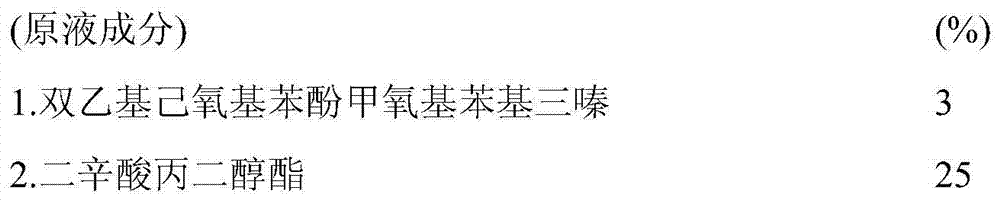

Embodiment 8

[0102] Example 8: Aerosol sunscreen

[0103]

[0104]

[0105] (Note 2) IPSE (manufactured by Nippon Seika Co., Ltd.)

[0106] (Note 3) FINEX-50S-LP2 (manufactured by Sakai Chemical Co., Ltd.)

[0107] (Manufacturing method)

[0108] A: Components (1) to (3) are heated and dissolved.

[0109] B: Components (4) to (10) are mixed with A and dispersed uniformly.

[0110] C: Components (11) to (14) are mixed, added to B, and emulsified.

[0111] D: After filling 9 g of the stock solution obtained in C into an aluminum pressure-resistant container, the valve was fixed, and 21 g of LPG 0.15 was filled into the pressure-resistant container through the valve to obtain an aerosol-type sunscreen cosmetic.

[0112] In Example 8, precipitation of bisethylhexyloxyphenol methoxyphenyl triazine was not confirmed, and it was an aerosol type sunscreen without stickiness in terms of touch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com