High-efficiency classification thickener for tailings slurry

A technology of concentrator and material classification, applied in separation method, sedimentation separation, feeding/discharging device of sedimentation tank, etc., can solve the problems of poor solid-liquid separation effect, difficult to eliminate, equipment paralysis, etc. The effect of good effect, fast discharging speed and low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

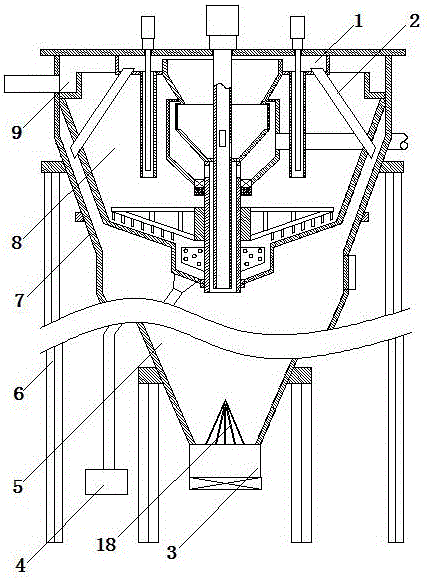

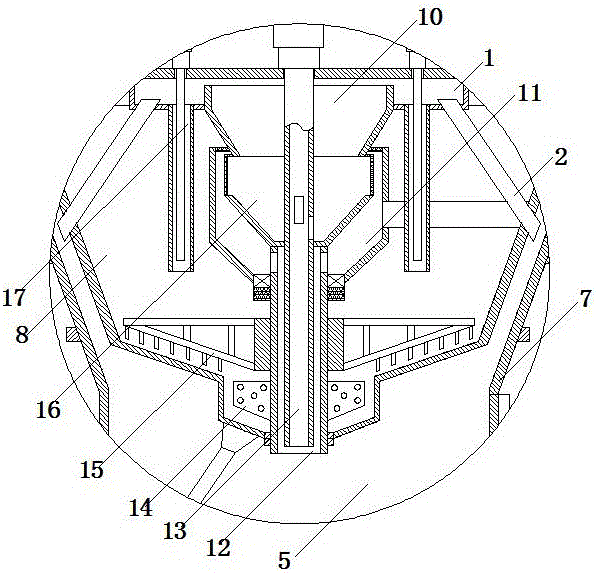

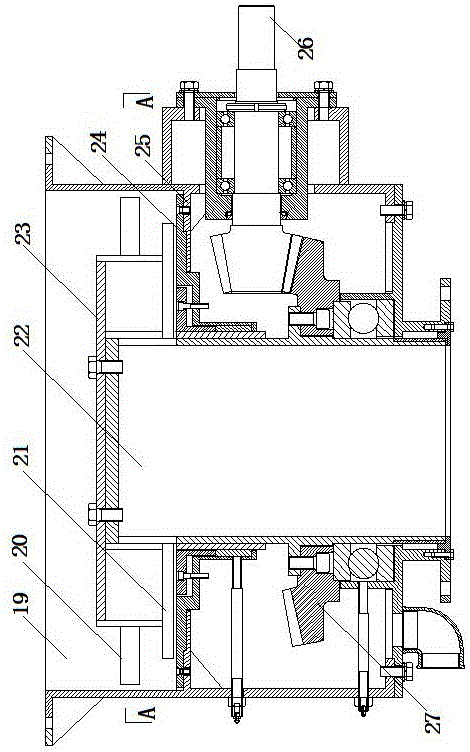

[0038] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the tailings slurry high-efficiency classification concentrator of the present invention includes a support frame 6, a hopper 7 placed on the support frame 6, a material classification device, a stirring device, a return pipe 2, an overflow tank 9 and a discharge device 3 . The inside of the hopper 7 is divided into a classification chamber 8 and a material storage chamber 5 by a partition. A discharge port is provided at the bottom of the material storage chamber 5 . The material classifying device is placed in the classifying chamber 8 , and the material classifying device includes a primary material chamber 11 , a secondary material chamber 16 , a drop pressure chamber 10 and a circulation disc 1 . The primary material chamber 11 communicates with the material inlet pipe. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com