Water washing system for water washing robot of substation

A water flushing and robotic technology, applied in the field of water flushing systems, can solve the problems of water flushing devices not equipped with pure water preparation devices, occupy a large area, and be difficult to maintain, so as to improve flushing efficiency and automation level, and solve the problem of occupied area Effect of oversized, optimized structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the drawings and embodiments.

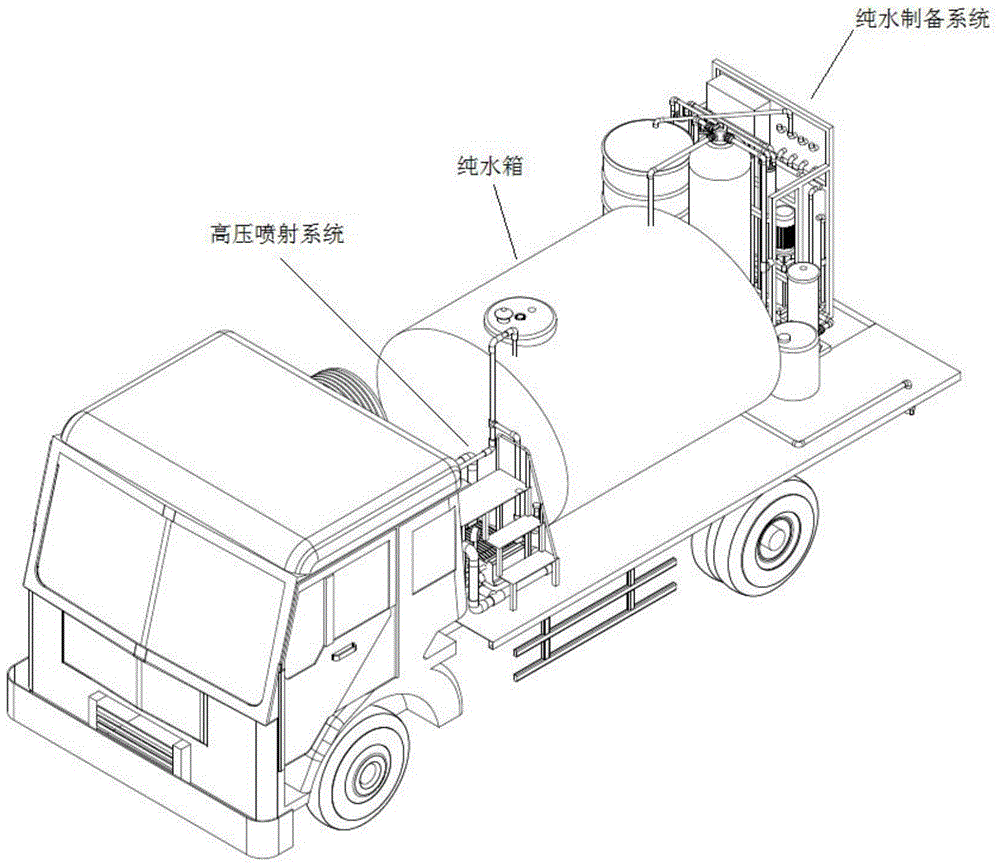

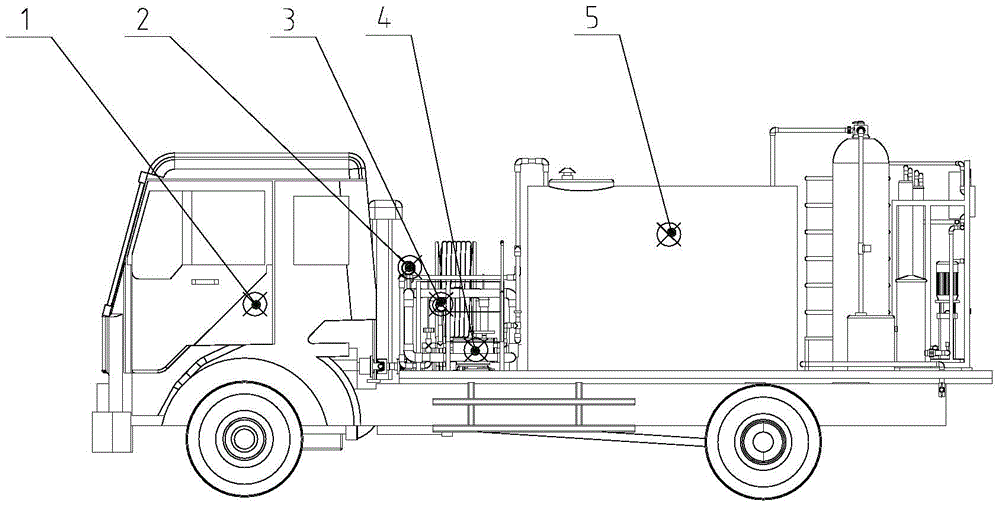

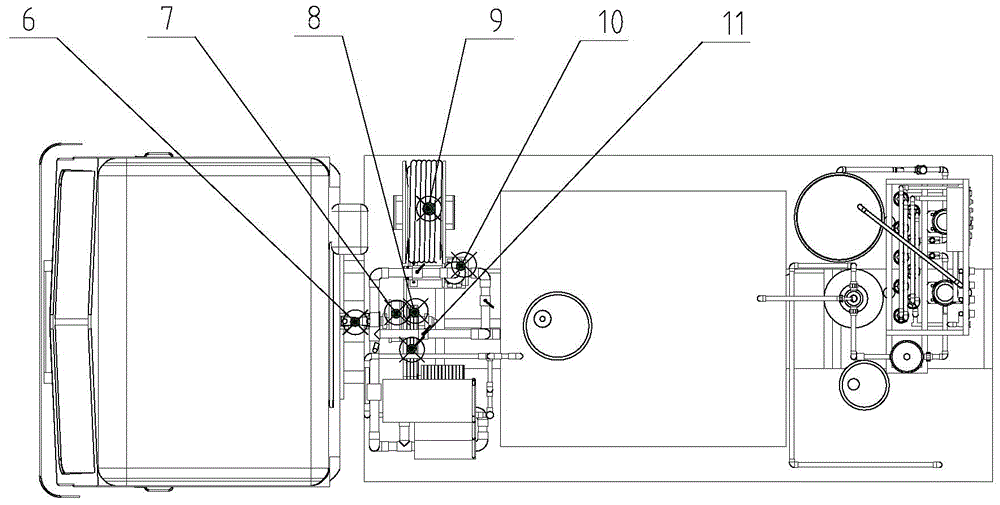

[0038] A water washing system used for water washing robots in substations, such as figure 1 Shown, including: pure water preparation system, high pressure injection system and electric control system; pure water preparation system is connected with high pressure injection system, electric control system is connected with pure water preparation system and high pressure injection system respectively; pure water preparation system is set in mobile On the side of the chassis away from the front of the car, the high-pressure injection system is arranged on the side close to the front of the car, and the pure water preparation system and the high-pressure injection system are connected by a pure water tank. The high-pressure injection system is connected to the hose reel, and a 60-meter water pipe is wound on it. The high-pressure water from the water pump is mainly delivere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com