Mobile self-supply substation live water washing robot system

A robotic system and technology of electrified water, applied in manipulators, program-controlled manipulators, chemical instruments and methods, etc., can solve the problems of potential safety hazards, high labor intensity and low level of automation in flushing operations, and meet the requirements of water flushing on-site operations. , to meet the job requirements, the effect of fast preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0043] A mobile self-supplied substation charged water washing robot system, comprising: a water washing system and a charged water washing robot, the water washing system includes a pure water preparation system and a high-pressure injection system; the pure water preparation system is connected to the high-pressure injection system , The high-pressure injection system is connected to the high-pressure live water washing robot through a high-pressure pipeline; the high-pressure water from the hose reel is directly connected to the high-pressure water inlet pipe of the robot through a quick-change joint.

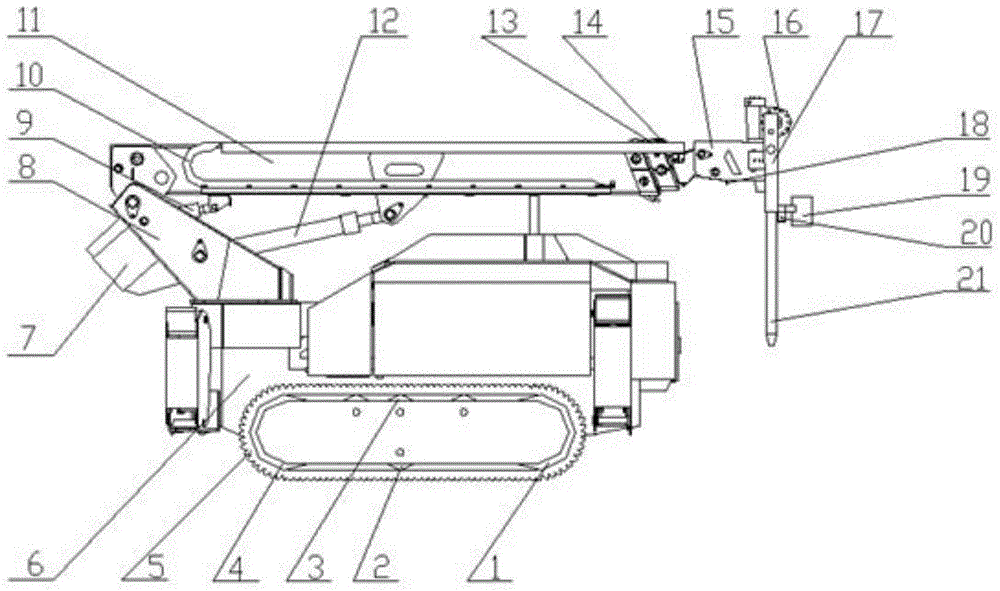

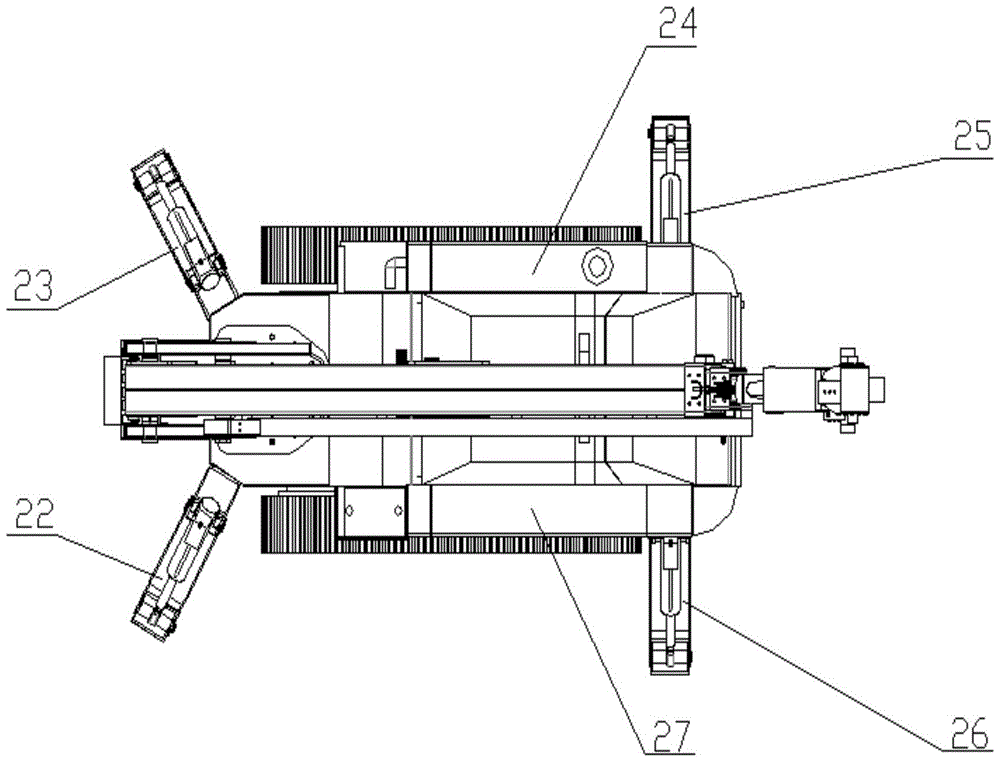

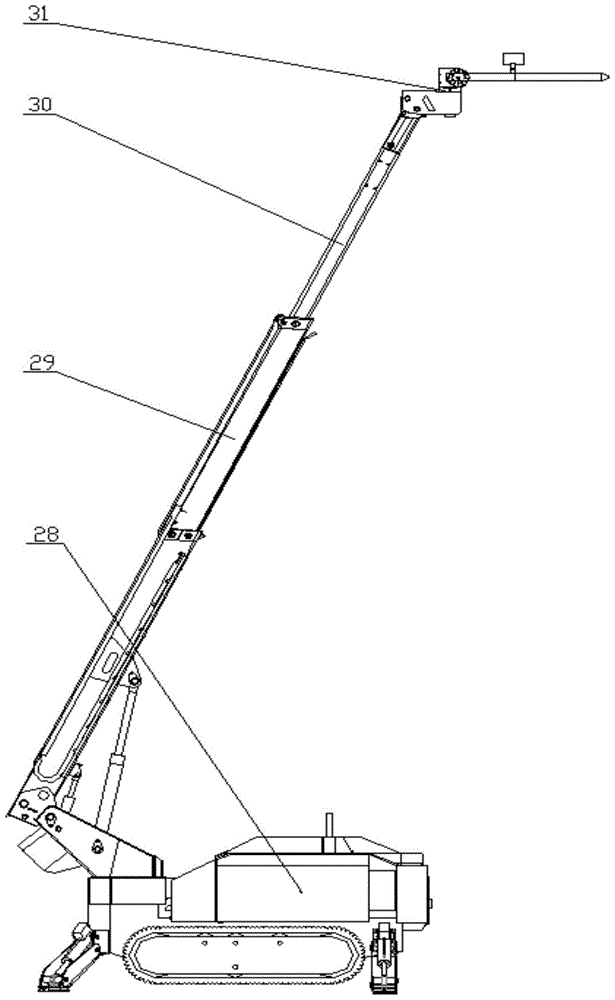

[0044] The schematic diagram of the structure of the charged water washing robot is as follows: Figure 1-3 As shown, the main body is composed of a mechanical body and a remote control device. Among them, the mechanical body is mainly composed of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com