Automatic spin-riveting machine

A technology for a rotary riveting machine and a riveting machine base is applied in the field of machinery manufacturing equipment, which can solve the problems of wasting human resources, increasing production costs, and low work efficiency, and achieves the effects of reducing production costs, improving work efficiency, and designing scientifically.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

[0043] The structures, connections and methods not described in detail in the present invention can be understood as common knowledge in the field.

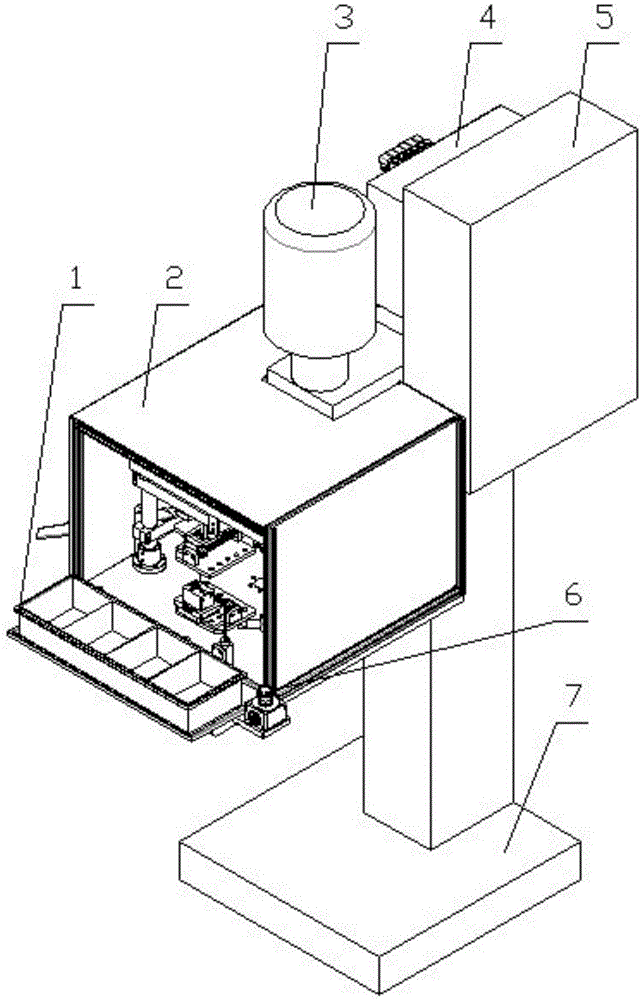

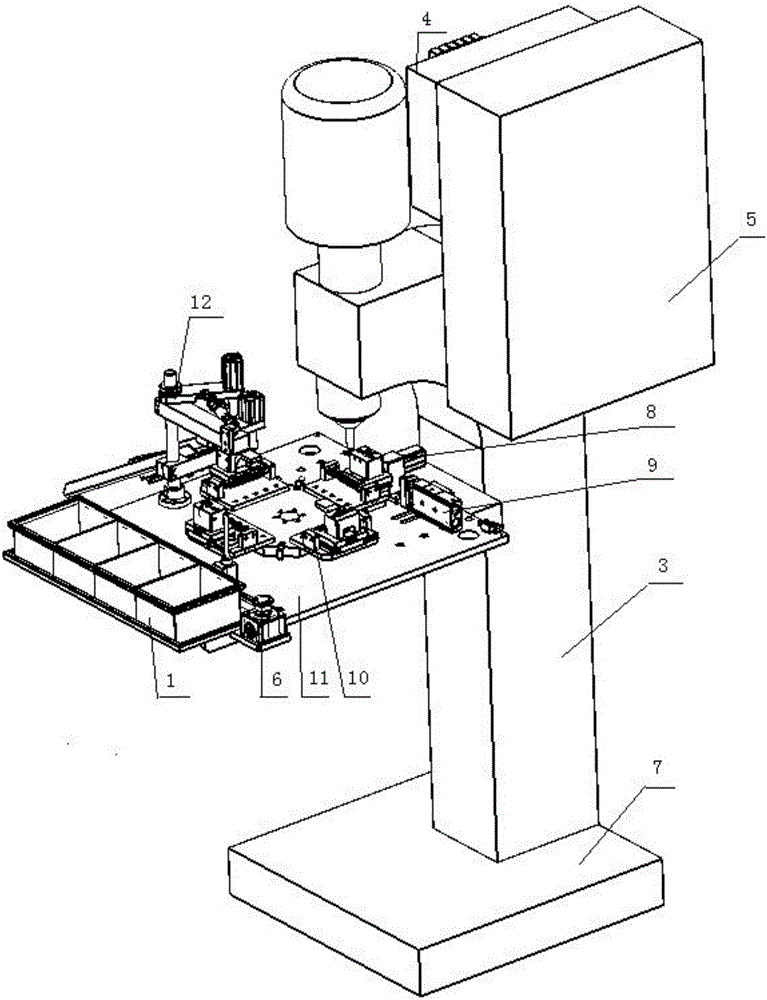

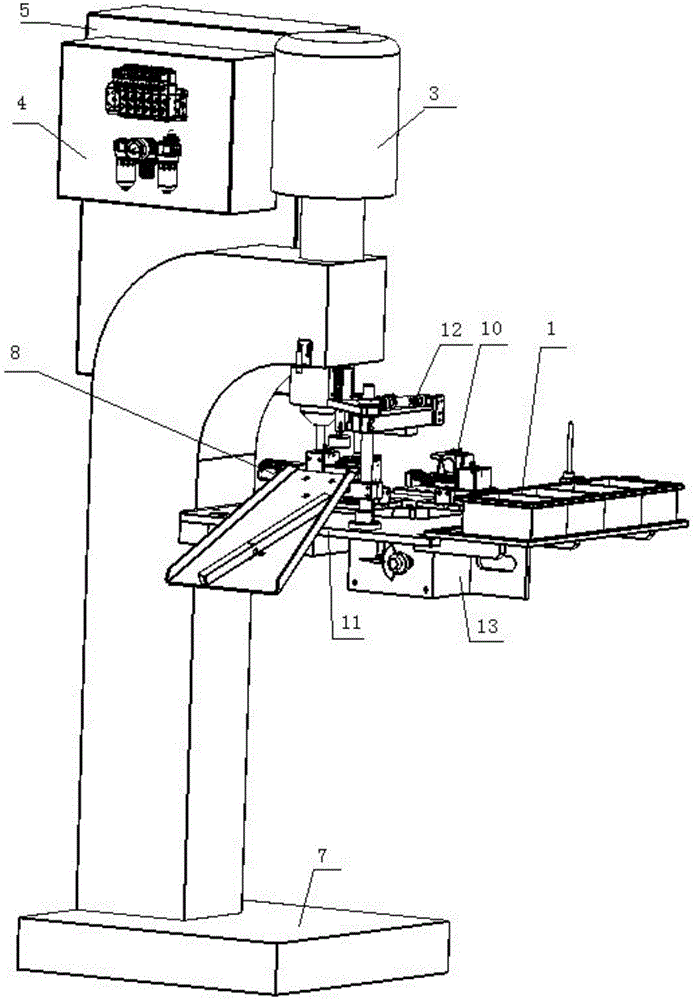

[0044] An automatic riveting machine, such as figure 1 , figure 2 and image 3 As shown, the riveting machine includes a riveting machine body 3, an electric control cabinet 5, a pneumatic cabinet 4, a divider 13, a riveting machine base 7, a riveting machine base 11, a turntable clamp 10, a translation clamp 9, and a clamp lock pin Mechanism 8 and blanking mechanism 12, the bottom of the riveting machine body is connected with the riveting machine base, the middle part of the riveting machine body is vertically connected with the riveting machine base arranged in the horizontal direction, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com