Tobacco conveying device capable of realizing interval uniform-velocity conveying

A conveying device and tobacco leaf technology, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve problems such as fatigue-prone tobacco leaf accumulation, accidents, manual unloading workers, etc., to reduce load, ensure safety, and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

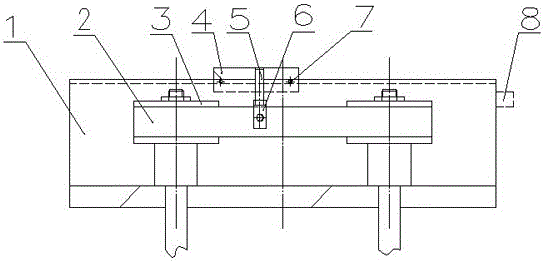

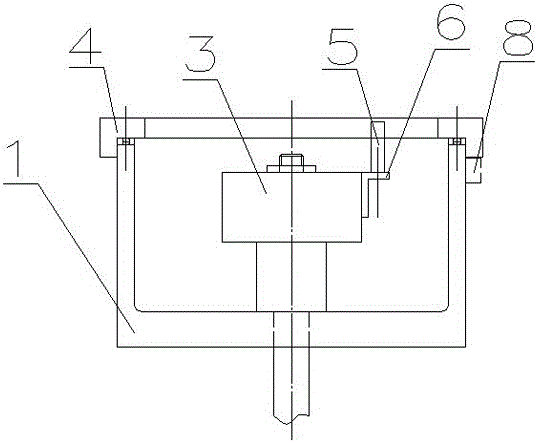

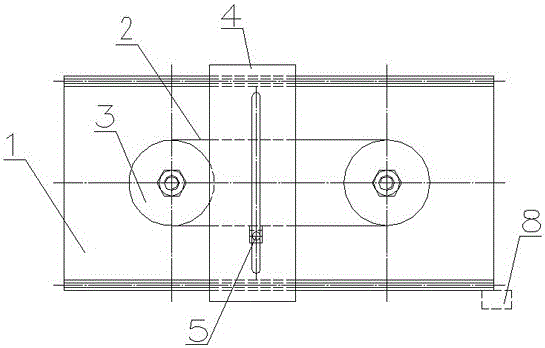

[0018] figure 1 , figure 2 with image 3 As shown, the specific implementation is as follows:

[0019] A tobacco leaf conveying device capable of intermittent and uniform conveying, comprising a support 1, a conveying belt 2, a conveying pulley 3, a connector 6, a pin shaft 5 and a tobacco leaf conveying platform 4, the conveying pulley 3 is mounted on the support 1 and driven The shaft drives it to rotate, the conveyor belt 2 is set on the conveyor pulley 3, the tobacco leaf conveying platform 4 is slidably arranged on the support 1, and a through groove is also provided on the tobacco leaf conveying platform 4, and the length direction of the through groove is the same as that of the tobacco leaf conveying platform 4. The direction of movement is vertical, one end of the pin shaft 5 is inserted into the through groove, and the other end is fixed on the conveyor belt 2 through the connector 6, so that the movement of the conveyor belt 2 drives the tobacco leaf conveyor tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com