A detachable anti-loosening bolt or screw assembly

A technology for screw assemblies and anti-loosening bolts, applied in the directions of screws, bolts, threaded fasteners, etc., can solve the problem of inconvenient disassembly of the connection structure, and achieve the effects of simple structure, reasonable structure design, and convenient disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

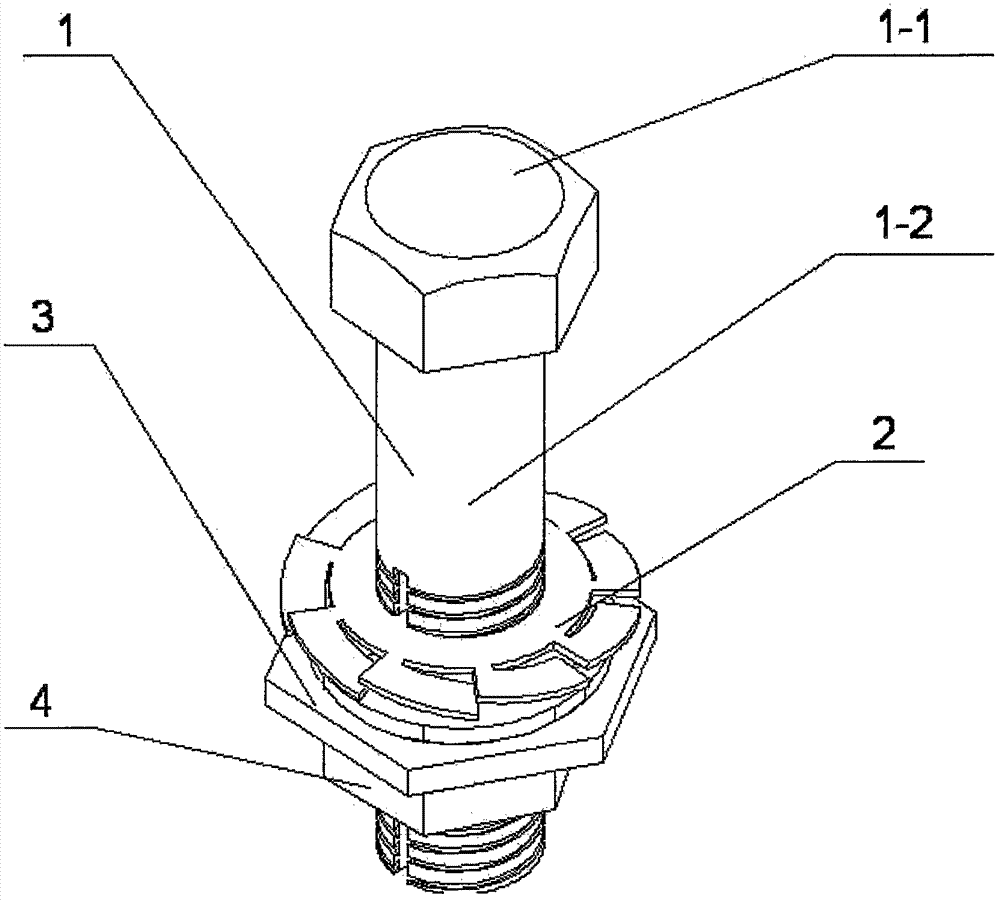

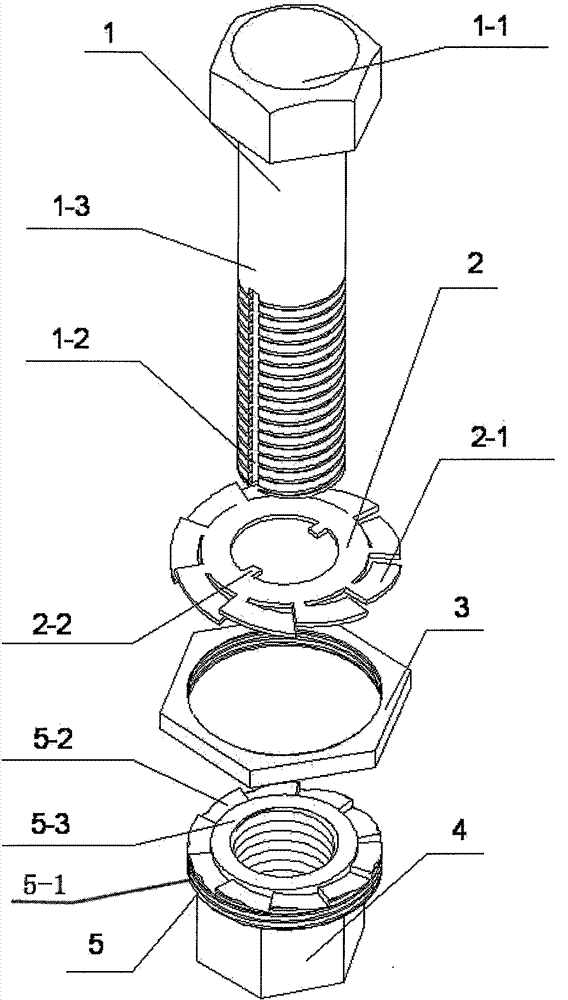

[0020] like Figure 1-3 As shown, a detachable anti-loosening bolt assembly includes a bolt 1, a ratchet washer 2, a pressure washer nut 3 and a ratchet nut 4 that cooperate with each other; the bolt 1 includes a nut 1-1 and a screw 1-3 , the screw 1-2 is provided with several grooves 1-2 along the axial direction; The external thread of the bolt 1 is matched with the internal thread of the ratchet nut 4 .

[0021] The pawl washer 2 is annular, and a plurality of elastic pawls 2-1 are arranged on the end surface of the pawl washer 2; -2 is used to prevent the rotation of the pawl spacer 2;

[0022] The ratchet nut 4 is provided with a radial annular flange 5 at one end close to the nut 1-1 of the bolt 1; the annular flange 5 and the ratchet nut are integrally manufactured, and the outer diameter of the annular flange 5 is larger than outer diameter. The annular flange 5 is provided with a ratchet structure 5-2 on the end face close to the bolt and nut 1-1;

[0023] The qu...

Embodiment 2

[0028] like Figure 4-5 As shown, this embodiment is basically the same as Embodiment 1, the difference is:

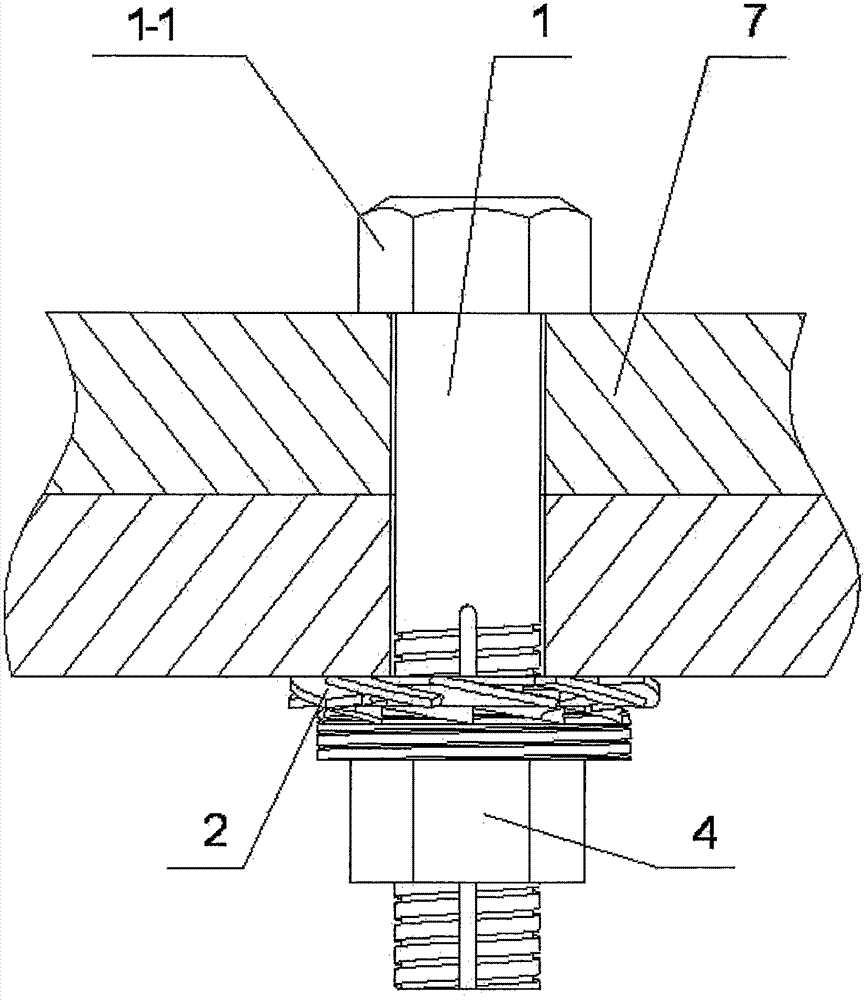

[0029] A detachable anti-loosening bolt assembly, which includes a bolt 1, a nut 8, a pawl washer 2, and a pressure washer nut 3 that cooperate with each other; The flange 5; the nut 6 is a ratchet nut; the outer diameter of the annular flange 5 is larger than the outer diameter of the nut 6. The annular flange 5 is provided with a ratchet structure 5-2 on the end face close to the bolt and nut 1-1; There is no groove on bolt 1. The nut 8 is a common nut and is matched with the bolt 1 .

[0030] The pawl washer 2 is provided with a plurality of protrusions 2-3 on one end surface close to the fastener 7, and the protrusions 2-3 cooperate with several concave holes on the end surface of the fastener 7 to prevent the pawl. Spacer 2 turns. The surface of the fastener 7 in contact with the nut 8 is provided with an insertion groove 7-1, which has the same shape as the ...

Embodiment 3

[0032] like Image 6 As shown, this embodiment is basically the same as Embodiment 2, and the difference is:

[0033] A detachable anti-loosening screw assembly, which includes a ratchet washer 2, a pressure washer nut 3, and a screw 1a; the screw 1a is provided with an annular flange 5 at one end close to the fastener, and the fastener 7 has a thread hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com