Aluminum-plastic composite tube quick joint

An aluminum-plastic composite pipe, fast technology, applied in the field of pipe joints, can solve the problems of joint leakage, slow construction speed on site, poor corrosion resistance, etc., and achieve the effects of preventing water pipe leakage, long service life, and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below by means of specific embodiments:

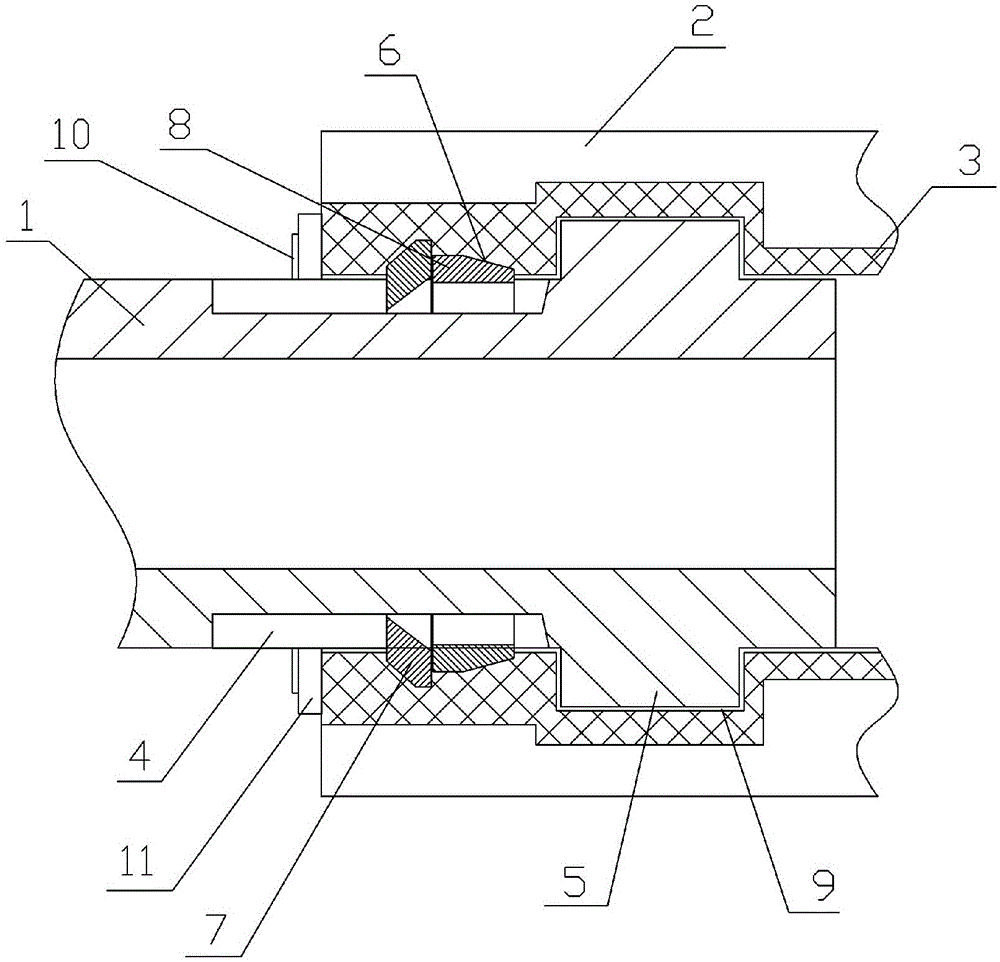

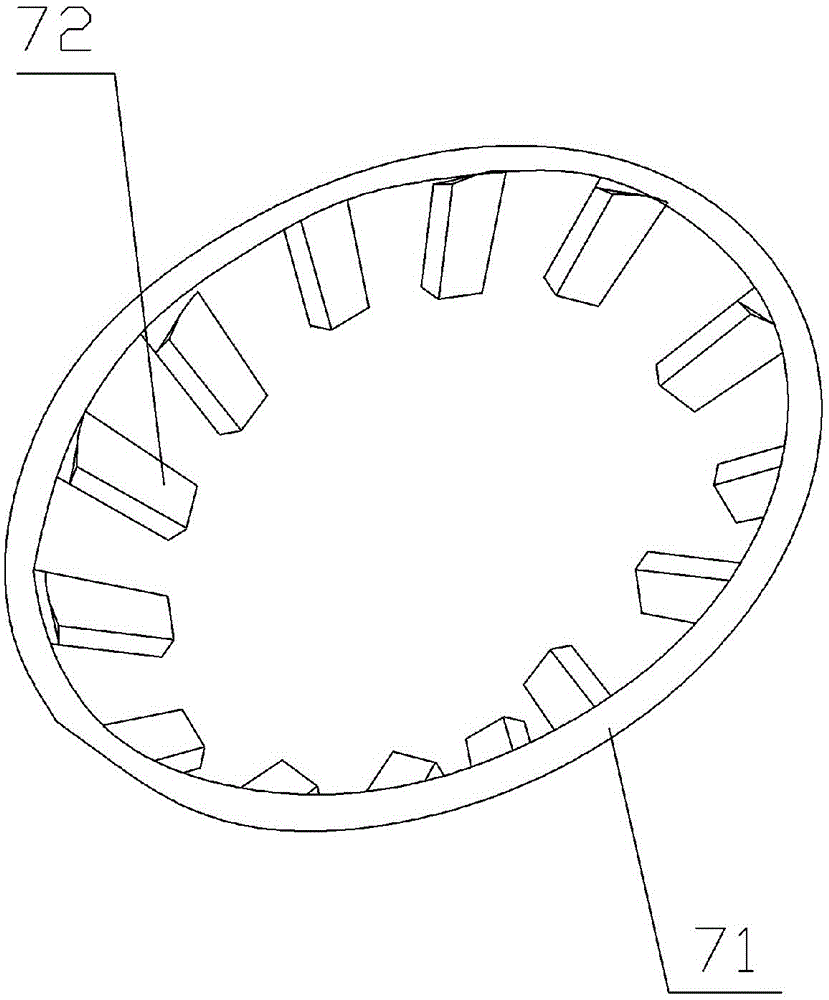

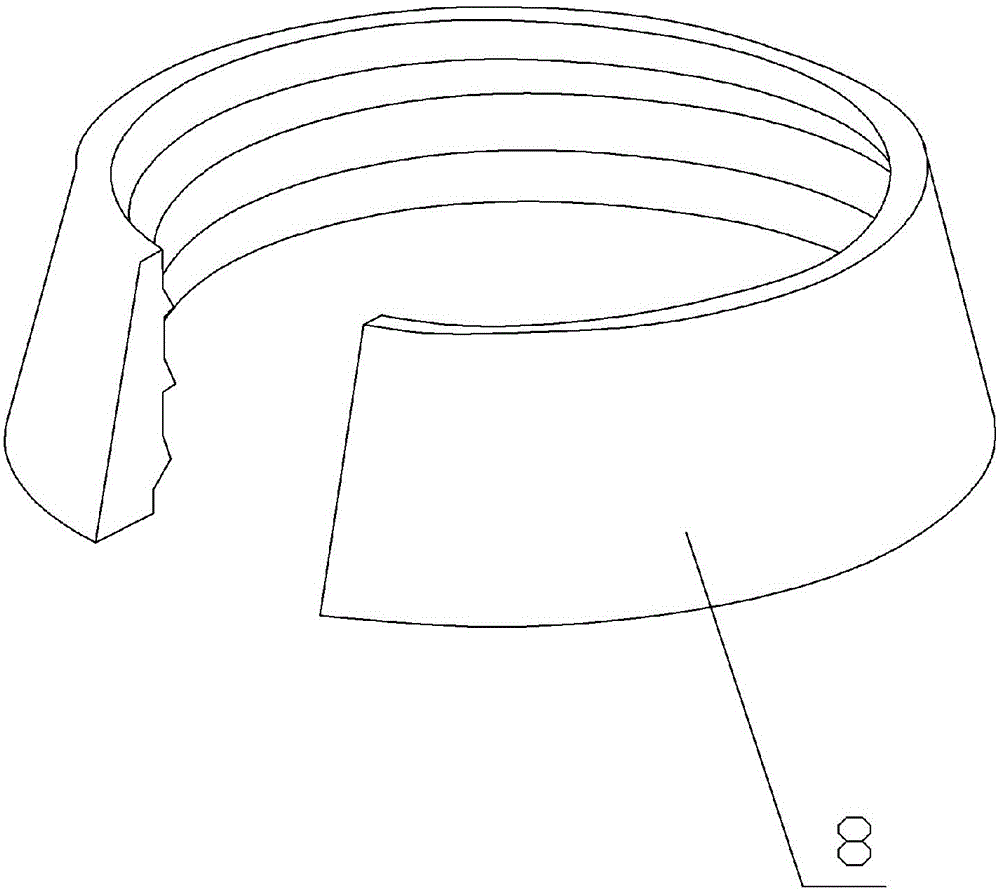

[0013] The reference signs in the drawings of the specification include: sleeve 1, inner steel strip layer 2, glass fiber plastic layer 3, pipe slot 4, outer flange 5, undercut groove 6, clamping piece 7, snap ring 71, Undercut anti-slip teeth 72, locking ring 8, inner groove 9, water sealing ring 10, sealing ring 11.

[0014] The embodiment is basically as attached figure 1 , image 3 Shown: Aluminum-plastic composite pipe quick connector, including sleeve 1 and connecting parts, the connecting parts include an integrally formed inner steel belt layer 2 and glass fiber plastic layer 3 from outside to inside, and the sleeve 1 is provided with a pipe insert Groove 4 and the outward flange 5, the pipe slot 4 is provided with an undercut groove 6, and the bottom of the pipe slot 4 is arranged in turn along the bottom of the pipe slot 4 to the direction of the notch in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com