Manufacturing process of novel tube-sheet evaporator

A production process, tube-sheet technology, applied in evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problems of high resistance to refrigerant operation, wear and tear, slow return speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

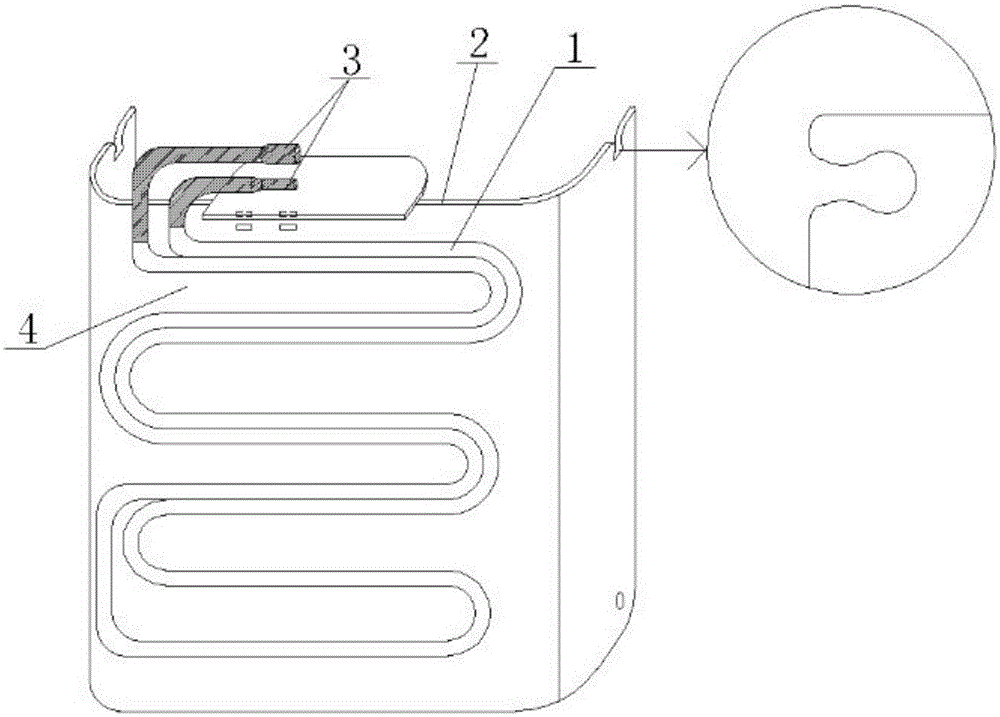

[0013] See the attached picture: a new type of tube-sheet evaporator manufacturing process, the aluminum tube coil is straightened and cut into a specific length of straight material, bent into a serpentine aluminum tube 1 with 14 corners, and then flattened Forming, while ensuring that the specific size of the serpentine aluminum tube 1 end is not crushed, the height of the aluminum tube in the flattened area is controlled at 0.6 to 0.68 times the original diameter, and then a section of copper transition is welded on the end of the serpentine aluminum tube 1 The tube 3 is coated with a vulcanized film 4 on the surface of the sheared aluminum plate 2, vulcanized the flattened serpentine aluminum tube 1 and the aluminum plate 2 covered with a vulcanized film, and folded the vulcanized product into U Type, U-shaped products are sprayed, cured and dried to make a new tube-sheet evaporator. Preferably, the specification of the aluminum tube is φ6.5×0.8mm, φ7×0.75mm, φ7.5×0.8mm, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com