Aluminum electrolytic capacitors

A technology of aluminum electrolytic capacitors and electrolytic paper, which is applied to capacitor parts, capacitor casings/packages, etc., can solve problems such as large impedance, fuse failure of guide pins or guide foils, etc., to reduce contact resistance and improve high ripple resistance Current capacity, the effect of improving the current carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

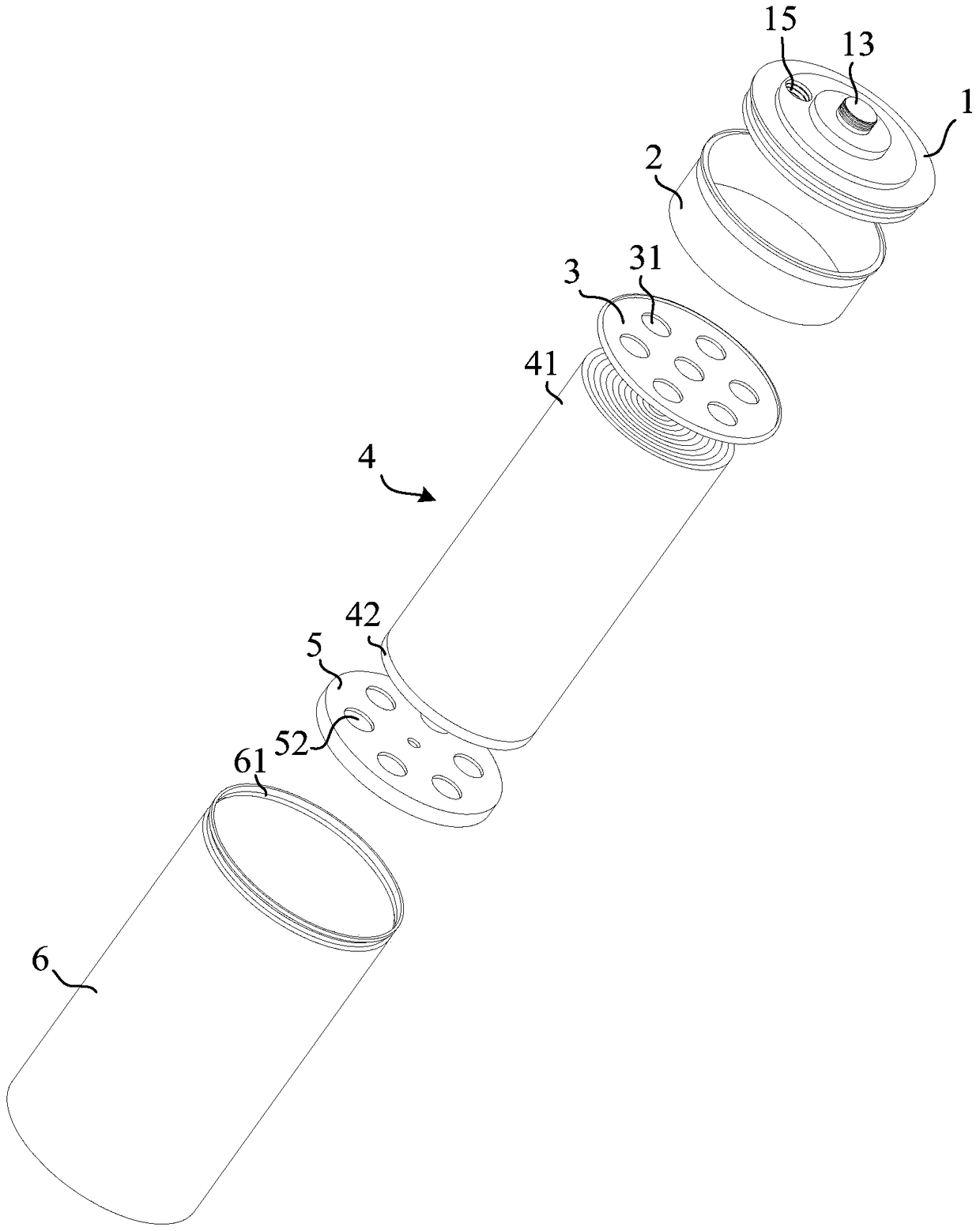

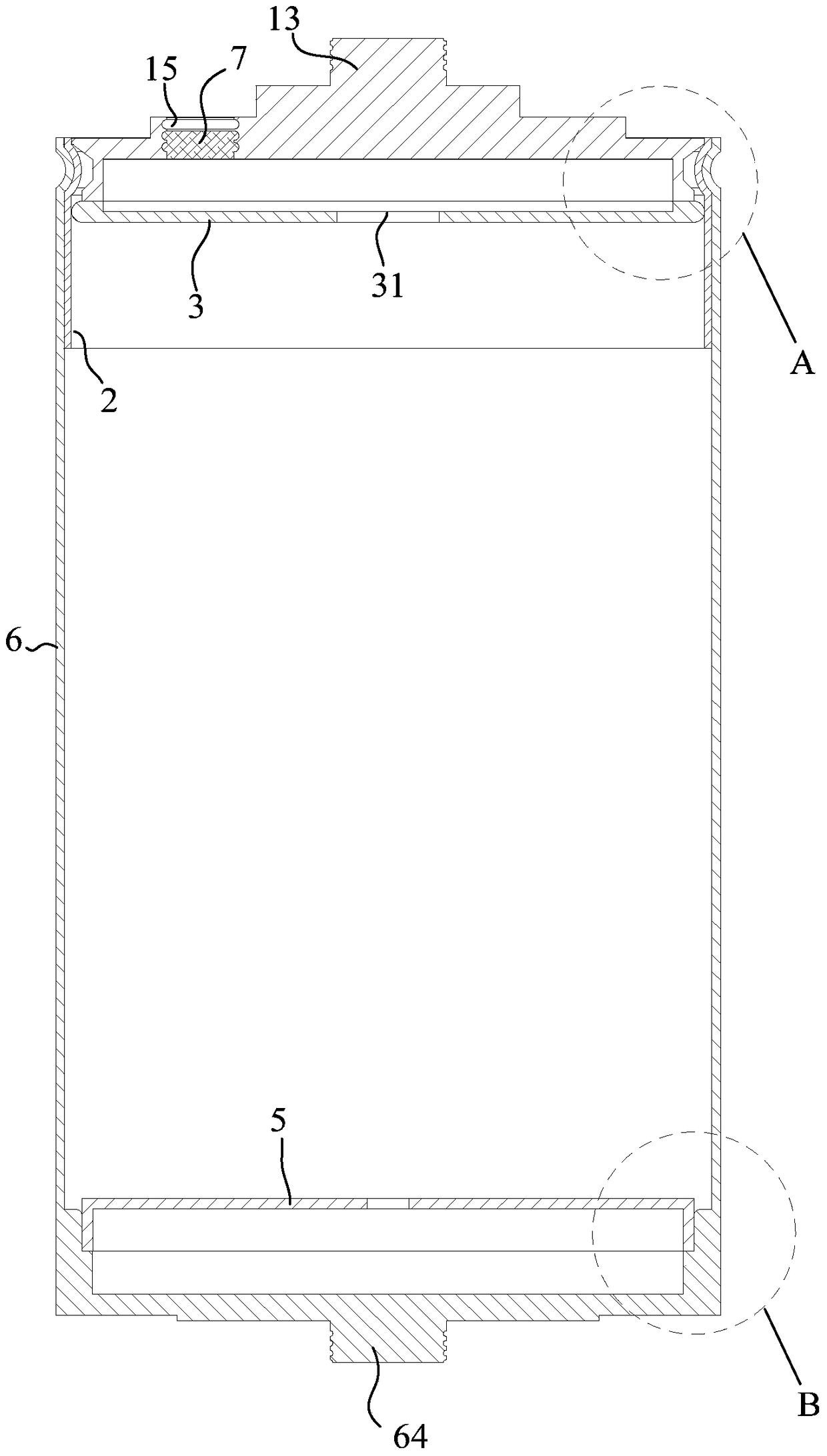

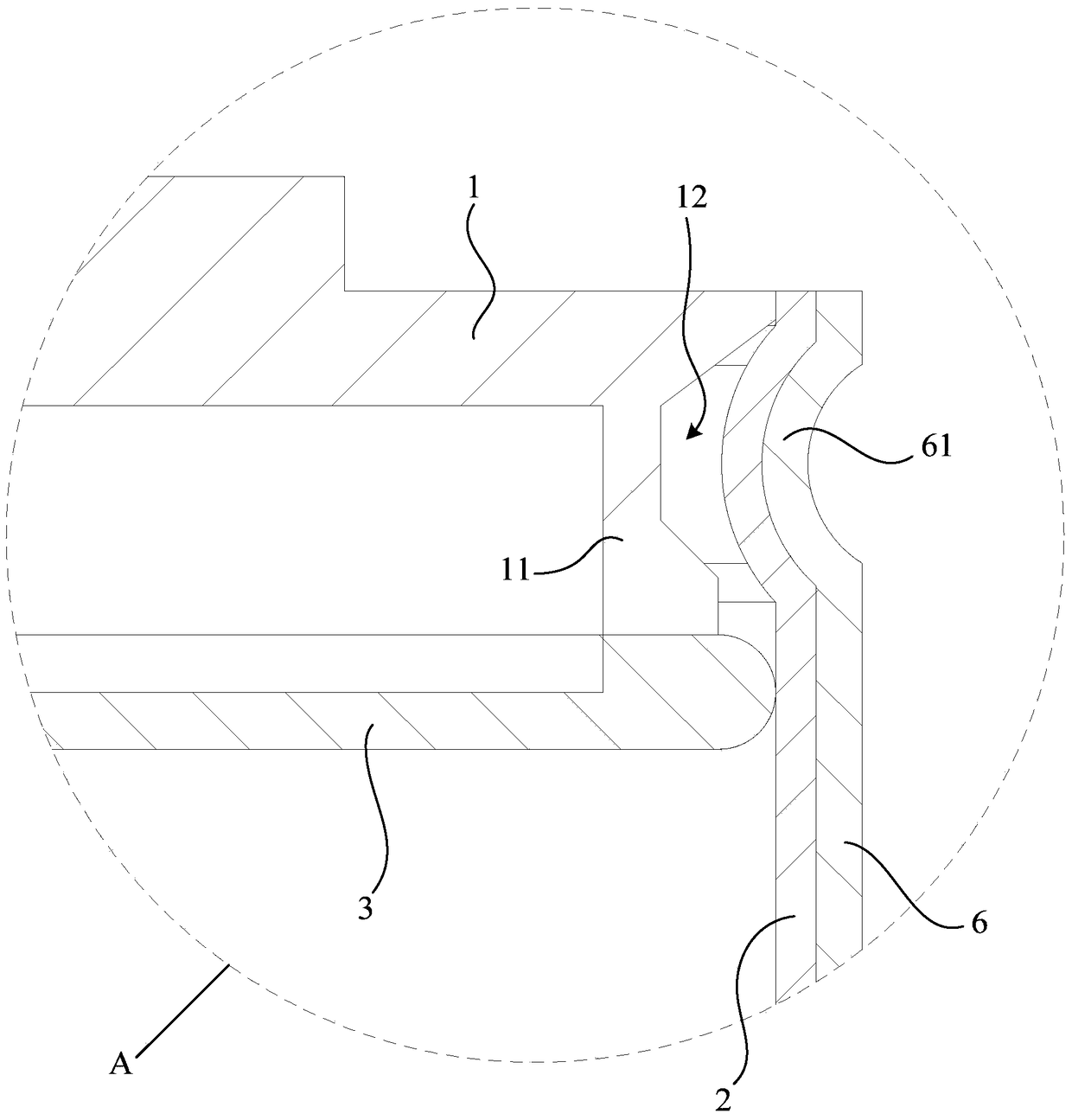

[0023] The aluminum electrolytic capacitor proposed by the present invention, please refer to Figure 1 to Figure 4 , In one embodiment, the aluminum electrolytic capacitor includes a top cover 1 , an insulating sleeve 2 , an upper collector plate 3 , a core set 4 , a lower collector plate 5 , and a case 6 . The core set 4 includes positive aluminum foil 41 , electrolytic paper (not shown) and negative aluminum foil 42 . The electrolytic paper is sandwiched between the positive aluminum foil 41 and the negative aluminum foil 42 , and is wound together with the positive aluminum foil 41 and the negative aluminum foil 42 to form the core group 4 . The shell 6 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com