External stator magnetic pole parallel type hybrid excitation composite motor

A hybrid excitation and composite motor technology, applied in the direction of electrical components, electromechanical devices, etc., can solve the problem of small output torque, achieve the effect of improving overload capacity, realizing brushless, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

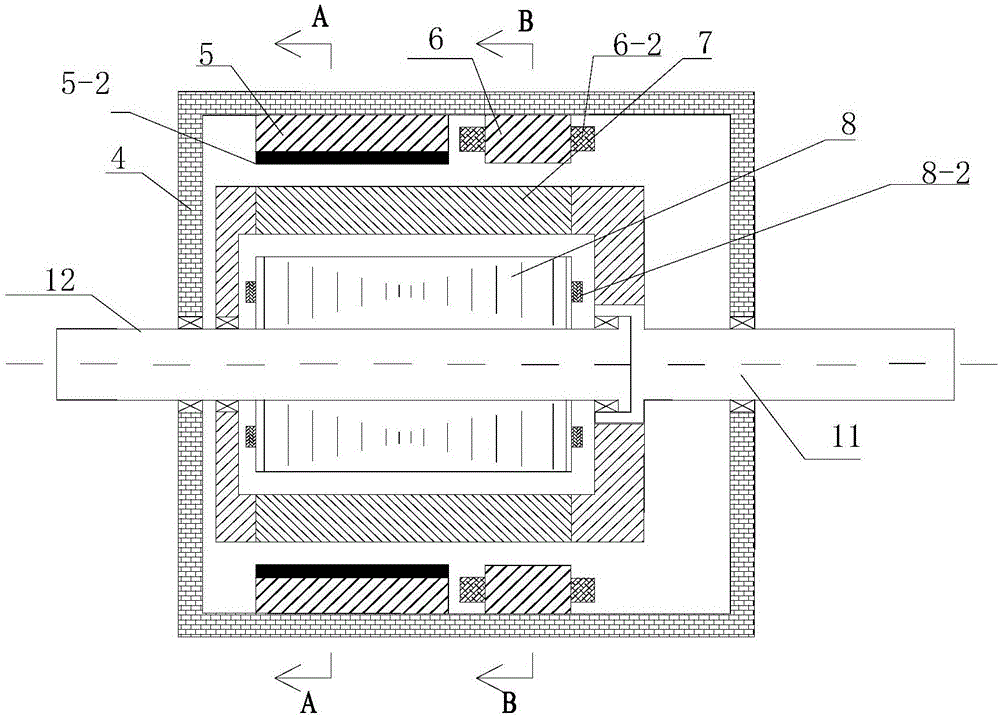

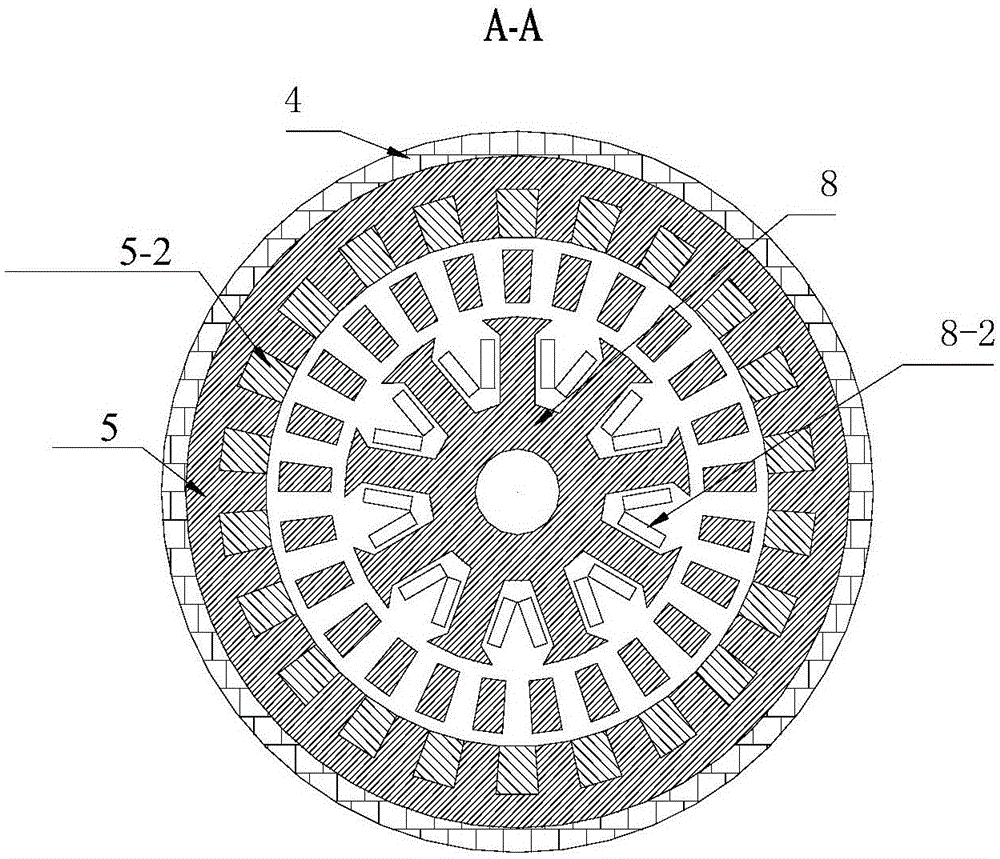

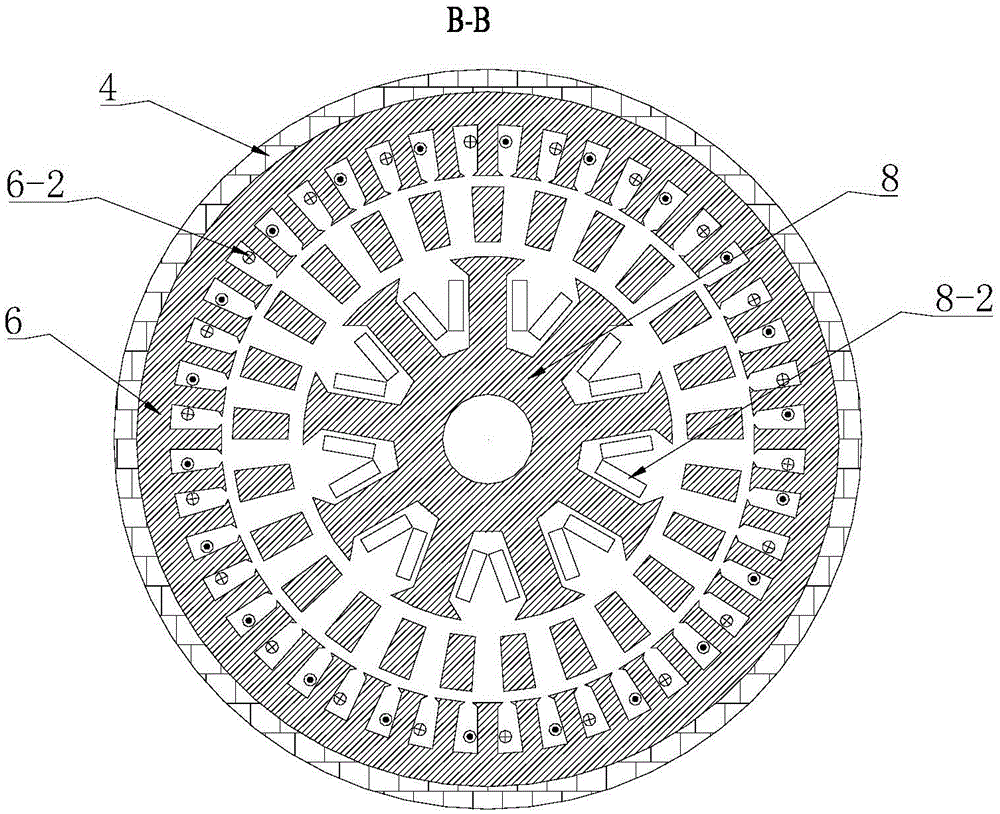

[0019] Specific implementation mode 1. Combination Figure 1 to Figure 3 Describe this specific embodiment, the outer stator magnetic pole parallel type hybrid excitation composite motor described in this specific embodiment includes an inner stator 8, an outer stator and a magnetic flux ring rotor 7, and the magnetic flux ring rotor 7 is located between the inner stator 8 and the outer stator , and fixed on one end of the output shaft 11 of the magnetic ring rotor through a bracket, the other end of the output shaft 11 of the magnetic ring rotor passes through the right end cover of the motor casing 4, and is connected to it through a bearing for rotation, the magnetic ring The rotor 7 is separated from the inner stator 8 and the outer stator by a radial air gap;

[0020] The inner stator 8 is fixed on the inner stator output shaft 12, and one end of the inner stator output shaft 12 passes through the left end cover of the motor casing 4, and is connected to it in rotation th...

specific Embodiment approach 2

[0028] Embodiment 2. The difference between this embodiment and the outer stator pole-parallel hybrid excitation compound motor described in Embodiment 1 is that both the permanent magnet 5-2 and the excitation winding 6-2 are of C-shaped structure.

[0029] In this embodiment, the permanent magnets 5-2, the outer stator yoke and the outer stator teeth are arranged in a C-shaped structure, and the Halbeck 90° magnetization method is used to cut each permanent magnet into three parts, and the middle part is radially charged. Magnetic, both sides are magnetized in the circumferential direction and a non-magnetic material is inserted between it and the core to reduce magnetic flux leakage and improve the utilization rate of the permanent magnet, or radial magnetization is used, such as Figure 8 and Figure 9 shown.

specific Embodiment approach 3

[0030] Specific Embodiment 3. The difference between this specific embodiment and the outer stator pole-parallel hybrid excitation composite motor described in specific embodiment 1 is that the permanent magnet outer stator 5 adopts a built-in tangential magnetic steel structure or a surface-mounted magnetic steel Structural realization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com