Film laminated ophthalmic lenses with improved wheel edging performance

A lens and edging technology, applied in glasses/safety glasses, glasses/goggles, instruments, etc., can solve the problems of film separation and deformation, avoid film deformation and/or avoid film separation, and overcome standard grinding wheels The effect of edge defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

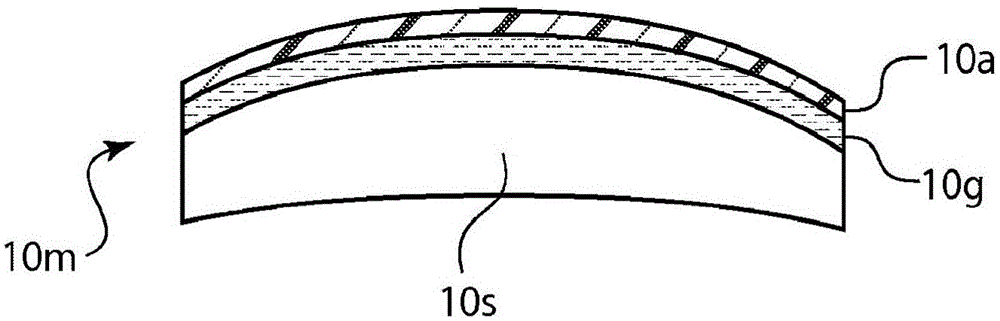

[0043] Simple monofilm laminate with improved edging properties

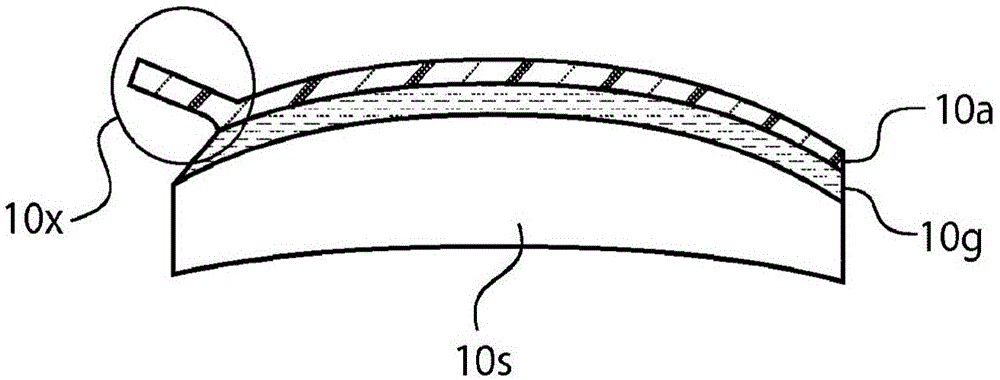

[0044] Figure 1A and image 3 is a comparative example of simple film lamination. In FIG. 1A a simple thin TAC film 10a is laminated to a lens 10s by a thin layer of PSA adhesive 10g. The thickness of the film 10a is approximately 40 microns, and the thickness of the adhesive layer 10g is 25 microns. Laminated lenses 10m with these thin layers produced poor edging results. In other words, as shown in Figure IB, the laminated lens 10m will have an unacceptably high percentage of defects.

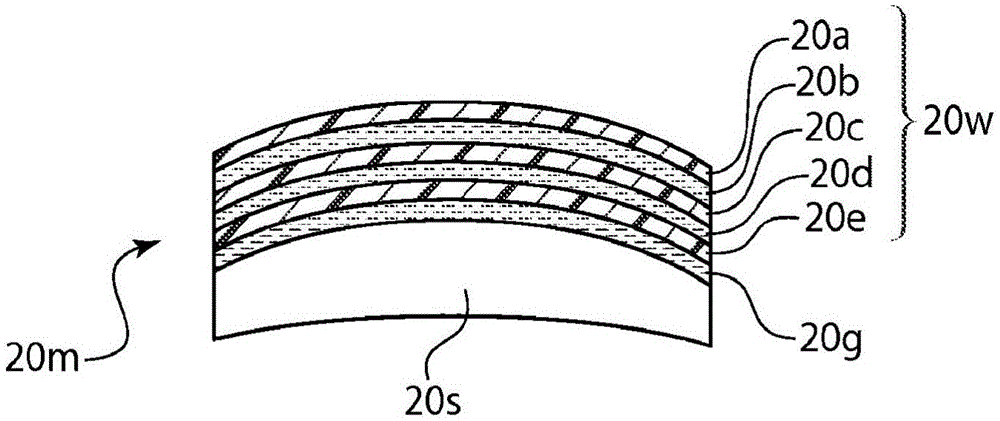

[0045] exist image 3 In this case, a simple thick TAC film 34a is laminated to a lens 34s by a thick layer of PSA adhesive 34g. The thickness of the film 34a is approximately 190 microns, and the thickness of the adhesive layer 34g is 25 microns. Laminated lenses 34m with these thick layers produced good edging results. In other words, the laminated lens 34m will have a low or no defect percentage.

[0046] We have gone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com