Method for processing fibre material

A fiber material and fiber technology, which is applied in the field of processing fiber materials, can solve the problems of unsuitable production process, energy consumption and quality characteristics reaching the theoretical optimal value, etc., and achieve the effects of saving refining energy consumption, rapid refining, and extensive process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

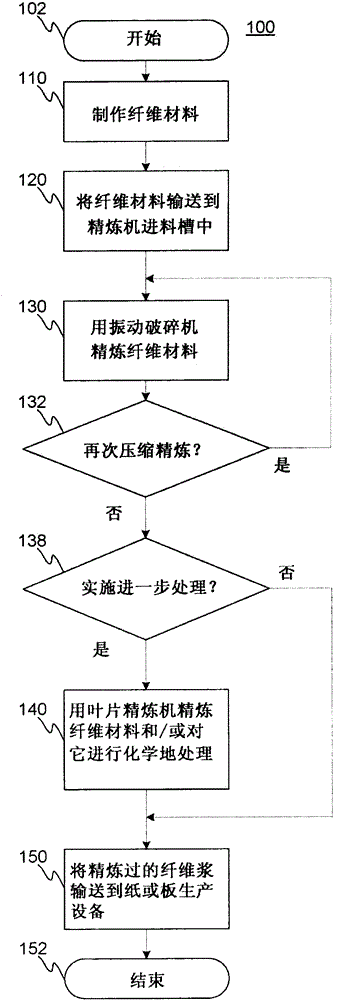

[0022] figure 1 A method 100 is shown for processing fibrous material, such as wood chips or wood pulp, i.e. cellulosic pulp used in the manufacture of fibrous products such as paper or board, in such a way that the fibrous material is refined , to facilitate pulping and / or chemical processing of fibrous materials.

[0023] Initiation step 102 includes: providing raw material for wood pulp; starting machines and equipment for producing, processing and moving wood pulp.

[0024] By using eg birch, spruce or pine as raw material, step 110 involves producing wood chips or wood pulp comprising wood fibers individually or in contact with each other.

[0025] In the case of so-called green tube pulp, in step 120 the wood pulp produced is transported to the paper and / or pulp mill, eg by pumping along purpose-built pipelines, directly into the refiner tanks to await refining. Alternatively, where the produced wood pulp is dried into bales for transport and / or storage, the dried bale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com