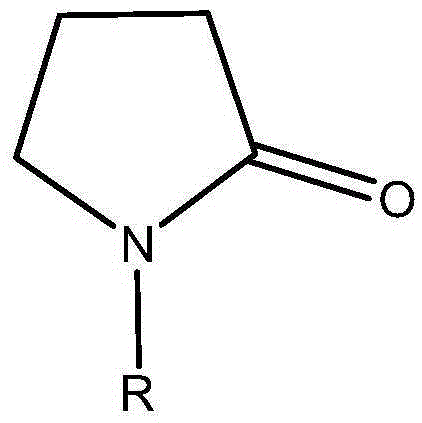

Production method of pyrrolidone products

A pyrrolidone and production method technology, applied in the production field of pyrrolidone products, can solve problems such as increased yield, high yield, and short process, and achieve the effects of shortened production process, high product yield, and reduced process energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

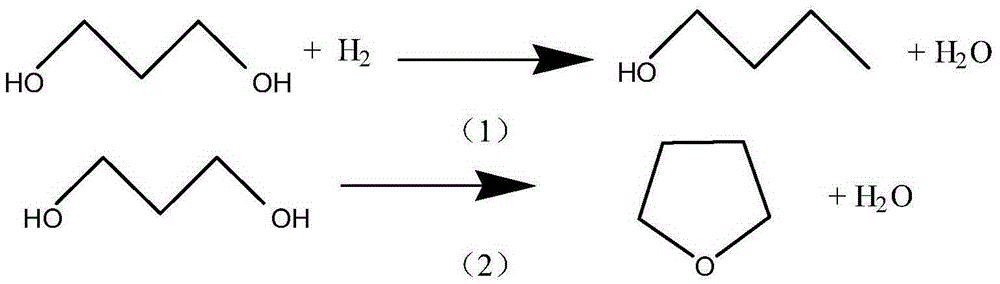

Method used

Image

Examples

Embodiment 1

[0034] The present embodiment is a production method of pyrrolidone products, comprising:

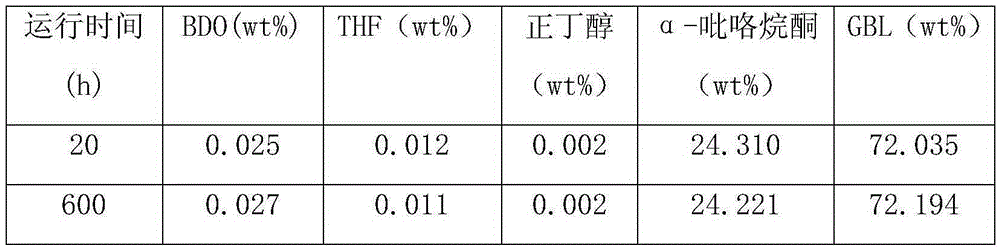

[0035] Raw materials: 1,4-butanediol (99.9wt%, produced by Xinjiang Meike Chemical Industry Co., Ltd.) and ammonia water (25%) respectively enter the mixer through the metering pump according to the molar ratio of 1:1.5, and are preheated by the preheater E-101 To 195 ° C, a well-insulated tubular reactor R101 (inner diameter 300mm), the internal filling catalyst is to contain 50wt% Cu1.5wt% CaO-3wt% BaO-10wt% ZnO-30wt% SiO 2 (No. BIPT-NMP-011), the balance is crystal water, spherical (particle size 2mm), the filling volume is 100L, the feeding volume is 80L / h, the temperature measurement display value in the reactor is 195~198℃, indicating that the temperature distribution is uniform , Pressure back pressure control 3.0MPa. The product exported from R101 is pumped into the preheater E102 through the liquid level controller to adjust the metering pump in the buffer tank V101. The sampl...

Embodiment 2

[0043] The present embodiment is a production method of pyrrolidone products, comprising:

[0044] Raw materials: 1,4-butanediol (99.9wt%, produced by Xinjiang Meike Chemical Industry Co., Ltd.) and monomethylamine aqueous solution (37%) respectively enter the mixer through the metering pump according to the molar ratio of 1:2.0, and pass through the preheater E- 101 is preheated to 205°C, a slurry bed reactor R101 (effective volume 50L, 30LNMP is installed inside at the beginning of the reaction), and the internal loading catalyst is 25wt%Cu5wt%ZrO 2 -3wt%BaO-40wt%SiO 2 (No. BIPT-NMP-021), the balance is crystal water, powder (average particle size 80 microns), the filling volume is 2L, the feeding volume is 3L / h, the temperature measurement display value in the reactor is 202~205℃, the pressure Back pressure control 3.8MPa. The product exported from R101 is pumped into the preheater E102 through the liquid level controller to adjust the metering pump in the buffer tank V10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com